Papain crude enzyme preparation and preparation method thereof

A protease crude enzyme and papain technology, which is applied in the field of papain crude enzyme preparation and its preparation, can solve the problems of difficult increase of production capacity, high price, time-consuming and the like, and achieves a product with good product quality, high recovery rate and less equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 1g of zinc acetate, 5g of vitamin C, and 1g of sodium sulfite to 993g of fresh papaya pulp collected on the same day, and stir (100r / min) at room temperature (26°C) for 15 minutes until all the added enzyme activity protectors are dissolved. Adjust the pH to 5.5 with citric acid solution (2 mol / L), dry at 50°C to obtain small particles of papain, and pulverize it to obtain an enzyme powder preparation with an enzyme activity of 1.02 million units / g.

[0022] Control experiment: add 1g of sodium sulfite to 999g of fresh papaya pulp collected on the same day, stir (100r / min) for 15 minutes at room temperature (26°C), wait for all the added sodium sulfite to dissolve, adjust with citric acid solution (2mol / L) When the pH is 5.5, it is dried at 50°C to obtain small particles of papain, which are pulverized to obtain an enzyme powder preparation with an enzyme activity of 760,000 units / g.

Embodiment 2

[0024] Add 1.2g of zinc acetate, 6g of vitamin C, and 1g of sodium sulfite to 991.8g of fresh papaya pulp collected on the same day, and stir (100r / min) at room temperature (28°C) for 20 minutes until all the added enzyme activity protection agents are dissolved , adjust the pH to 5.8 with citric acid solution (2mol / L), and dry at 55°C to obtain small particles of papain, which are pulverized to obtain an enzyme powder preparation with an enzyme activity of 980,000 units / g.

[0025] Control experiment: Add 1g of sodium bisulfite to 999g of fresh papaya pulp collected on the same day, stir (100r / min) at room temperature (28°C) for 20 minutes, wait until all the added sodium bisulfite is dissolved, and use citric acid solution (2mol / L) to adjust the pH to 5.8, and dry at 55°C to obtain small particles of papain, which are pulverized to obtain an enzyme powder preparation with an enzyme activity of 700,000 units / gram.

Embodiment 3

[0027] Add 1.5g of zinc acetate, 6g of vitamin C, and 1g of sodium sulfite to 998.2g of fresh papaya pulp collected on the same day, and stir (100r / min) at room temperature (26°C) for 20 minutes until all the enzyme activity protection agents added are dissolved. , use citric acid solution (2mol / L) to adjust the pH to 6.0, dry at 52°C to obtain small particles of papain, and after crushing, obtain an enzyme powder preparation with an enzyme activity of 990,000 units / g.

[0028] Control experiment: Add 1g of sodium sulfite to 999g of fresh papaya pulp collected on the same day, stir (100r / min) for 20 minutes at room temperature (26°C), until all the added sodium sulfite is dissolved, adjust with citric acid solution (2mol / L) When the pH reaches 6.0, dry at 52°C to obtain small particles of papain, which are pulverized to obtain an enzyme powder preparation with an enzyme activity of 750,000 units / g.

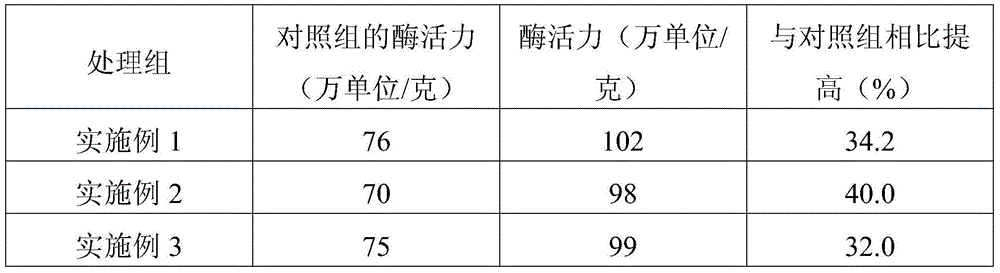

[0029] This method of table 1 prepares the enzyme activity of papain preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com