A kind of non-yellowing polyurethane resin for mirror surface synthetic leather and preparation method thereof

A polyurethane resin and non-yellowing technology, which is applied in the field of non-yellowing polyurethane resin for mirror synthetic leather and its preparation, can solve the problem of reducing product production stability and quality, weak intermolecular force of non-yellowing polyurethane resin, and low temperature resistance. Reduce the risk of insoluble particles and local gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

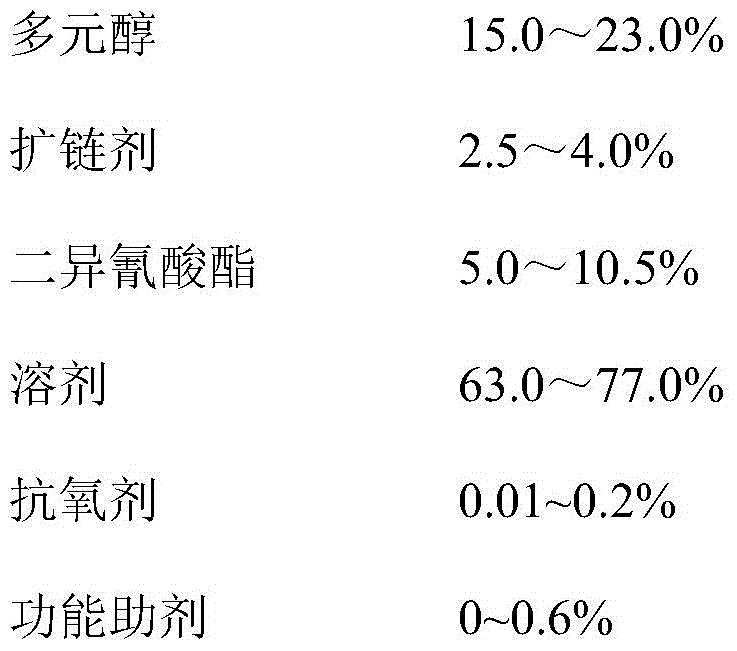

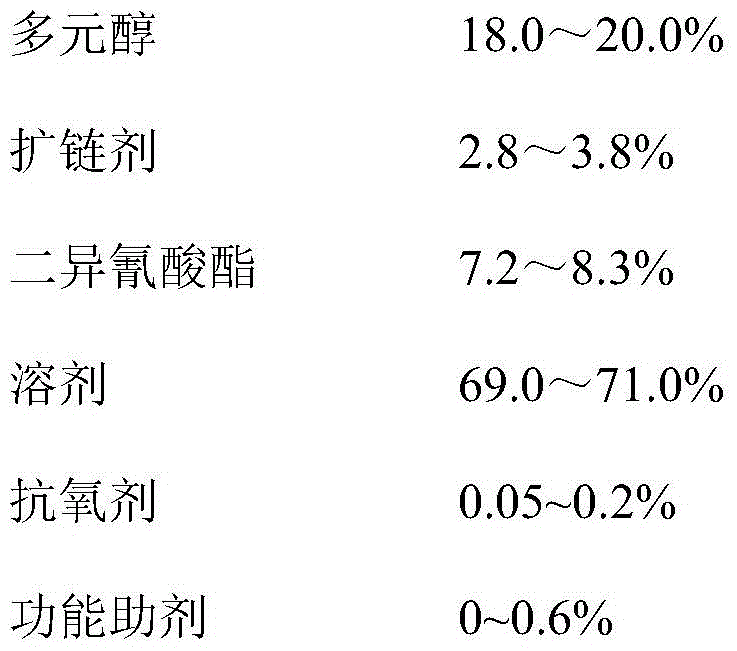

Method used

Image

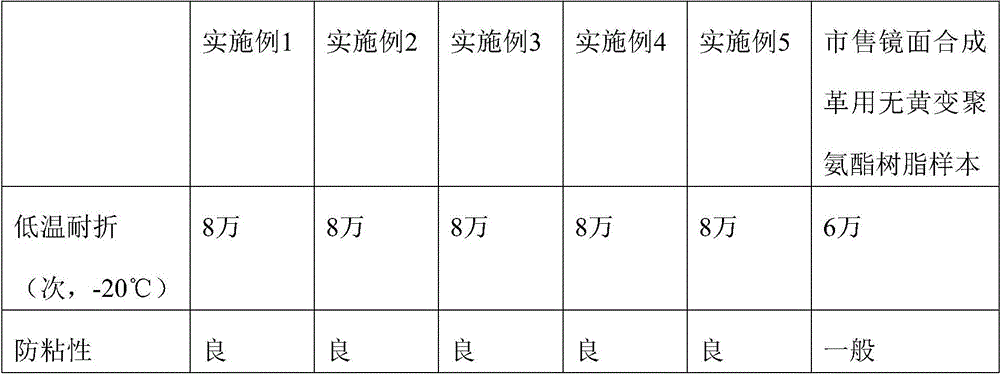

Examples

Embodiment 1

[0039] The raw materials used in this embodiment and their weight are shown in Table 1 below.

[0040] Table 1

[0041] raw material name weight / gram) percentage(%) Antioxidant BHT 0.51 0.02 Polytetrahydrofuran ether glycol (number average molecular weight 2000) 144 5.65 Polytetrahydrofuran ether glycol (number average molecular weight 3000) 216 8.47 Polyneopentyl glycol adipate diol (number average molecular weight 2000) 48 1.88 Ethylene glycol 6.4 0.25 Piperazine 5.31 0.21 4,4'-Diaminodicyclohexylmethane 52 2.04 Isophorone diisocyanate 129 5.06

[0042] dimethylformamide 1109.25 43.50 toluene 369.75 14.50 Isopropanol 469.8 18.42 total weight 2550.02 100%

[0043] The preparation steps of non-yellowing polyurethane resin for the mirror surface synthetic leather of the present embodiment are as follows:

[0044] 1), the polytetrahydrofuran ether glycol of 221.85g di...

Embodiment 2

[0049] The raw materials used in this embodiment and their weight are shown in Table 2 below.

[0050] Table 2

[0051] raw material name weight / gram) percentage(%) Antioxidant BHT 2.4 0.10 Polytetrahydrofuran ether glycol (number average molecular weight 2000) 192 8.00 Polytetrahydrofuran ether glycol (number average molecular weight 3000) 288 12.00 Polybutylene adipate diol (number average molecular weight 2000) 48 2.00 Ethylene glycol 11.23 0.47

[0052] Piperazine 46.73 1.95 4,4'-Diaminodicyclohexylmethane 38.04 1.58 Isophorone diisocyanate 248.75 10.36 dimethylformamide 1240 51.67 toluene 175.4 7.30 Isopropanol 100 4.17 leveling agent 9.6 0.40 total weight 2400.15 100

[0053] Wherein, the chemical name of the leveling agent is polyether-modified dimethyl polysiloxane, and BYK-L9565 of BYK Company is used.

[0054] The preparation steps of non-yellowing ...

Embodiment 3

[0060]The raw materials used in this embodiment and their weight are shown in Table 3 below.

[0061] table 3

[0062] raw material name weight / gram) percentage(%) Antioxidant BHT 0.41 0.02 Polytetrahydrofuran ether glycol (number average molecular weight 2000) 144 7.06 Polytetrahydrofuran ether glycol (number average molecular weight 3000) 216 10.59 Polyneopentyl glycol adipate diol (number average molecular weight 2000) 48 2.35 Ethylene glycol 7.82 0.38 Piperazine 6.51 0.32 4,4'-Diaminodicyclohexylmethane 63.62 3.12 Isophorone diisocyanate 146.39 7.18 dimethylformamide 914.85 44.84 toluene 281.49 13.80 Isopropanol 211.12 10.34 total weight 2040.21 100

[0063] The preparation steps of non-yellowing polyurethane resin for the mirror surface synthetic leather of the present embodiment are as follows:

[0064] 1), the polytetrahydrofuran ether glycol of 182.97g dimethylformami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com