Aluminum nitride ceramic composite material and preparation method thereof

A technology of aluminum nitride ceramics and composite materials, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

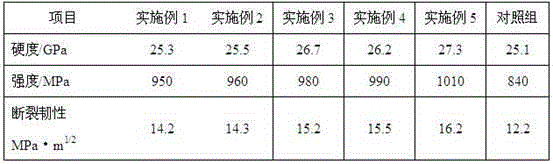

Examples

Embodiment 1

[0025] An aluminum nitride ceramic composite material, comprising the following components in parts by mass:

[0026] 60 parts of aluminum nitride, 15 parts of nano-alumina, 8 parts of boron nitride, 15 parts of carbon fiber, 8 parts of nano-titanium oxide, 7 parts of nano-tin oxide, 6 parts of zirconia, 5 parts of cobalt powder and 12 parts of yttrium oxide.

[0027] According to the preparation method of the aluminum nitride ceramic composite material provided by the present invention, the above-mentioned composite material is prepared, and the steps are as follows:

[0028] (1) Accurately weigh each component in corresponding parts by mass;

[0029] (2) Mix each component evenly and put it into a ball mill for grinding until it is evenly mixed to obtain a mixed powder;

[0030] (3) Put the mixed powder into a high-temperature furnace for high-temperature and high-pressure calcination at a temperature of 1400°C and a pressure of 4.5GPa for 5 hours;

[0031] (4) After the c...

Embodiment 2

[0033] An aluminum nitride ceramic composite material, comprising the following components in parts by mass:

[0034] 35 parts of aluminum nitride, 10 parts of nano-alumina, 6 parts of boron nitride, 8 parts of carbon fiber, 3 parts of nano-titanium oxide, 3 parts of nano-tin oxide, 3 parts of zirconia, 2 parts of cobalt powder and 6 parts of yttrium oxide.

[0035] According to the preparation method of the aluminum nitride ceramic composite material provided by the present invention, the above-mentioned composite material is prepared, and the steps are as follows:

[0036] (1) Accurately weigh each component in corresponding parts by mass;

[0037] (2) Mix each component evenly and put it into a ball mill for grinding until it is evenly mixed to obtain a mixed powder;

[0038] (3) Put the mixed powder into a high-temperature furnace for high-temperature and high-pressure calcination at a temperature of 1400°C and a pressure of 3.5GPa for 6 hours;

[0039] (4) After the cal...

Embodiment 3

[0041] An aluminum nitride ceramic composite material, comprising the following components in parts by mass:

[0042] 45 parts of aluminum nitride, 12 parts of nano-alumina, 7 parts of boron nitride, 12 parts of silicon carbide fiber, 6 parts of nano-titanium oxide, 5 parts of nano-tin oxide, 5 parts of zirconia, 3 parts of cobalt powder and 11 parts of praseodymium oxide .

[0043] According to the preparation method of the aluminum nitride ceramic composite material provided by the present invention, the above-mentioned composite material is prepared, and the steps are as follows:

[0044] (1) Accurately weigh each component in corresponding parts by mass;

[0045] (2) Mix each component evenly and put it into a ball mill for grinding until it is evenly mixed to obtain a mixed powder;

[0046] (3) Put the mixed powder into a high-temperature furnace for high-temperature and high-pressure calcination at a temperature of 1400°C and a pressure of 3.5GPa for 5 hours;

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com