Torsion tester for cable branch box, and test method thereof

A junction box and testing machine technology, which is applied in the direction of applying stable torque to test the strength of materials, can solve the problems of inability to guarantee the safety of testers, inability to guarantee the accuracy of the test, and poor applicability, and achieve the safety of the test process. Reliable, guaranteed strength, accurate force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

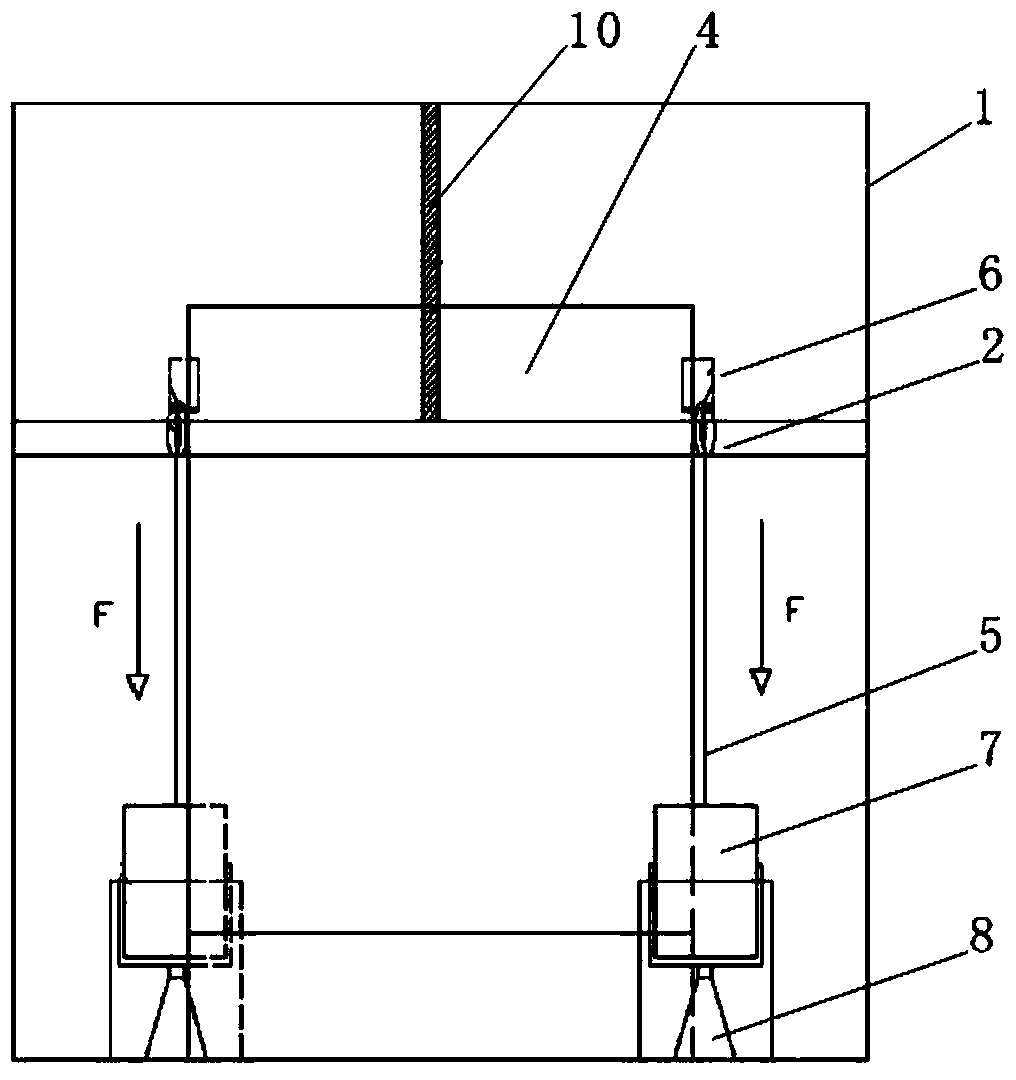

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0023] A cable junction box torque testing machine, including a base 9, a main frame 1, a beam 2, a slider 3, a pulley 6, a heavy load 7, a pulley 6, a steel cable 5, and a jack 8, which are installed on the base for fixing For the fixture of the tested sample 4, a main frame is installed above the base, and cross beams are installed horizontally and horizontally on both sides of the front and rear sides of the corresponding main frame above the base;

[0024] In order to be suitable for measuring cable box samples of different sizes, the crossbeam adopts an up-and-down oriented longitudinal adjustment structure. Specifically, the middle parts of both ends of the crossbeam on both sides are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com