A two-link active arm for manufacturing

A movable arm and connecting rod technology, which is applied in the direction of manufacturing tools, claw arms, spraying devices, etc., can solve the problems of high maintenance costs, high cost of mechanical arms, long training period, etc., and achieve easy maintenance, simple structure, and easy maintenance. The effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

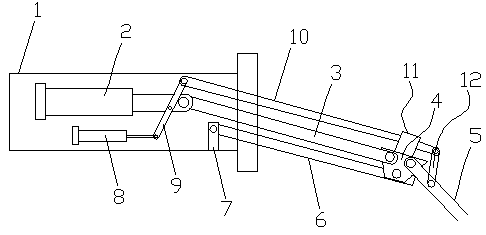

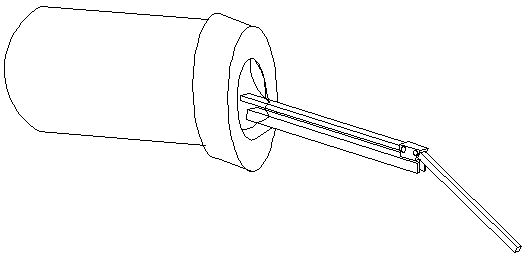

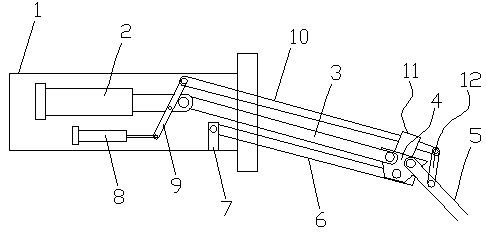

[0022] As shown in the figure: a two-link movable arm for manufacturing, including a casing 1, a master cylinder 2, a driving rod 3, a connecting rod 4, and a driven rod 5; Cylinder 2, the master cylinder 2 is connected with one end of the active rod 3, the other end of the active rod 3 is connected with the connecting rod 4, and one end of the driven rod 5 is connected with the connecting rod 4; the other end of the driven rod 5 A processing device is installed at one end; the master cylinder 2 controls the rise and fall of the active rod 3 and the driven rod 5 .

[0023] The two-link movable arm used for manufacturing also includes a support rod 6 and a hinge rod 7; Connected, the support rod 6 is arranged below the active rod 3, and the support rod 6 and the active rod 3 are parallel to each other.

[0024] The connecting rod part 4 described in the two-link type movable arm is an inverted trapezoid, and the top end of the connecting rod part 4 is provided with two hinged ...

Embodiment 2

[0029] A two-link movable arm for manufacturing, comprising a casing 1, a master cylinder 2, a driving rod 3, a connecting rod 4, and a driven rod 5; the master cylinder 2 is arranged in the casing 1, and the The master cylinder 2 is connected with one end of the active rod 3, the other end of the active rod 3 is connected with the connecting rod 4, and one end of the driven rod 5 is connected with the connecting rod 4; the other end of the driven rod 5 is equipped with a processing device; Master cylinder 2 controls the rise and fall of active rod 3 and driven rod 5 .

[0030] The two-link movable arm used for manufacturing also includes a support rod 6 and a hinge rod 7; Connected, the support rod 6 is arranged below the active rod 3, and the support rod 6 and the active rod 3 are parallel to each other. The connecting rod part 4 described in the two-link type movable arm is an inverted trapezoid, and the top end of the connecting rod part 4 is provided with two hinged shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com