Single-screw boosting water injection pump

A single-screw pump and injection pump technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of unstable operation, frequent maintenance, high energy consumption, etc. The effect of injecting benefits and increasing the amount of water injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

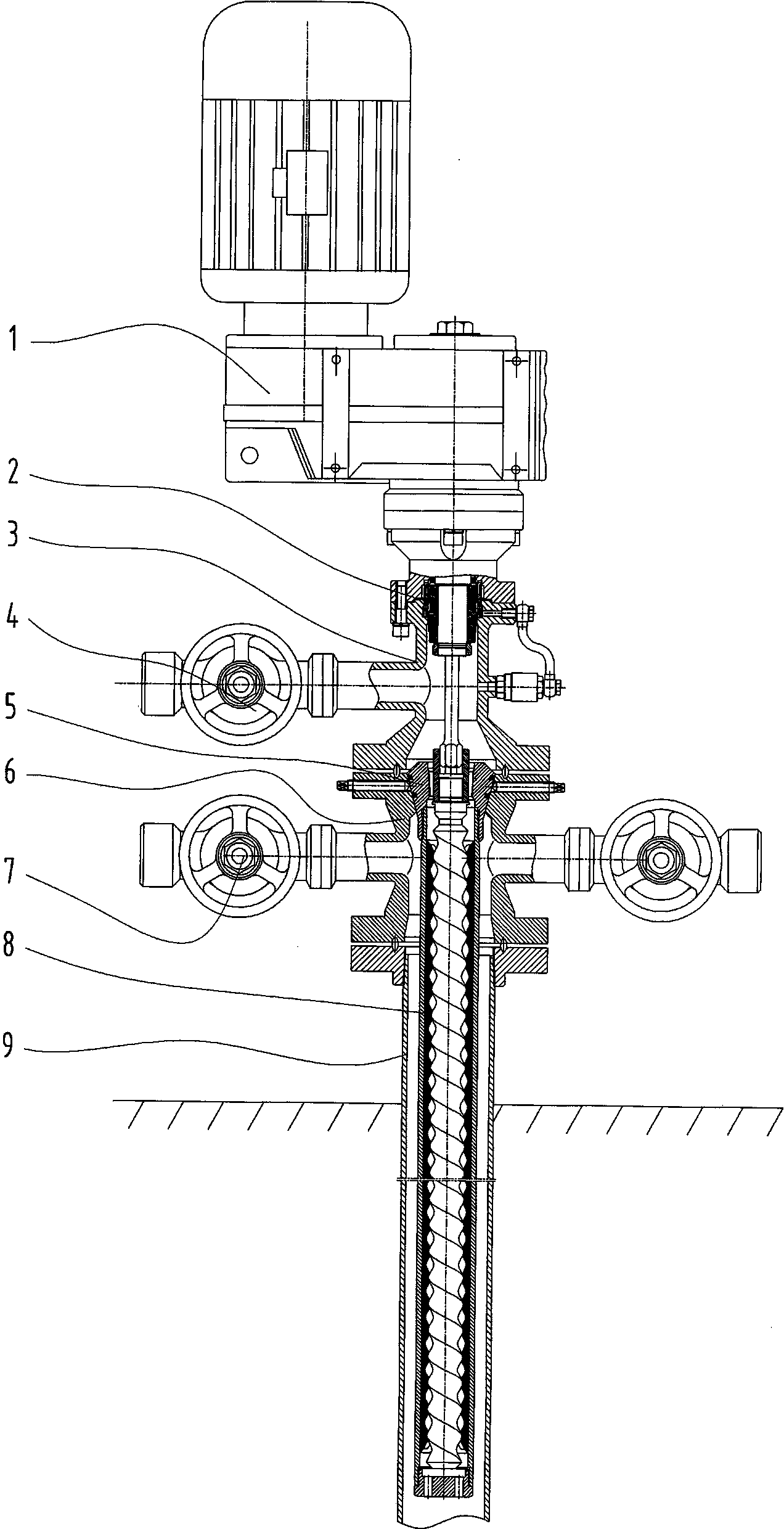

[0007] Depend on figure 1 It can be seen that the embodiment of the present invention includes a rotary power device 1, a mechanical seal device 2, a tee 3, a water inlet valve 4, a hanger 5, a cross 6, a casing valve 7, a single screw pump 8, a casing 9, and four The lower part of the pass 6 is connected to the upper part of the casing 9, the hanger 5 is seated on the upper end hole of the cross 6, the contact between the hanger 5 and the cross 6 is kept sealed, and the single screw pump is connected under the hanger 5 8, the stator of the single screw pump 8 is in the casing 9, the casing valve 7 is installed on the side port of the four-way 6, two casing valves 7 are generally symmetrically installed, and the three-way 3 is installed on the upper end of the four-way 6, The water inlet valve 4 is installed on the side port of the tee 3, and the mechanical seal device 2 is installed in the upper part of the tee 3. The mechanical seal device 2 is a series mechanical seal devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com