Fixed-length drawing composite technology and equipment

A technology of fixed-length stretching and composite technology, which is applied in printing, rotary printing machines, printing machines, etc., can solve the problems of laser image and text version length error, fluctuation, and subsequent processing of laser paper products cannot be carried out smoothly, and achieve a reduction in version. Long error, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

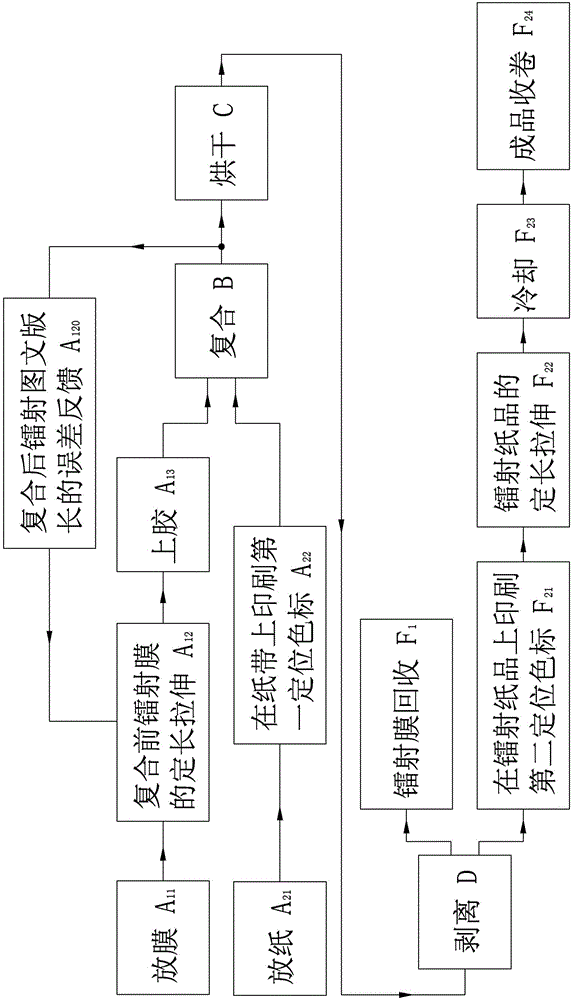

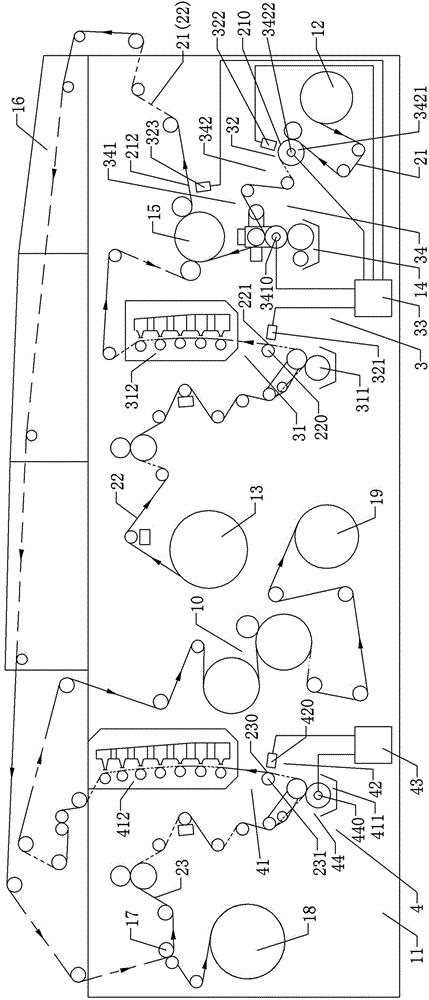

[0072] like figure 1 As shown, the fixed-length drawing composite process in this preferred embodiment is characterized in that comprising:

[0073] Release film A 11 : Install the film roll, and output the laser film on the film roll, and the lamination surface of the laser film has laser graphics with the same version length;

[0074] Put paper A 21 : install the paper roll, and output the paper tape on the paper roll;

[0075] Print the first positioning color mark A on the paper tape 22 : Print the first positioning color mark on the pressing surface of the paper tape, the length of the first positioning color mark is greater than the length of the laser graphic version of the laser film;

[0076] Fixed-length stretching of laser film before compounding A 12 ; According to the length of the first positioning color mark on the paper tape, by controlling the conveying speed of the laser film before the composite, the laser film before the composite is stretched to a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com