External-circulating ball roller way-type mill

A roller type, external circulation technology, applied in grain processing and other directions, can solve problems such as low processing efficiency, and achieve the effects of uniform load, high efficiency and reduced total power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

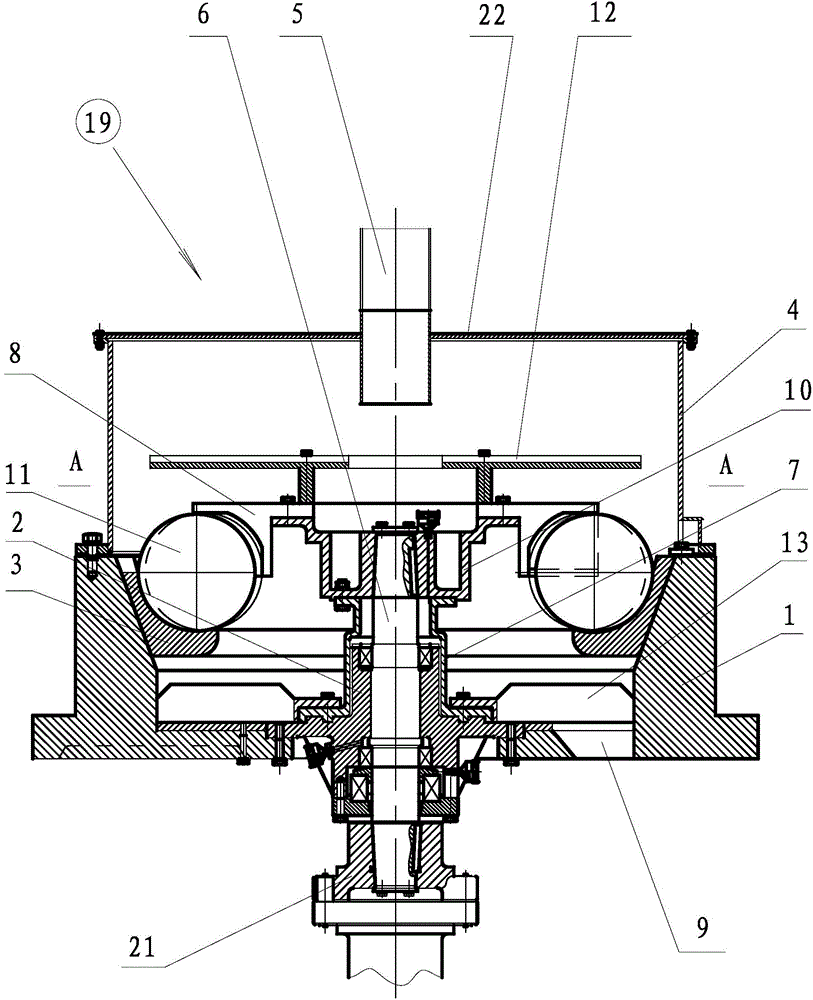

[0024] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

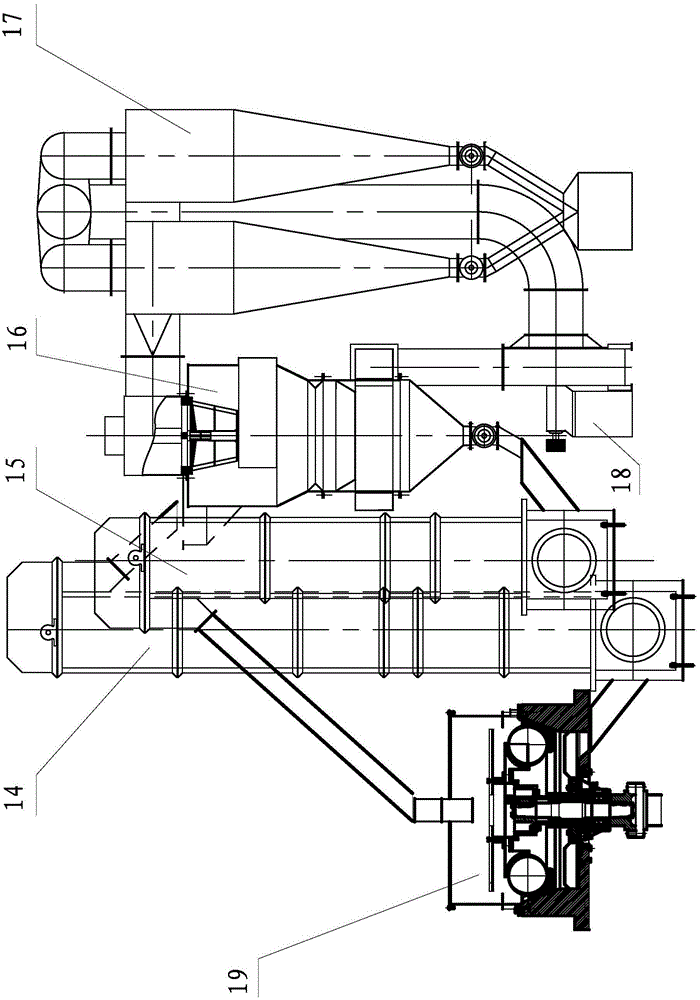

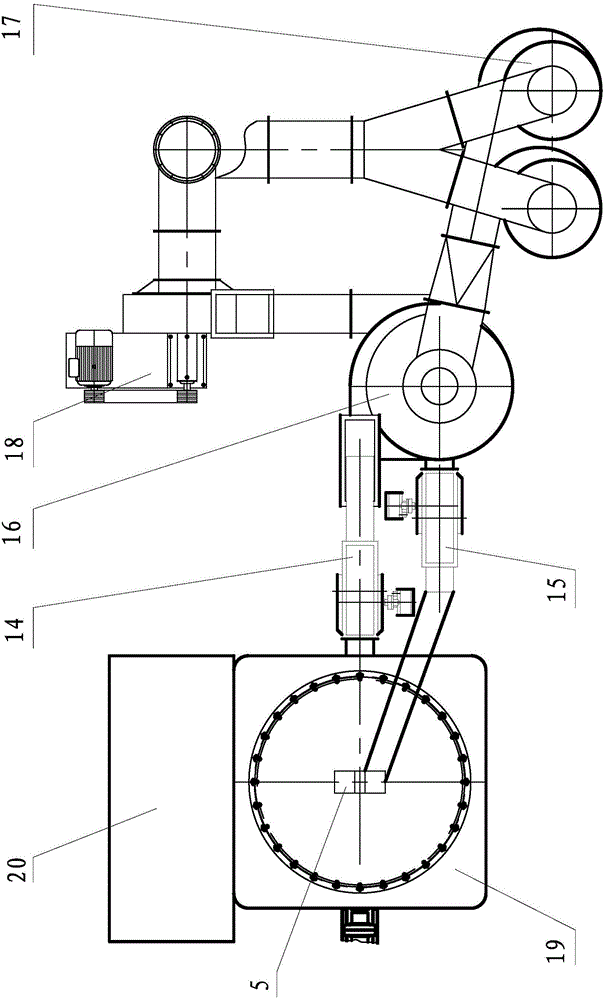

[0025] The outer circulation ball roller mill of the present invention includes a milling host 19 and an external classification system.

[0026] The base 1 of the main mill 19 is fixed on the concrete base, the bottom of the inner hole of the base 1 is coaxially equipped with a hollow central shaft frame 2, and the upper part of the inner hole of the base 1 is coaxially installed with a grinding ring 3, and the grinding ring 3 The grinding surface is a 1 / 4 circular surface, and a cover cylinder 4 is coaxially installed on the end surface of the base 1. The cover cylinder 4 is covered by an upper cover 22, and the center of the upper cover 22 is provided with a feeder for the milling host 19. port 5; the lower part of the main shaft 6 of the milling main machine 19 is installed in the central shaft frame 2 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com