A kind of synbiotic feed additive and its application

A feed additive and synbiotic technology, applied in application, animal feed, animal feed, etc., can solve the problem of unstable effect, and achieve the effect of reducing the incidence of disease, resistant to processing shelf life, inhibiting and controlling diarrhea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides the preparation process of inactivated Lactobacillus salivarius and its fermentation product:

[0036] (1) Take Lactobacillus salivarius, use the conventional Lactobacillus culture medium (liquid MRS medium) in the field to make fermentation broth through conventional fermentation, centrifuge the fermentation broth, separate Lactobacillus salivarius cells and post-fermentation culture fluid ;

[0037](2) Take 4kg of Lactobacillus salivarius cells obtained after centrifugation, add 16L of sterile saline at about 40°C, stir well (do not stir violently) and mix evenly to make a suspension, heat it with steam, and pass it through Stir while steaming, and control the steam flow, so that the heating rate is controlled at about 1.5°C / min. After 20 minutes, the temperature rises to 70°C. Reduce the steam supply and start timing to keep warm. After 10 minutes, stop steaming and heat the bacterial suspension. Pour into 20kg of crushed ice, mix evenly so ...

Embodiment 2

[0042] (1) Get Lactobacillus salivarius, adopt conventional culture medium (liquid MRS culture medium) to make fermented bacterial liquid by fermentation;

[0043] (2) Concentrate 1000L of the fermented bacteria solution prepared in step (1) directly by thin film evaporation, lose 80% of water to 200L, then cool down to below 40°C, add 43kg each of maltodextrin and soluble starch, stir and mix evenly . Set the inlet temperature of the spray dryer to 170°C, the outlet temperature to 68°C, the feeding flow rate to be constant, and the compressor pressure to be 0.4Mpa. After drying, collect Lactobacillus salivarius and its fermented products, and check the number of lactic acid bacteria unit cells with a staining microscope.

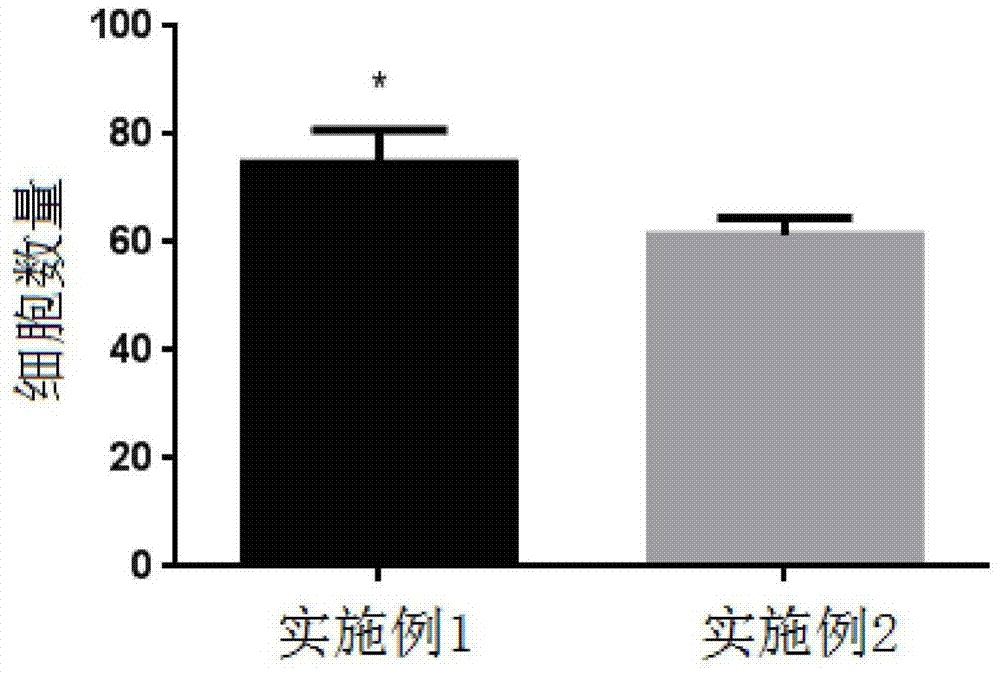

[0044] Then carry out staining microscopic examination counting by the method for embodiment 1, compare the impact of two different methods in embodiment 1 and embodiment 2 on the integrity of Lactobacillus salivarius cells in Lactobacillus salivarius and i...

Embodiment 3

[0047] (1) Get Lactobacillus casei, adopt conventional culture medium to ferment and make fermented bacterial liquid (tomato juice culture medium), fermented bacterial liquid is centrifuged, isolates Lactobacillus casei thalline cell and cultured liquid after fermentation;

[0048] (2) Take 4kg of Lactobacillus casei cells obtained after centrifugation, add 14L of sterile saline at about 35°C, stir well (do not stir violently) and mix evenly to make a suspension, heat with steam, and pass through Stir while steaming, and control the steam flow, so that the heating rate is controlled at about 1°C / min. After 15 minutes, the temperature rises to 65°C. Reduce the steam supply and start timing to keep warm. After 10 minutes, stop steaming and heat the bacteria suspension. Pour into 20kg of crushed ice, mix evenly so that the temperature quickly drops below 30°C to obtain a cooled Lactobacillus casei suspension;

[0049] (3) Take 1000L of the fermented culture fluid separated in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com