High-magnetic-permeability manganese-zinc series ferrite and preparation method thereof

A high-permeability, ferrite technology, applied in the field of high-permeability manganese-zinc ferrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

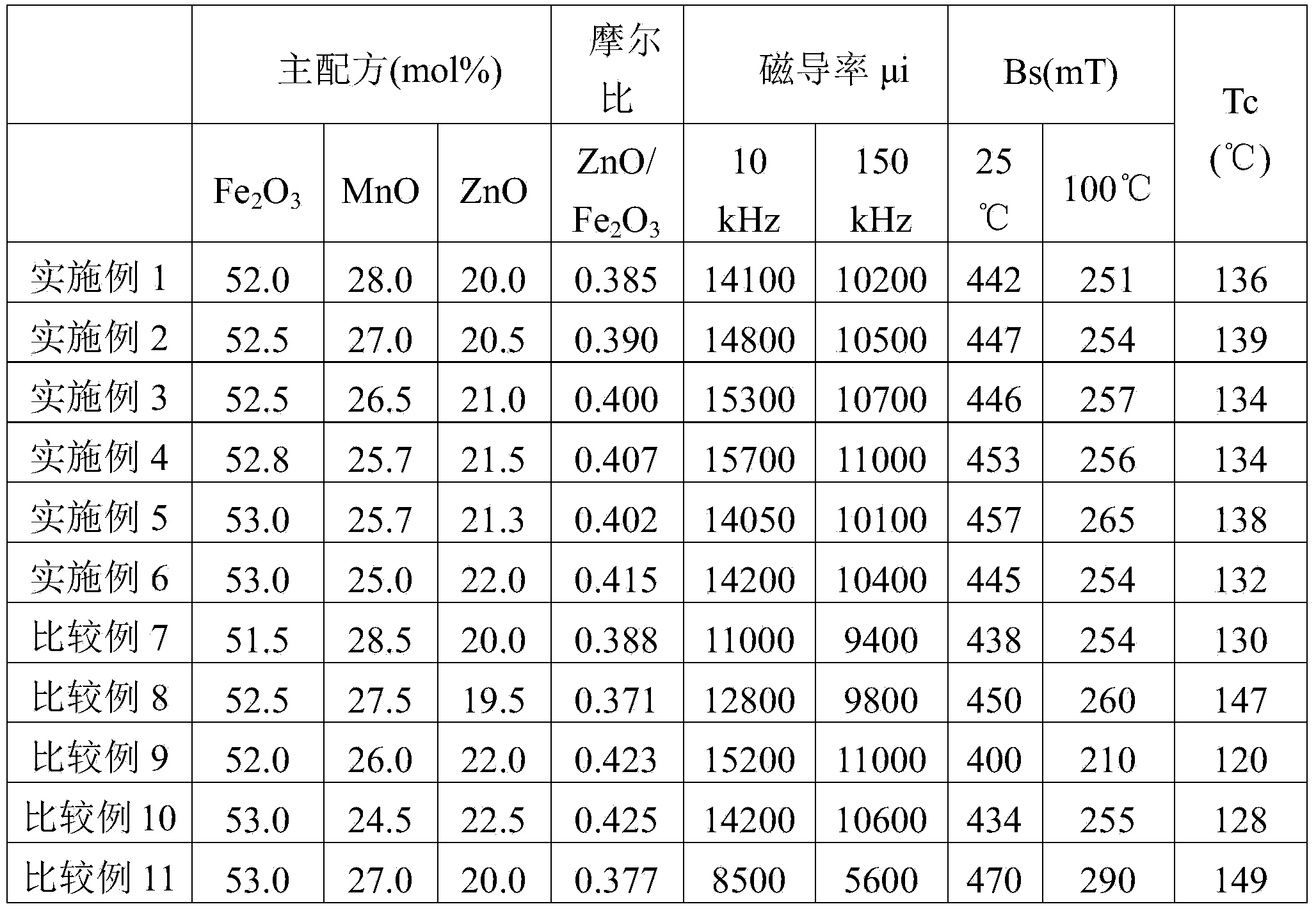

Embodiment 1~11

[0061] A preparation method of manganese-zinc ferrite (Ф25×Ф15×10 manganese-zinc R15k product), specifically comprising the following steps:

[0062] 1) The main component Fe 2 o 3 , ZnO and MnO were added according to the formula in Table 1, wet mixed for about 30 minutes, and sprayed to obtain primary granules;

[0063] 2) Pre-burning the primary pellets at 700-900°C for 2-3 hours to obtain pre-fired material;

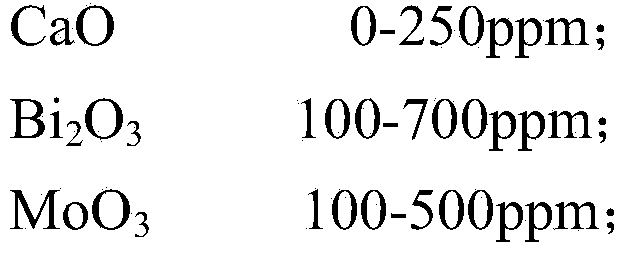

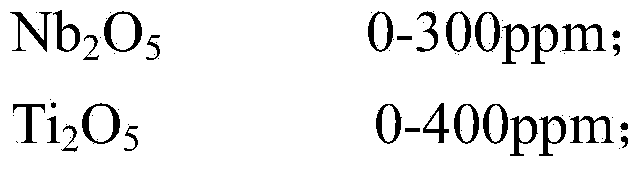

[0064] 3) According to the weight of the main components, add auxiliary components 100ppm CaO, 300ppm Bi to the calcined material 2 o 3 , 200ppm MoO 3 , 200ppm Nb 2 o 5 and 100ppm Ti 2 o 5 , carry out secondary wet sand grinding; control the particle size of the secondary wet grinding slurry to SMD=1.20 μm to obtain ferrite slurry;

[0065] 4) Add 0.5wt% PVA binder, 0.5wt% dispersant 1-methylpentanol and 0.2wt% defoamer silicon oxide to ferrite slurry Spray granulation with alkane; the granulated powder is molded into a blank, and the density of the blank i...

Embodiment 12~21

[0081] Select the main recipe component of embodiment 4: Fe 2 o 3 52.8mol%, ZnO is 26.0mol%, MnO is 21.5mol%, then change the content of auxiliary components according to Table 2, manufacture according to the technique of Example 4, obtain following data through testing:

[0082] Table 2 embodiment 4, the adjuvant formula of 12~21 and test result

[0083]

Embodiment 22~25

[0095] Select the content of the main formula components and auxiliary components of Example 4, then change the secondary wet abrasive particle size SMD according to Table 3, and then manufacture according to the process in Example 4, and obtain the following data after testing: Table 3 Example 4 , 22 to 25 SMD size and test results

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com