Permanent magnet motor stator

A permanent magnet motor and stator technology, applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of low production efficiency, uncompact structure, large interval width, etc., and achieve high production efficiency, compact structure, and small interval width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

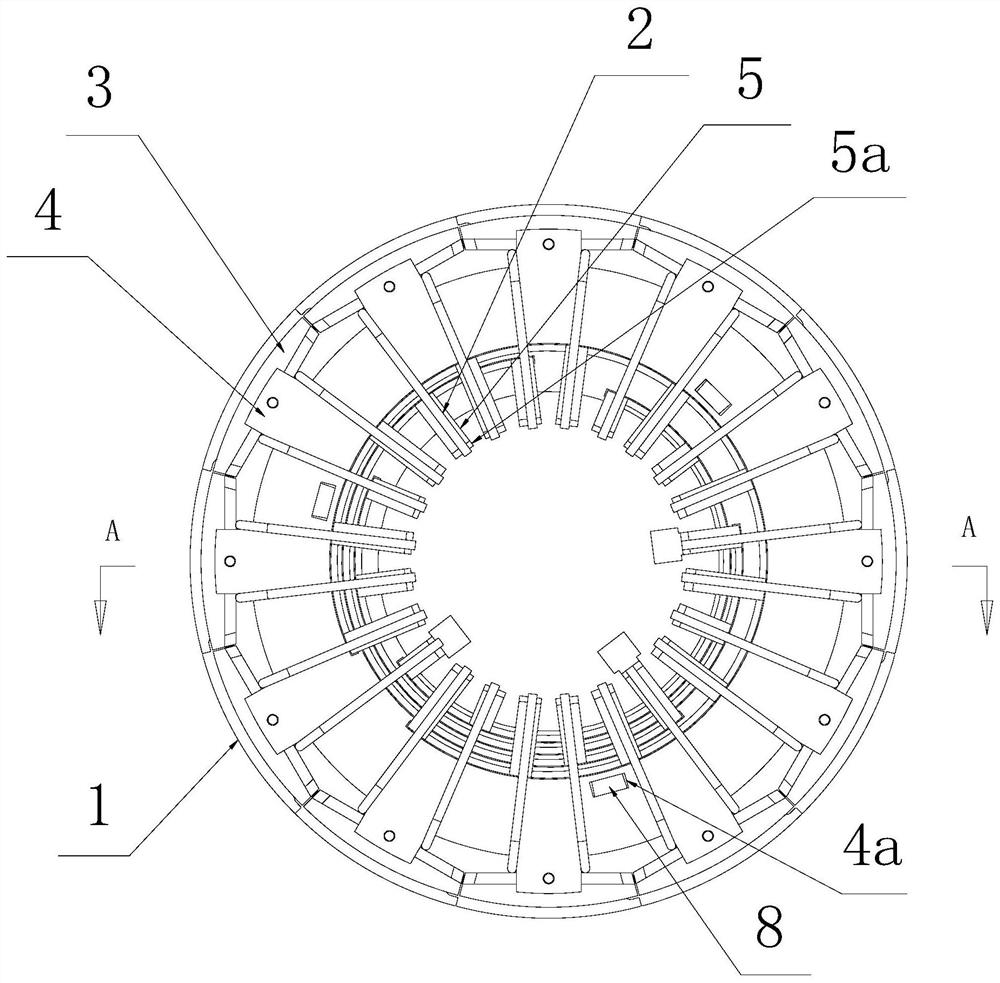

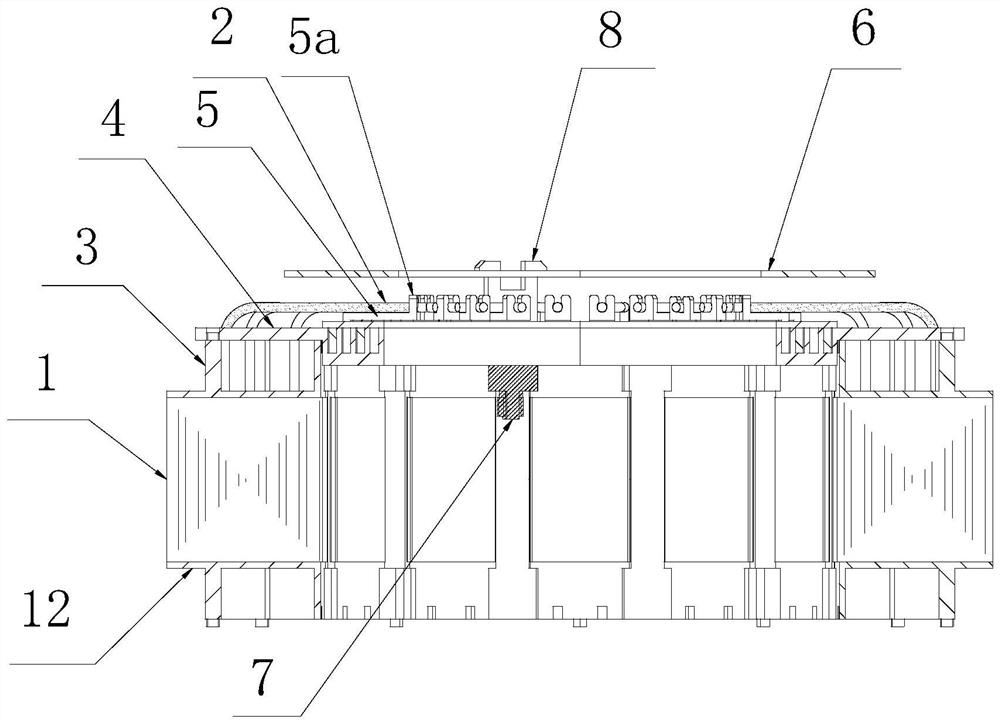

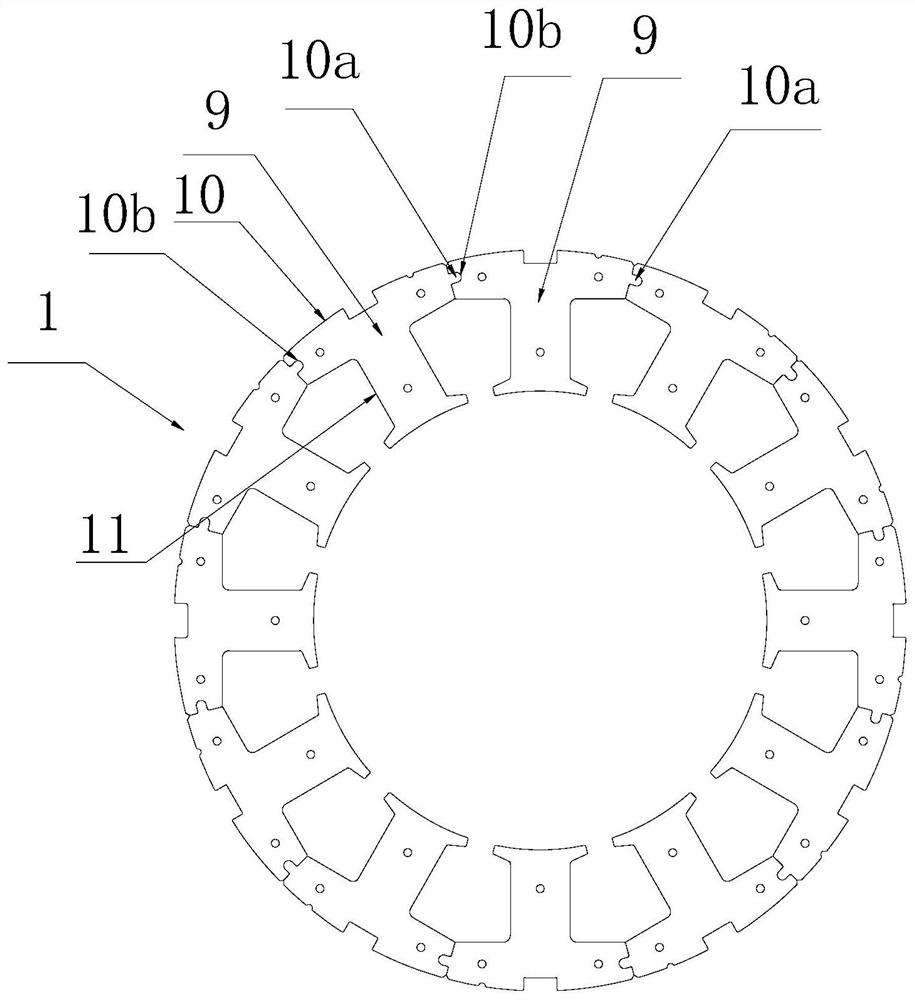

[0025] Embodiment: combine below Figure 1~Figure 3 The specific implementation of the permanent magnet motor stator provided by the present invention is described as follows:

[0026] The stator of this permanent magnet motor is the same as the conventional technology, and its whole consists of a stator core 1, a winding wound on each tooth portion 11 inside the stator core 1, and a wiring structure for connecting the winding lead-out wire 2 with the power line. and Hall components together. The stator core 1 in this embodiment is a segmented stator core formed by annular splicing of twelve core unit blocks 9, and each core unit block 9 is composed of a peripheral yoke part 10 and a yoke part 10 connected teeth 11 constitute a specific combination image 3 As shown, the two sides of the yoke part 10 of each iron core unit block 9 are respectively provided with a convex key 10a and a groove 10b matching the convex key 10a, and two adjacent iron core unit blocks 9 on the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com