A magnetic plate fabric printing device

A printing device and magnetic plate technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of cumbersome finishing process, increase of production cost, long printing and dyeing and printing preparation process, and achieve convenient printing and dyeing preparation process and excellent workmanship. The effect of simple process and fast printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

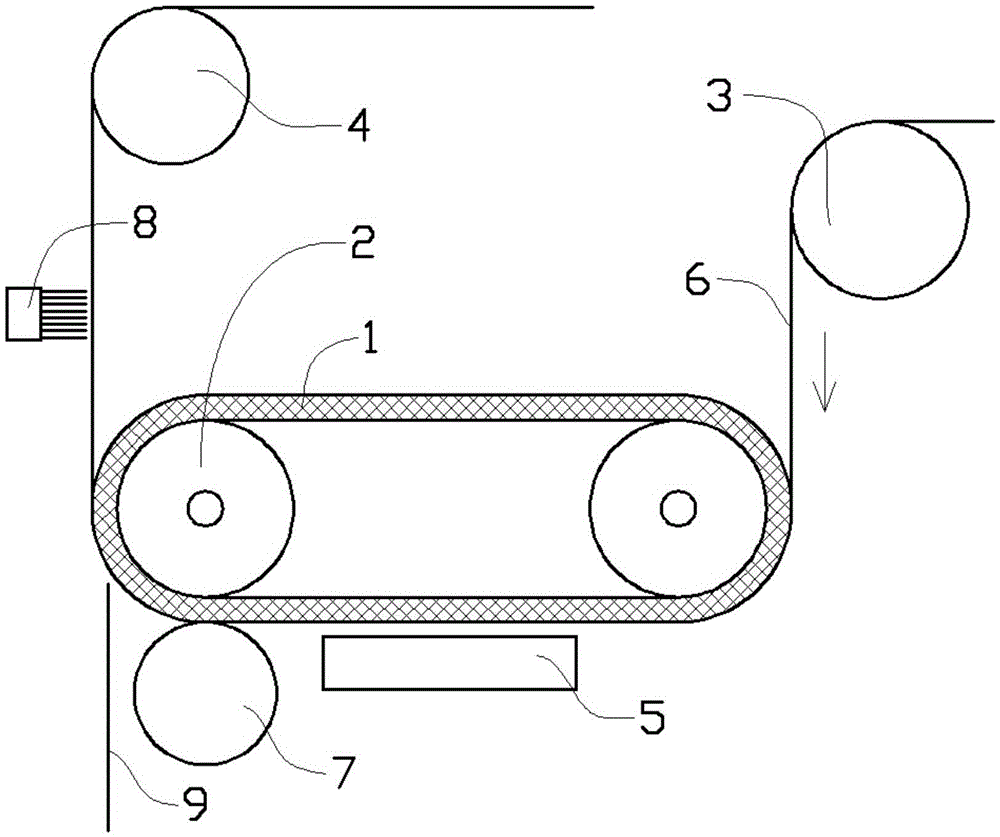

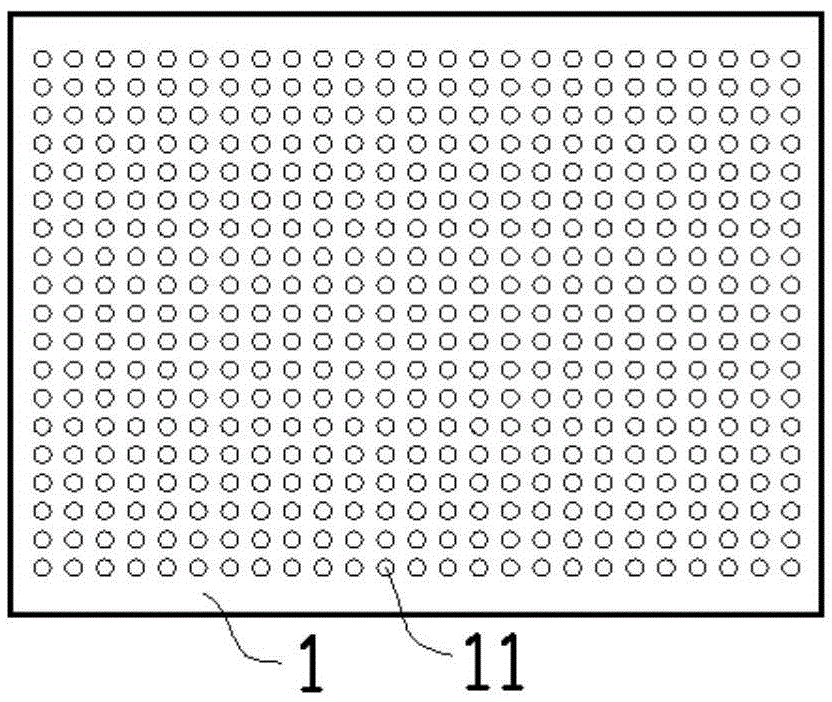

[0012] Such as figure 1 and figure 2 As shown in the embodiment, the magnetic plate fabric printing device includes a magnetic belt 1, a transmission wheel 2, a cloth feed wheel 3, and a cloth output wheel 4; the transmission wheels 2 are used in pairs and placed side by side horizontally, and the magnetic belt 1 It is in the shape of an endless belt and is made of deformable elastic material. The two ends of the magnetic belt 1 bypass the transmission wheel 2 and are stretched by the transmission wheel 2 to form an upper and lower plane. The transmission wheel 2 is connected with the transmission structure of the equipment , the outer surface of the magnetic belt 1 is equipped with a magnetic block 11, the lower part of the magnetic belt 1 is designed with a dye tank 5, and the inside of the dye tank 5 is tiled with a mixed material of dye powder and magnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com