Large water hole bypass valve for screw drill

A water hole bypass, screw drilling tool technology, applied in earth-moving drilling, flushing wellbore, wellbore/well components, etc. Improved, simple structure, reduced loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

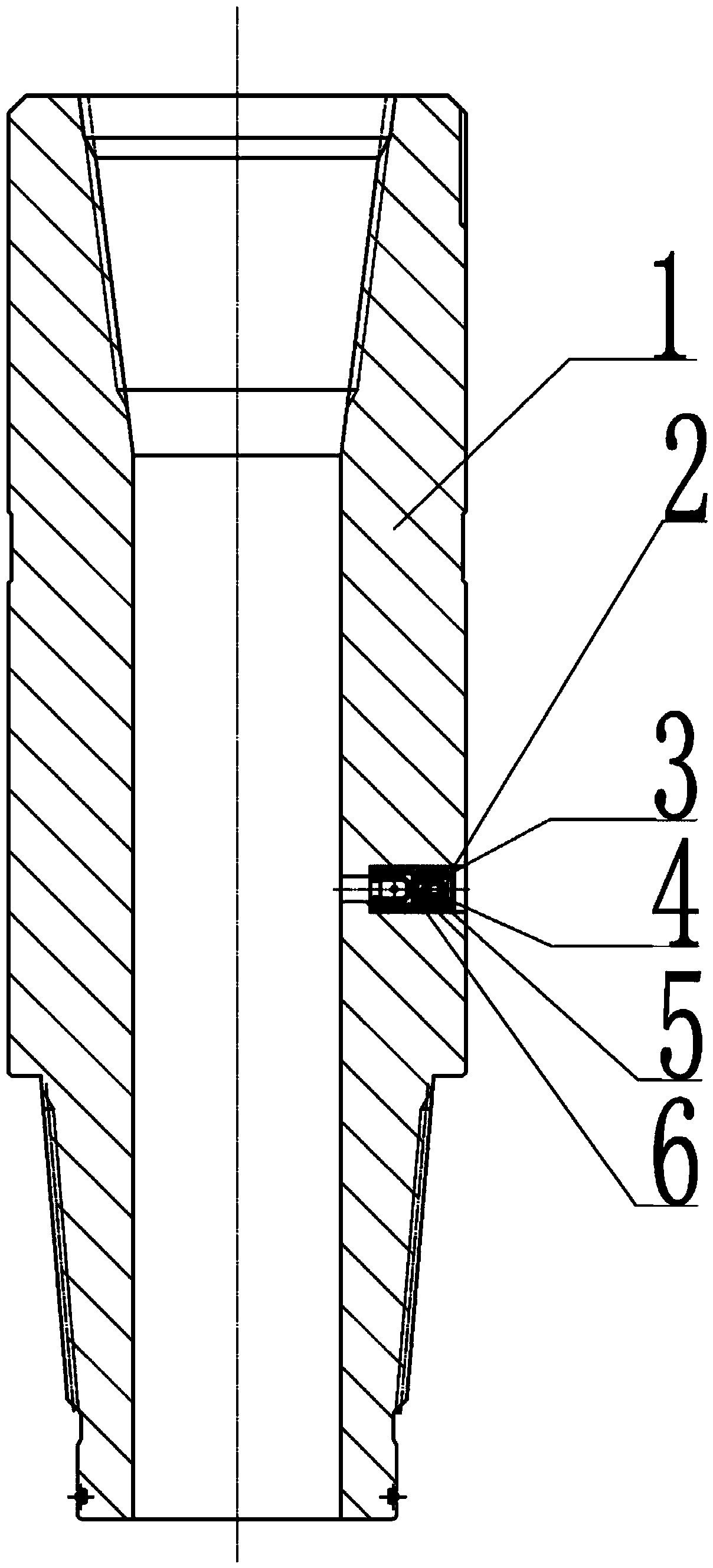

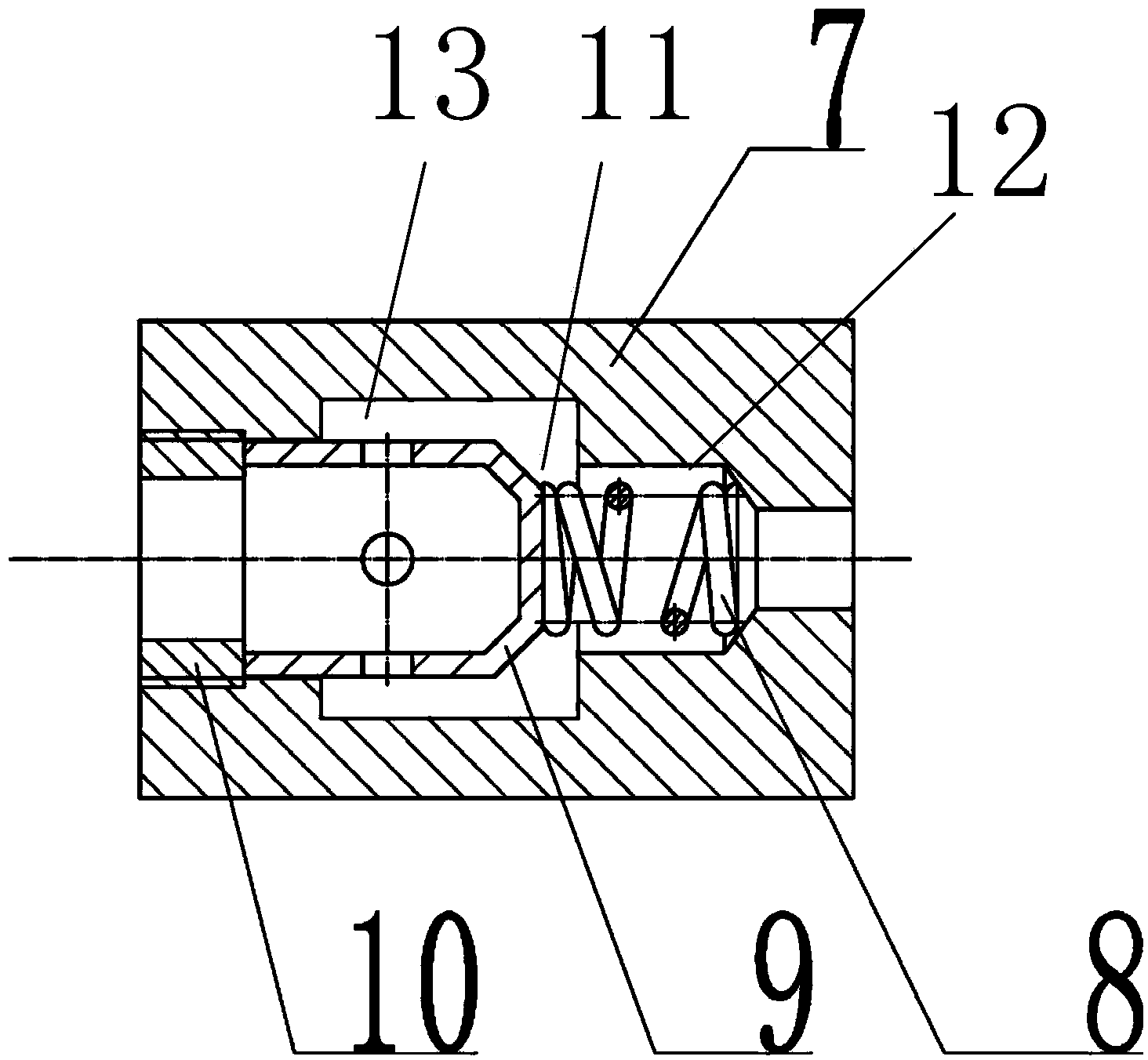

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with accompanying drawing and preferred embodiment, as figure 1 As shown, a large water eye bypass valve for screw drilling tools includes a bypass valve body 1, and a circlip 2, a partition 3, and a screen installed in the bypass hole of the bypass valve body in sequence. plate 4, partition 5, and a one-way valve 6 is also installed in the bypass hole, such as figure 2 As shown, the one-way valve 6 is mainly composed of a one-way valve body 7, a spring 8, a valve core 9 and an inner hexagonal nut 10. The one-way valve body is provided with a stepped inner hole 11, and the spring is placed In the small hole 12 in the stepped inner hole of the one-way valve body, one end of the spring is connected to the top end of the valve core, and the valve core is placed in the large hole in the stepped inner hole of the one-way valve body. In the hole 13, the end of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com