Winding unitized parallel winding structure of alternating current motor stator winding

An AC motor and stator winding technology, applied in the shape/style/structure of the winding conductor, can solve the problems of increasing the length of the wire at the end of the winding, increasing the copper loss of the motor, and increasing the resistance of the winding, so as to improve the motor efficiency, The effect of saving materials and reducing winding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below through specific embodiments.

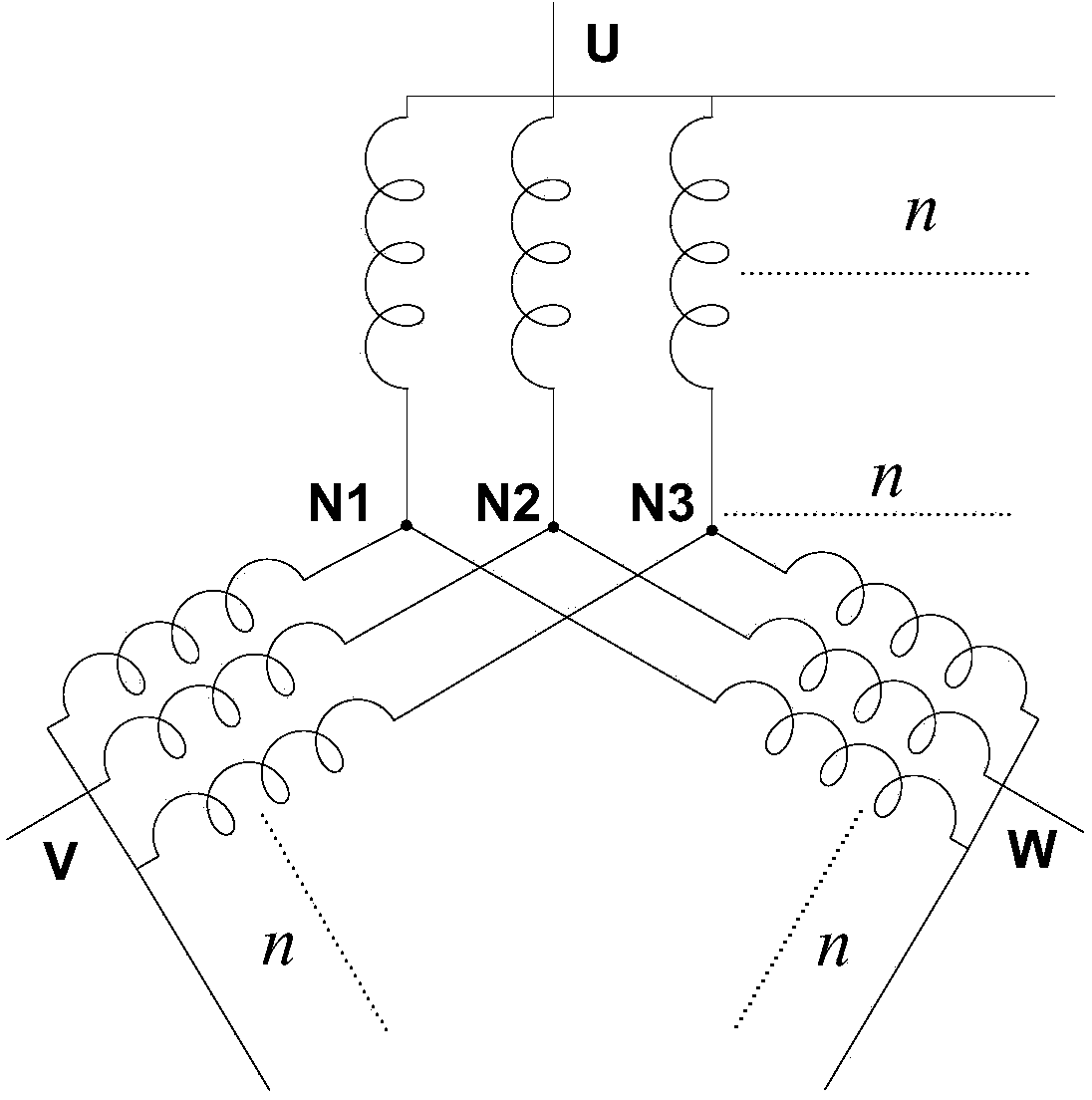

[0023] The AC motor stator winding unitized parallel winding structure of the present invention, the structure of the AC motor stator adopts a centralized winding structure and a star connection structure in which each phase winding branch is independent of each other and each phase winding branch is connected in parallel; specifically: multi-stage multi- The number of phases of a phase AC motor is m, the number of stator slots is Z, the number of pole pairs is p, and Z can divide m; the stator slots are divided into Z / m units, each unit contains m teeth, and m teeth A parallel branch of m phases is respectively wound, and the tail ends of the parallel branches wound by m teeth on each unit are connected to form a neutral point of a star connection, and the Z / m units form a Z / m An independent unconnected neutral point; and the first ends of each phase winding of each unit are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com