Back column upper decoration plate and mold and injection molding method thereof

A technology for a decorative plate and a rear pillar, which is applied to the decorative plate on the rear pillar and its mold and injection molding fields, can solve problems such as inability to solve surface air trapping, and achieve the effects of simple structure, low cost, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

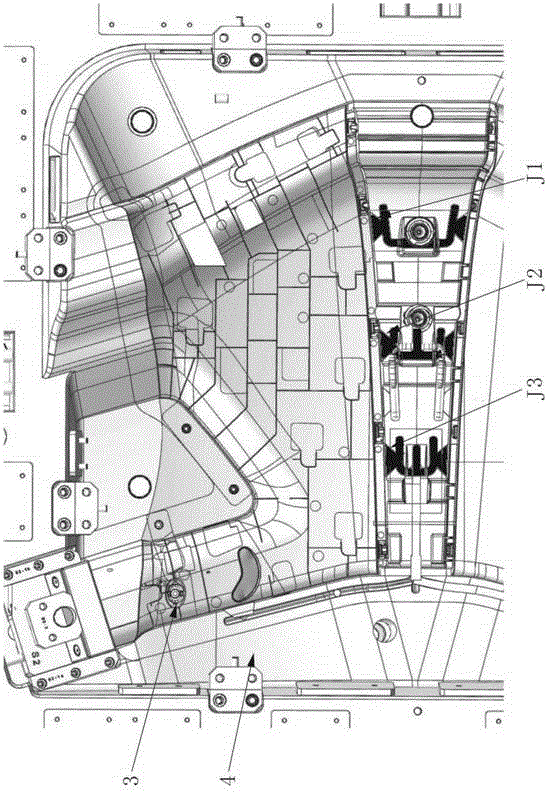

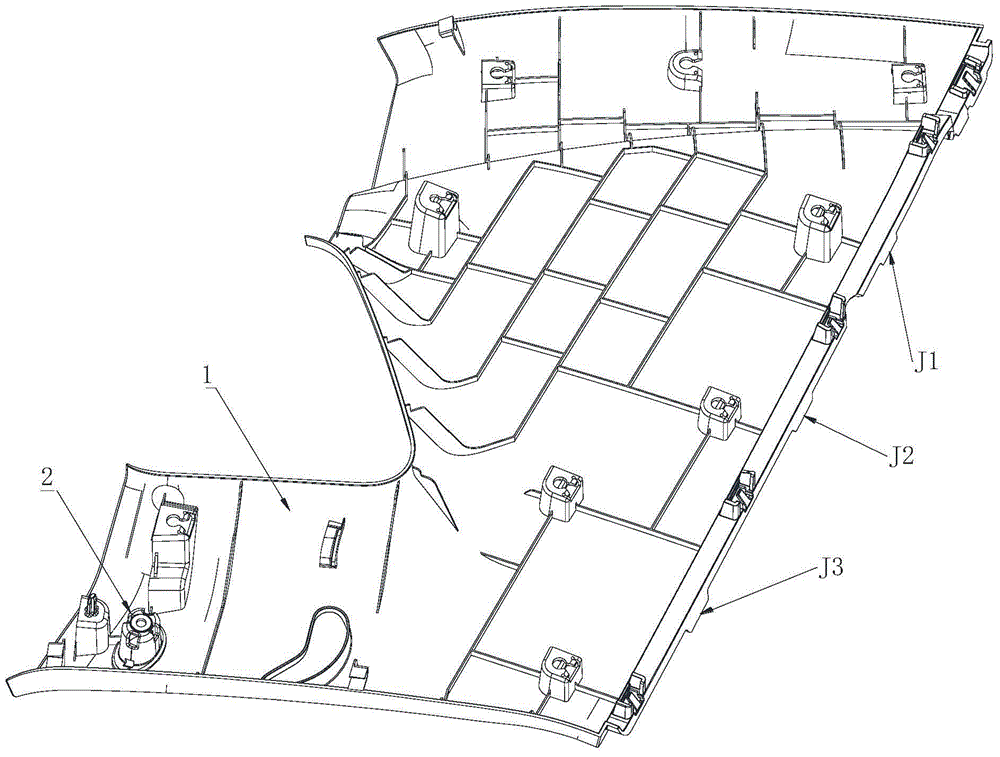

[0038] Such as Figure 4 As shown, the decorative plate 1 on the rear pillar has improved the deep hole structure 2, and cleverly connects the original two pillar decoration cover hook holes 23 with the two mounting screw lookout holes 22 corresponding to their respective positions, thereby forming a structure for Blocking material flow 3. the choke hole 24 that flows through in the deep hole.

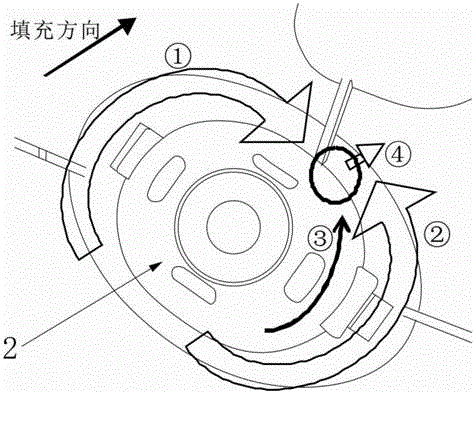

[0039] Such as Figure 5 As shown, the improved deep hole structure 2 changes the filling order of the material, so that the two strands of material ① and ② converge first, and then flow downward—forming material flow ③, ④—converging at the bottom of the deep hole structure cavity 31 , here is the exhaust position of the deep hole structure movable mold 3, which solves the defect of trapped air. After mold modification, the mold test was verifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com