Flow-controllable continuous sandblasting machine

A technology of sandblasting machine and flow rate, applied in the field of sandblasting machine, can solve the problems of clogging of pipelines and nozzles, and achieve the effect of accurately adjusting the injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

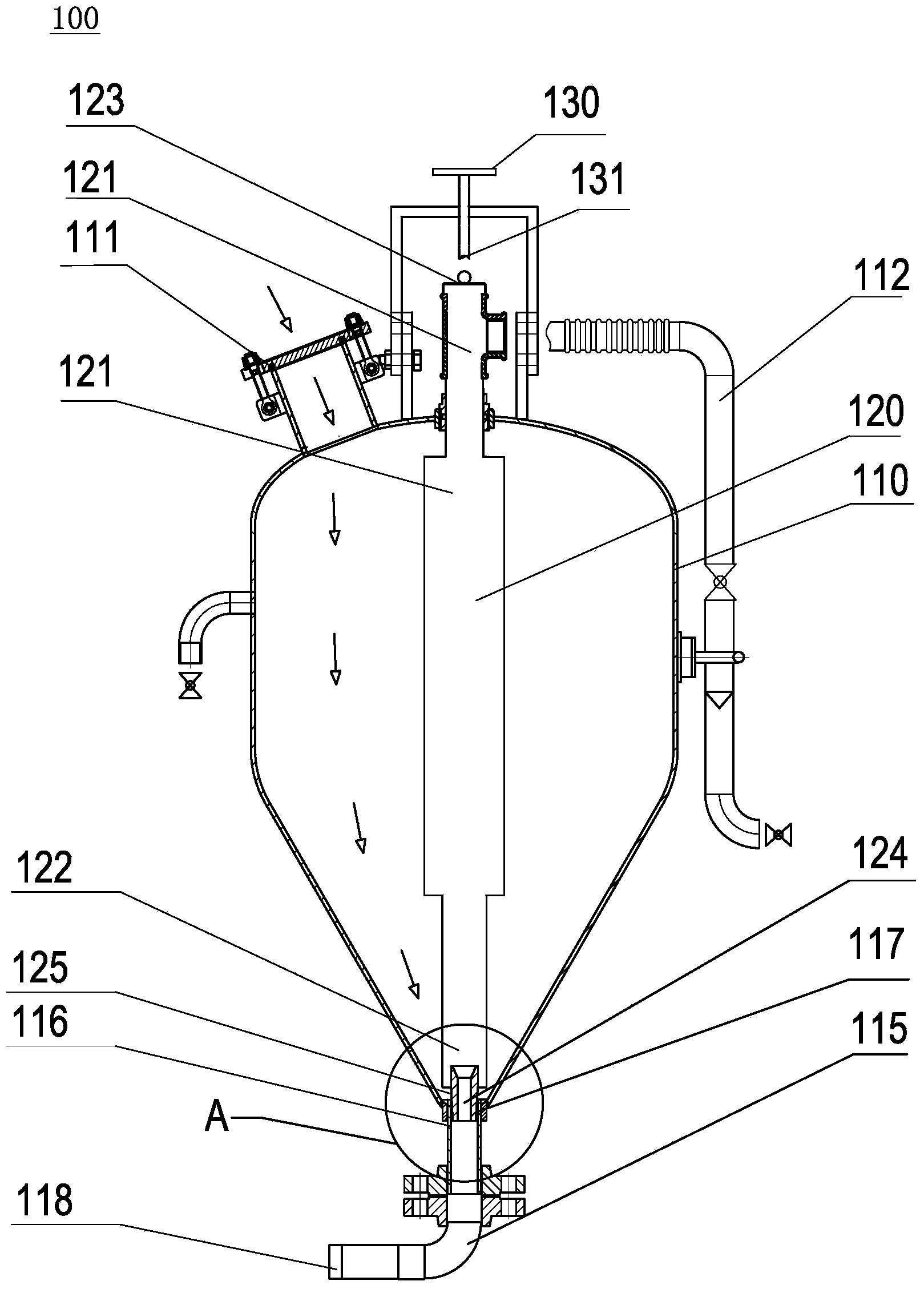

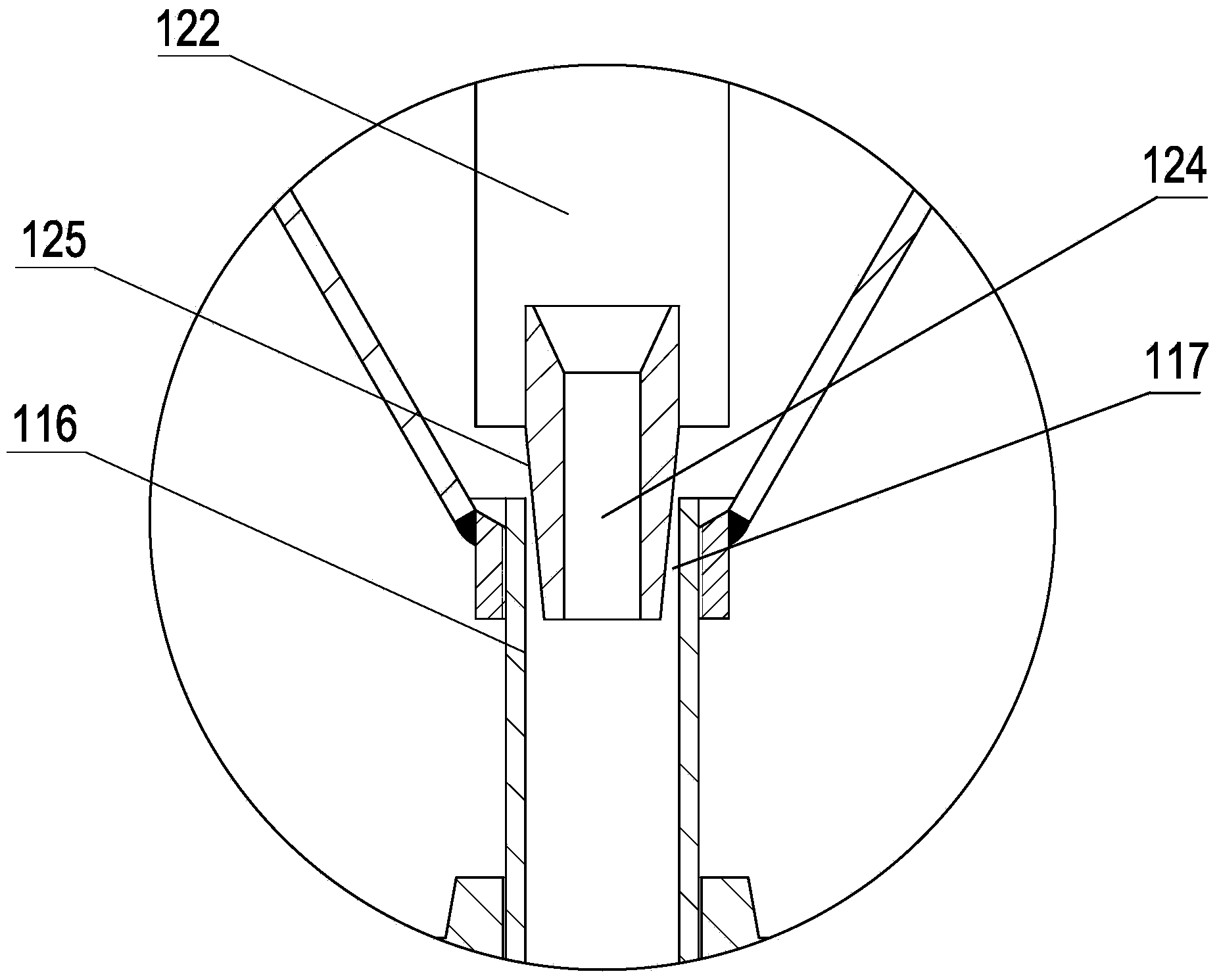

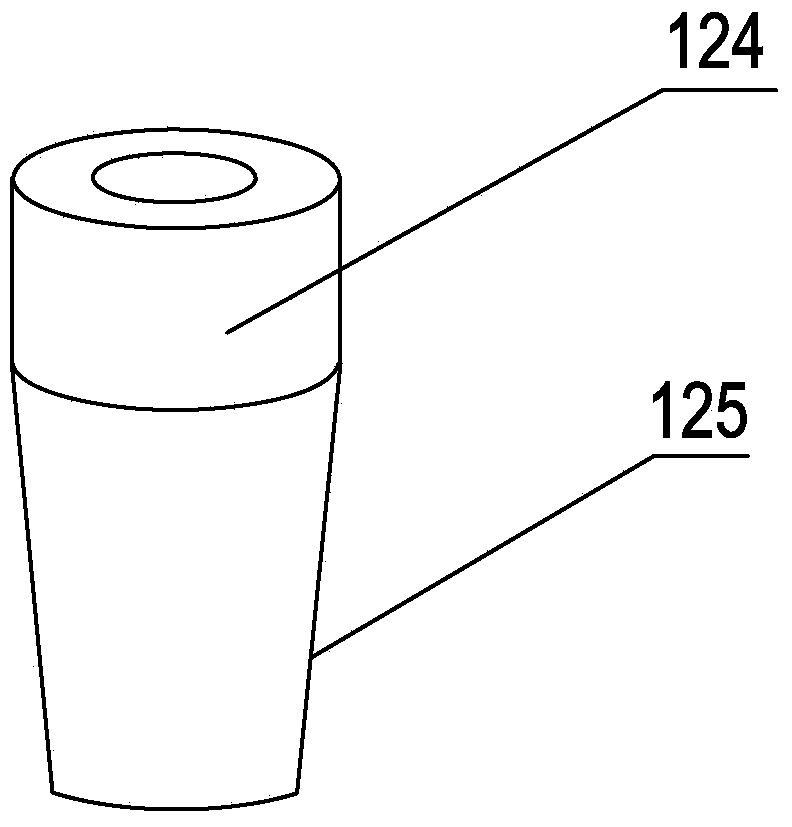

[0025] refer to figure 1 and figure 2 , a flow controllable continuous blasting machine 100, including a material tank 110, a center pipe 120, an adjusting rod 130 and an air compression device (not shown). The upper outer wall of the material tank 110 is provided with a feeding port 111 , and the lower outer wall is provided with an outlet pipe 115 connected to a sandblasting nozzle 118 . The central tube 120 has an upper part 121 , a lower part 122 and a top end 123 , and the lower part 122 is provided with a Venturi nozzle 124 . The upper part 121 of the central tube 120 is movably connected to the material tank 110 , the upper part passes through the top of the material tank 110 and can slide up and down relative to the top of the material tank 110 , and the rest is arranged inside the material tank 110 . The Venturi nozzle 124 protrudes into the outlet pipe 115 . The air compression device is provided with an air inlet pipe 112 , and the air inlet pipe 112 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com