Simple device for expanding deep holes and cooling and chip removal method

A deep hole, simple technology, applied in the direction of feeding device, boring/drilling, maintenance and safety accessories, etc., can solve the problems of low processing efficiency, high processing cost, high cost, etc., to achieve improved efficiency, simple structure, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

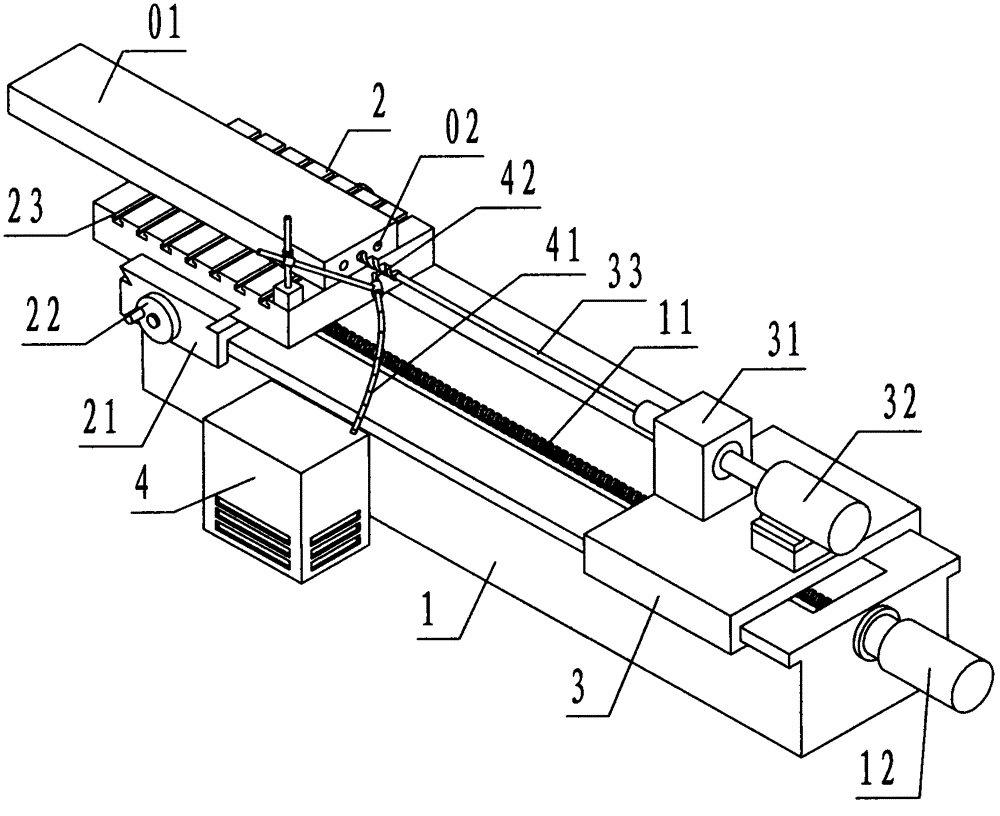

[0019] refer to figure 1 , a simple device for deep hole expansion and a cooling and chip removal method of the present invention, comprising a bed 1, a workbench 2, a mobile drill floor 3, and a pulse compressed air source 4, wherein: the bed 1 is rectangular in plan view The frame-shaped cast iron components, the top of the front and rear groove frames of the bed 1 are smooth rails in the left and right directions called longitudinal slide rails, and the groove cavity of the bed 1 is provided with a screw parallel to the longitudinal slide rails. It is a longitudinal lead screw pair 11, and the right side of the bed 1 is fixedly provided with a servo motor called a feed motor 12; the output shaft of the feed motor 12 is connected to the right end of the leading screw of the longitudinal lead screw pair 11; The lead screw pair is a mechanical element composed of a lead screw and a nut that converts rotational motion into linear motion;

[0020] The workbench 2 is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com