Guide trolley of low-rolling-resistance tire cord tearing machine

A technology of low rolling resistance and tire cord, which is applied in the field of tire manufacturing, can solve the problems of low work efficiency, high labor intensity, and hidden safety hazards, and achieve the effect of convenient movement, low labor intensity, and reduced safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

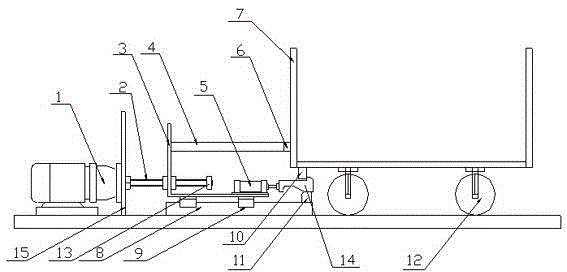

[0013] Such as figure 1 From the schematic diagram shown, it can be known that the unwinding trolley of the low rolling resistance tire cord tearing machine of the present invention includes a deviation correction mechanism, a locking mechanism and a main body 7 of the uncoupling trolley.

[0014] The lower end of the decoupling trolley main body 7 is provided with a movable pulley 12 for the decoupling trolley main body 7. There are four pulleys 12, which are distributed in the lower end of the decoupling trolley main body 7 in a rectangular shape. The side is locked by the locking mechanism, and the main body 7 of the trolley can be driven to reciprocate in the horizontal direction by the deviation correction mechanism.

[0015] The deviation correction mechanism includes a deviation correction motor 1, a deviation correction screw 2, a deviation correction bracket 3, a deviation correction guide rail 8 and a deviation correction guide rail slider 9, and one end of the devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com