A sealing gasket for refrigeration equipment

A technology for sealing gaskets and refrigeration equipment, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor performance, inconvenient installation and use, rubber easily sticking to the sealing surface, etc., to achieve flame retardancy and Good anti-corrosion effect, excellent cold resistance and excellent total performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

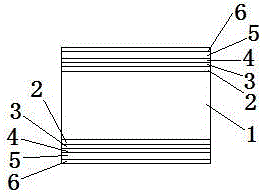

[0057] as attached figure 1 Shown: a sealing gasket for refrigeration equipment, the sealing gasket is a multi-layer composite structure, the multi-layer composite structure includes a natural rubber layer 1, the front and back of the natural rubber layer 1 are sequentially from the inside to the outside An expansion buffer layer 2, a flame-retardant layer 3, an anti-corrosion layer 4, and a cold-resistant layer 5 are provided respectively, and a polytetrafluoroethylene layer 6 is arranged on the outside of the cold-resistant layer 5.

[0058] The expansion buffer layer 2 is a PE / SBS composite layer, and the thickness of the expansion buffer layer 2 is 0.2mm;

[0059] The flame retardant layer 3 is an EVA resin layer, and the thickness of the flame retardant layer 3 is 0.2mm;

[0060] The anti-corrosion layer 4 is a polyphenylene sulfide layer, and the thickness of the anti-corrosion layer 4 is 0.3mm;

[0061] The cold-resistant layer 5 is a carbon fiber layer, and the thick...

Embodiment 2

[0092] as attached figure 1 Shown: a sealing gasket for refrigeration equipment, the sealing gasket is a multi-layer composite structure, the multi-layer composite structure includes a natural rubber layer 1, the front and back of the natural rubber layer 1 are sequentially from the inside to the outside An expansion buffer layer 2, a flame-retardant layer 3, an anti-corrosion layer 4, and a cold-resistant layer 5 are provided respectively, and a polytetrafluoroethylene layer 6 is arranged on the outside of the cold-resistant layer 5.

[0093] The expansion buffer layer 2 is a PE / SBS composite layer, and the thickness of the expansion buffer layer 2 is 0.3mm;

[0094] The flame retardant layer 3 is an EVA resin layer, and the thickness of the flame retardant layer 3 is 0.25mm;

[0095] The anti-corrosion layer 4 is a polyphenylene sulfide layer, and the thickness of the anti-corrosion layer 4 is 0.35mm;

[0096] The cold-resistant layer 5 is a carbon fiber layer, and the thi...

Embodiment 3

[0127] as attached figure 1 Shown: a sealing gasket for refrigeration equipment, the sealing gasket is a multi-layer composite structure, the multi-layer composite structure includes a natural rubber layer 1, the front and back of the natural rubber layer 1 are sequentially from the inside to the outside An expansion buffer layer 2, a flame-retardant layer 3, an anti-corrosion layer 4, and a cold-resistant layer 5 are provided respectively, and a polytetrafluoroethylene layer 6 is arranged on the outside of the cold-resistant layer 5.

[0128] The expansion buffer layer 2 is a PE / SBS composite layer, and the thickness of the expansion buffer layer 2 is 0.4mm;

[0129] The flame retardant layer 3 is an EVA resin layer, and the thickness of the flame retardant layer 3 is 0.3mm;

[0130] The anti-corrosion layer 4 is a polyphenylene sulfide layer, and the thickness of the anti-corrosion layer 4 is 0.4mm;

[0131] The cold-resistant layer 5 is a carbon fiber layer, and the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com