Cutter body end surface positioning groove machining tooling

A positioning groove and cutter body technology, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems that affect the processing quality and the position height of the grinding wheel cannot meet the processing requirements, so as to achieve convenient grinding wheel processing, easy processing, The effect of reducing the positioning height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

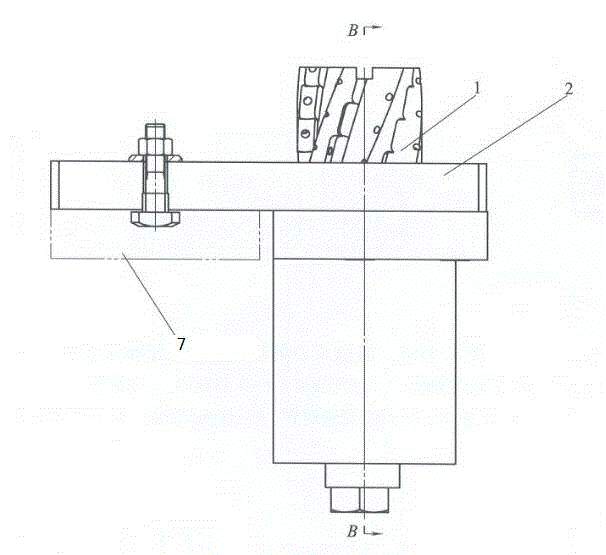

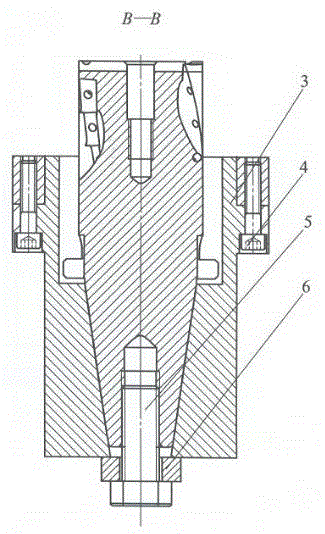

[0013] The reference signs in the accompanying drawings of the description include: cutter body 1, positioning plate 2, counterbore sleeve 3, fastening screw 4, fastening bolt 5, gasket 6, machine tool table 7.

[0014] as attached figure 1 and 2 As shown: the lower surface of one side of the positioning plate 2 is disassembled and connected to the machine tool table through bolts, and a through hole is opened on the other side of the positioning plate 2, and the counterbore sleeve 3 is axially positioned in the through hole. The upper surface of the hole sleeve 3 is on the same plane as the upper surface of the positioning plate 2 .

[0015] The counterbore sleeve 3 is provided with an upper circular hole and a lower taper hole whose taper matches the outer taper of the cutter along its axial direction. The taper of the lower taper hole is 7:20. The outside gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com