Automatic multilayer abrasive paper blanking device

A technology of automatic blanking and forming equipment, applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of increasing the cost of human resources, asynchronous feeding of multi-layer sandpaper, offset and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

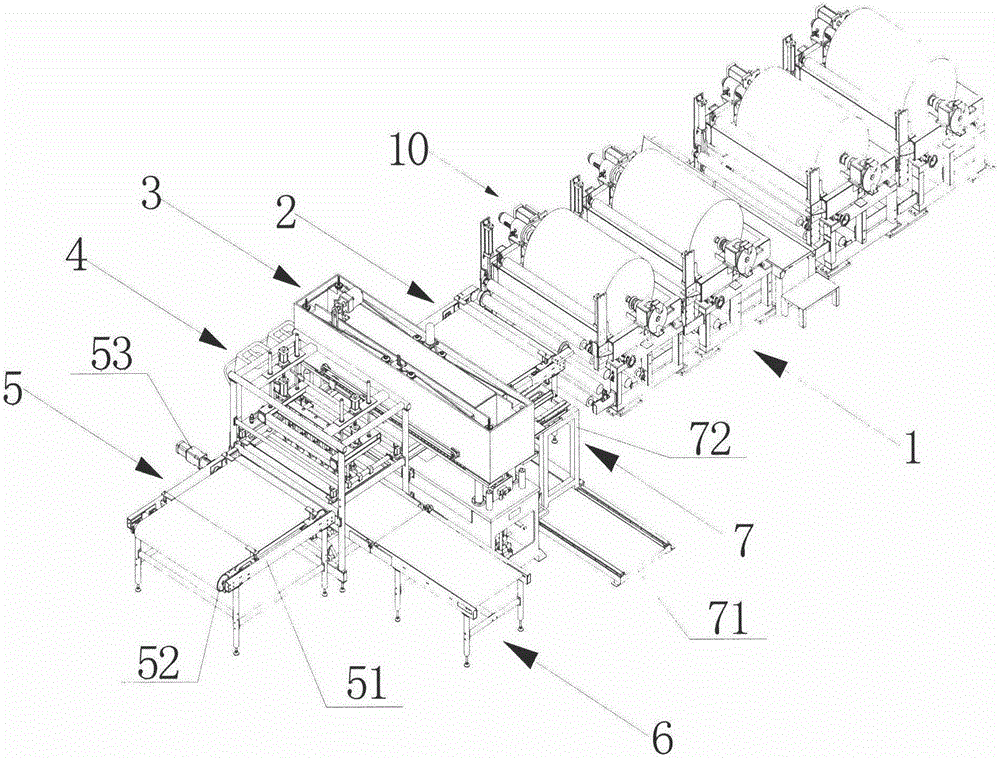

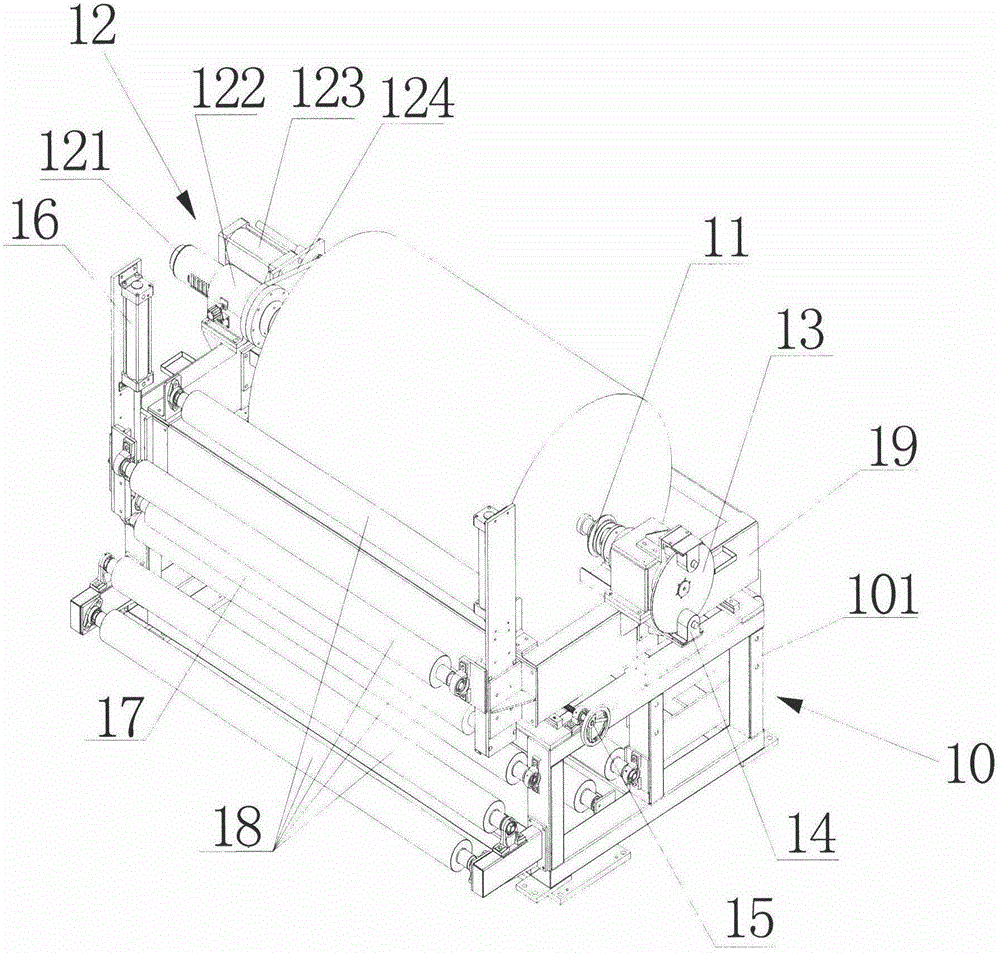

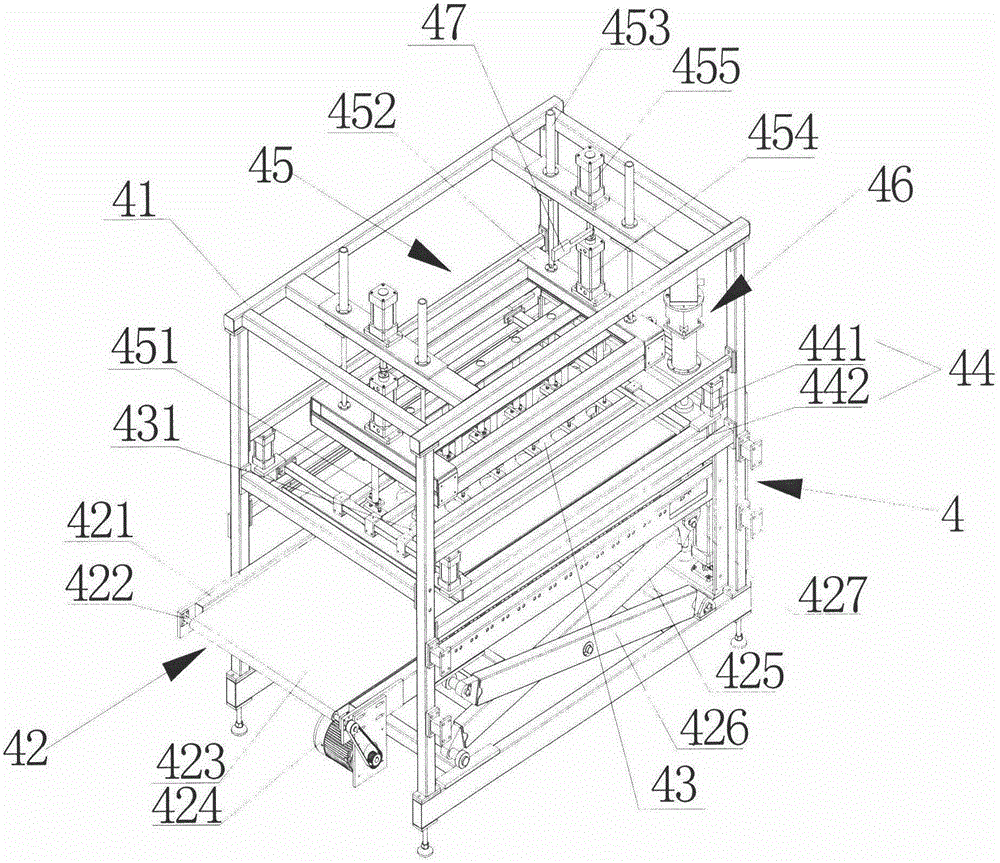

[0021] Such as figure 1 The multi-layer sandpaper automatic punching and forming equipment shown mainly includes a discharging component 1, a feeding component 2, a cutting host 3, a stacking component 4, a waste collecting component 5 and a discharging component 6, wherein the discharging component 1, the feeding component Component 2, cutting host 3, stacking component 4, and waste material collecting component 5 are arranged in sequence. The discharging assembly 6 is arranged beside the stacking assembly 4, and is used for accepting the sandpaper sheets neatly stacked by the stacking assembly 4. The automatic discharging assembly 1 includes a plurality of discharging mechanisms 10 sequentially arranged for storing sandpaper, and there are four discharging mechanisms 10 in this embodiment. The feeding assembly 2 is used for receiving the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com