Precise numerical control double housing surface milling and grinding complex machine tool of floor working table elevated horizontal beam movable type structure

A technology of precision CNC and compound machine tools, applied in the field of machining, can solve the problems of huge cost, regular replacement of hydraulic oil, and high oil consumption of hydraulic stations, and achieve the effect of improving work efficiency and saving clamping and transfer time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

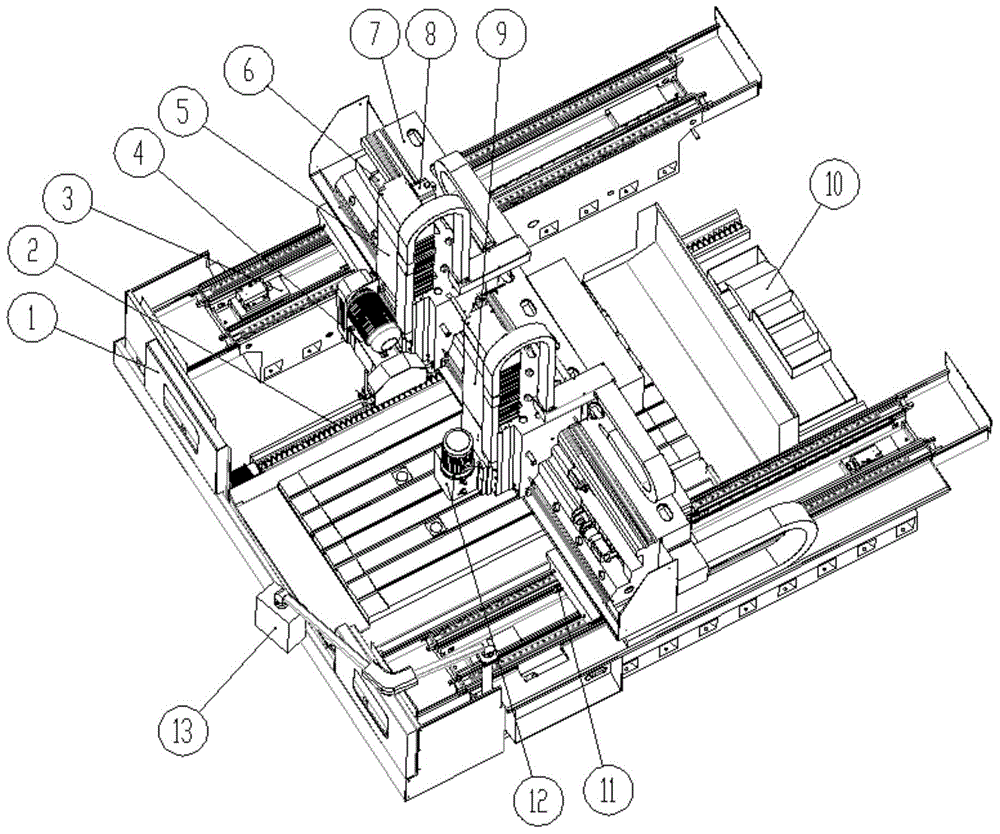

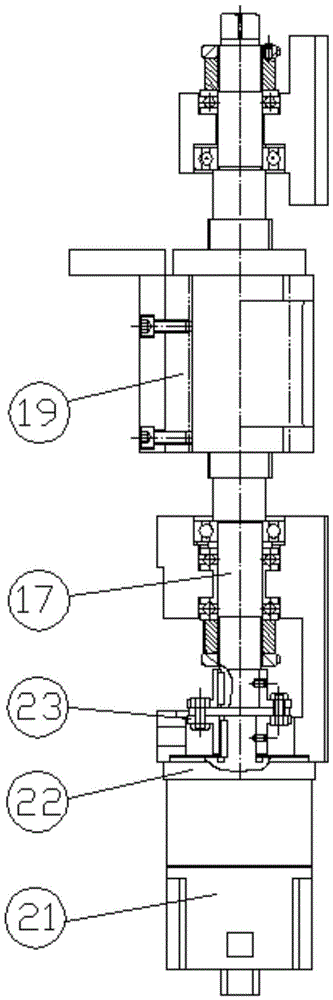

[0021] like figure 1 , 2 As shown in and 3, a precision CNC gantry plane milling-grinding compound machine tool with a floor-to-ceiling workbench elevated crossbeam mobile structure, including a double-wide base bed 3, a viaduct-type movable beam 7, a vertical feed mechanism 8, a longitudinal transmission mechanism 11, The milling head 12 and the electric control system 13 are provided with linear guide rails on both sides of the double-wide base bed 3, the longitudinal transmission mechanism 11 is arranged on the linear guide rails, and the viaduct type movable beam 7 is in the on the linear guide rail, and the longitudinal transmission mechanism 11 drives the viaduct-type movable beam 7 to perform longitudinal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com