A method for preparing capsule shells from glycosylated modified zein

A technology of zein and glycosylation, which is applied in the fields of capsule delivery, non-active ingredients of polymer compounds, food science, etc., can solve the problem of high chemical residues, achieve high grafting degree, good effect, and good moisture resistance Effect of Oxygen Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

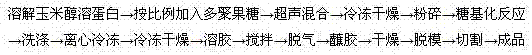

Method used

Image

Examples

Embodiment 1

[0017] Step 1: Take 10 g of zein with a purity of 90%, dissolve it with 80% ethanol solution to obtain a prolamin dispersion, add 35 mL of polyfructose with a concentration of 0.2 g / mL and a purity of 95%, and add ethanol Solution, so that the total system is 100mL, heating and magnetic stirring at 75°C, and preparing a mixed solution for 30min, so that the final concentration of zein is 10%.

[0018] Step 2: Ultrasonic the dispersion liquid at 300W, mix it for 20 minutes, vacuum freeze-dry the uniformly dispersed mixed liquid, and crush it through a 100-mesh sieve after drying.

[0019] Step 3: Place the dry sample powder at 75°C and 80% relative humidity (maintained with saturated KBr solution) to react for 96 hours, wash repeatedly with distilled water, centrifuge to remove residual polyfructose and other impurities, and freeze-dry to obtain modified zein Sample, the degree of grafting of glycosylated products is more than 20%.

[0020] Step 4: Dissolve the modified zein p...

Embodiment 2

[0022] Step 1: Take 9 g of zein with a purity of 90%, dissolve it with 80% ethanol solution to obtain a prolamin dispersion, add 15 mL of polyfructose with a concentration of 0.2 g / mL and a purity of 95%, and add ethanol solution, so that the total system was 100 mL, heated and magnetically stirred at 80°C, and prepared a mixed solution for 30 minutes, so that the final concentration of zein was 9%.

[0023] Step 2: Sonicate the dispersion at 400W, mix for 15 minutes, vacuum freeze-dry the uniformly dispersed mixture, and crush it through a 100-mesh sieve after drying.

[0024] Step 3: Place the dry sample powder at 80°C and 78% relative humidity (maintained with saturated KBr solution) to react for 54 hours, wash repeatedly with distilled water, centrifuge to remove residual polyfructose and other impurities, and freeze-dry to obtain modified zein Sample, the degree of grafting of glycosylated products is more than 20%.

[0025] Step 4: Dissolve the modified zein powder into...

Embodiment 3

[0027] Step 1: Take 10 g of zein with a purity of 90%, dissolve it with 80% ethanol solution to obtain a prolamin dispersion, add 30 mL of polyfructose with a concentration of 0.2 g / mL and a purity of 95%, and add ethanol Solution, make the total system 100mL, heat and magnetically stir at 70°C, and prepare the mixed solution for 30min, so that the final concentration of zein is 10%.

[0028] Step 2: Ultrasonic the dispersion liquid at 400W, mix for 20 minutes, vacuum freeze-dry the uniformly dispersed mixed liquid, and crush through a 100-mesh sieve after drying.

[0029] Step 3: Place the dry sample powder at 70°C and 70% relative humidity (maintained with saturated KBr solution) to react for 180 hours, wash repeatedly with distilled water, centrifuge to remove residual polyfructose and other impurities, and freeze-dry to obtain modified zein Sample, the degree of grafting of glycosylated products is more than 20%.

[0030] Step 4: Dissolve the modified zein powder into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com