wear bushing

A wear-resistant lining and bushing technology, which is applied in the field of mechanical parts, can solve problems such as uneven distribution, insufficient oil supply, and poor sealing performance, and achieve the effects of uniform distribution of oil passages, uniform oil supply, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

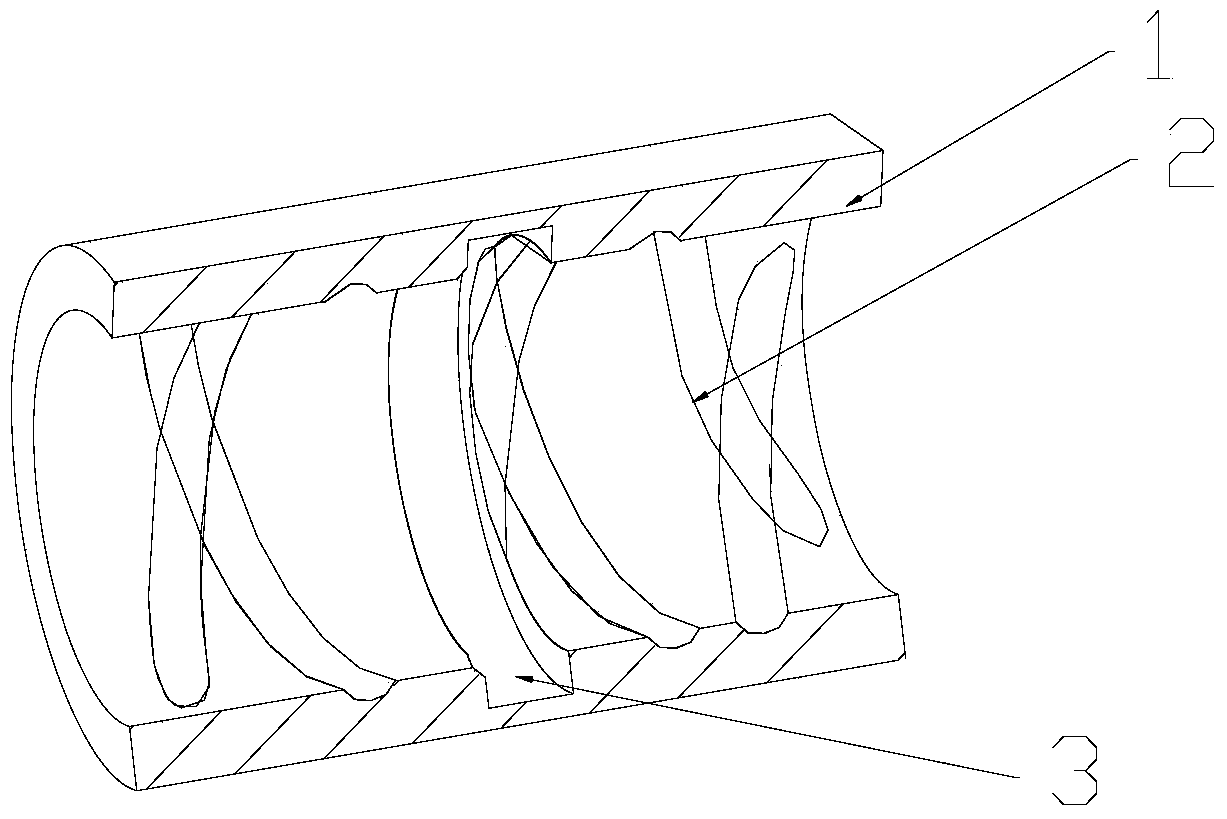

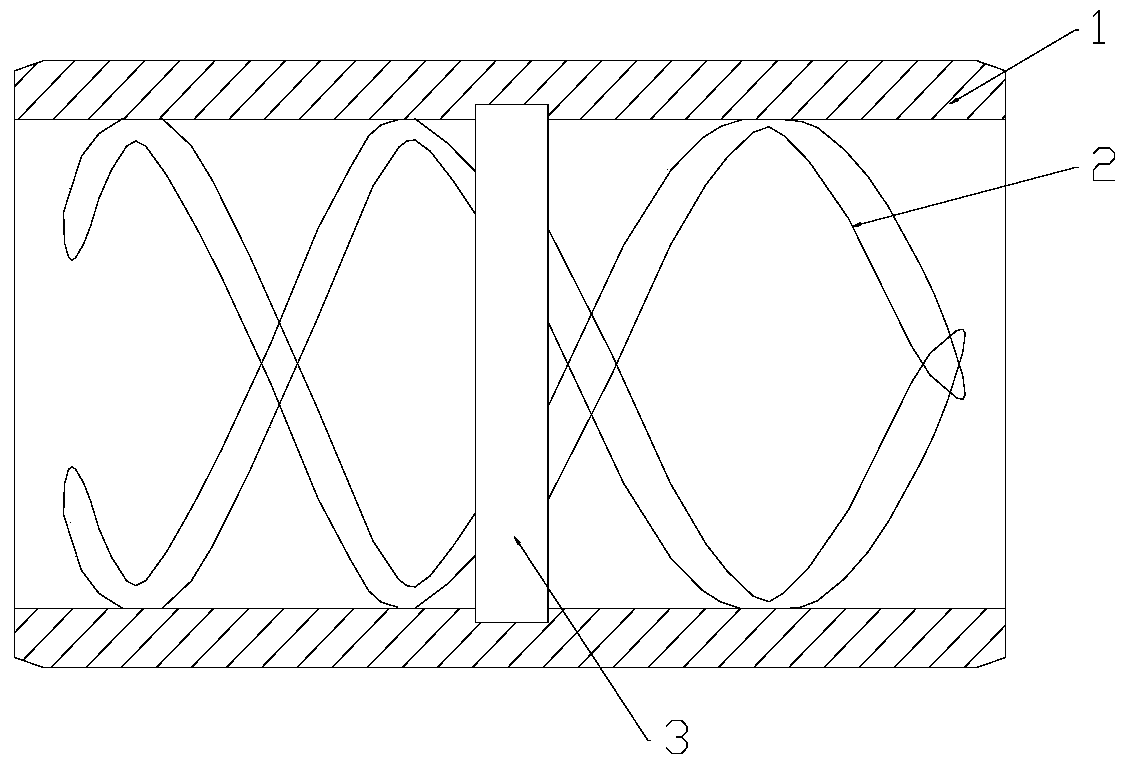

[0047] Such as figure 1 and figure 2 As shown, this embodiment provides a wear-resistant bushing, which includes a bushing main body 1, and the inner wall of the bushing main body 1 is provided with two helically extending lubricating oil passages 2 . The starting ends of the two lubricating oil passages 2 are evenly arranged along the circumference of the bushing body 1 , that is, the starting ends of the two lubricating oil passages are spaced 180 degrees apart. The pitches of the two lubricating oil passages 2 are respectively equal; the two lubricating oil passages 2 cross each other; the beginning and the end of the two lubricating oil passages 2 are respectively closed; the bushing body 1 is also provided with There is an annular oil storage passage 3, the rotation axis of the oil storage passage 3 is in line with the rotation axis of the bushing main body 1; the oil storage passage 3 communicates with the two lubricating oil passages 2 respectively.

[0048] The wear...

Embodiment 2

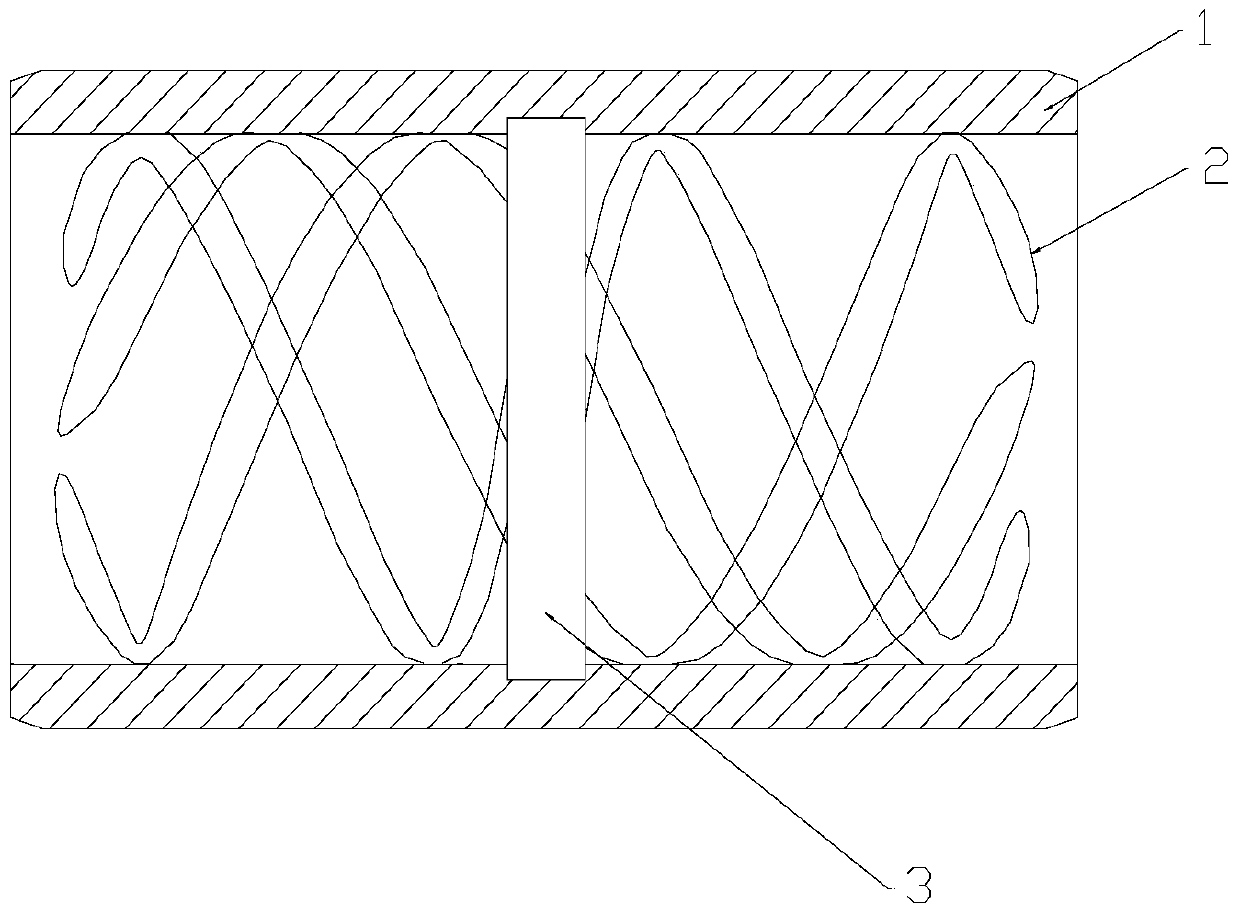

[0057] Such as image 3 As shown, this embodiment provides a wear-resistant bushing, which includes a bushing main body 1, and the inner wall of the bushing main body 1 is provided with three lubricating oil passages 2 extending in a helical shape. The starting ends of the three lubricating oil passages 2 are uniformly arranged along the circumference of the bushing, that is, the starting ends of the three lubricating oil passages are spaced at 180 degrees. The pitches of the three lubricating oil passages 2 are respectively equal; the three lubricating oil passages 2 cross each other; the beginning and the end of the three lubricating oil passages 2 are respectively closed; the bushing main body 1 is also provided with an annular reservoir An oil passage 3, the rotation axis of the oil storage passage 3 is in line with the rotation axis of the bushing; the oil storage passage 3 communicates with the three lubricating oil passages 2 respectively.

[0058] The wear-resistant b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com