Welding method for box type part of air intake machine

A technology of intake casing and welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of company waste, crack failure, unallowable use or scrapping, etc., to reduce repair costs and improve reliability , the effect of solving production bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A welding method for air intake casing parts is carried out according to the following steps:

[0030] (1) Carry out coloring inspection at the crack;

[0031] (2) Separate the variable camber blade, separate the support plate that needs to be repaired by welding and the fixing nut at the boss of the adjacent support plate;

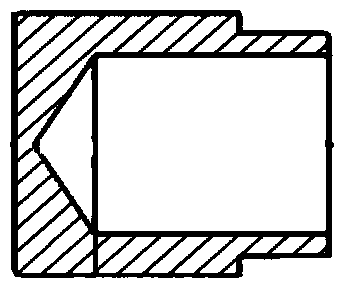

[0032] (3) Process heat-conducting copper sleeves such as figure 2 , image 3 As shown, it is installed on the support of the intake casing, and the assembly gap with the intake casing is guaranteed to be 0.01mm;

[0033] (4) Punch holes at the end of the crack to arrest the crack;

[0034] (5) Rinse with acetone, degrease the cracks and adjacent positions with a width of about 30mm, and dehydrate with ethanol;

[0035] (6) Install the heat-conducting copper blocks of the tool set on the mounting holes of the supports that need to be repaired, and perform argon arc welding on the cracks according to the following regulations:

[0036] Type of ...

Embodiment 2

[0046] A welding method for air intake casing parts is carried out according to the following steps:

[0047] (1) Carry out coloring inspection at the crack;

[0048] (2) Separate the variable camber blade, separate the support plate that needs to be repaired by welding and the fixing nut at the boss of the adjacent support plate;

[0049] (3) Process heat-conducting copper sleeves such as figure 2 , image 3 As shown, it is installed on the support of the intake casing, and the assembly gap with the intake casing is guaranteed to be 0.03mm;

[0050] (4) Punch holes at the end of the crack to arrest the crack;

[0051] (5) Rinse with acetone, degrease the cracks and adjacent positions with a width of about 30mm, and dehydrate with ethanol;

[0052] (6) Install the heat-conducting copper blocks of the tool set on the mounting holes of the supports that need to be repaired, and perform argon arc welding on the cracks according to the following regulations:

[0053] Type of ...

Embodiment 3

[0063] A welding method for air intake casing parts is carried out according to the following steps:

[0064] (1) Carry out coloring inspection at the crack;

[0065] (2) Separate the variable camber blade, separate the support plate that needs to be repaired by welding and the fixing nut at the boss of the adjacent support plate;

[0066] (3) Process heat-conducting copper sleeves such as figure 2 , image 3 As shown, it is installed on the support of the intake casing, and the assembly gap with the intake casing is guaranteed to be 0.02mm;

[0067] (4) Punch holes at the end of the crack to arrest the crack;

[0068] (5) Rinse with acetone, degrease the cracks and adjacent positions with a width of about 30mm, and dehydrate with ethanol;

[0069](6) Install the heat-conducting copper blocks of the tool set on the mounting holes of the supports that need to be repaired, and perform argon arc welding on the cracks according to the following regulations:

[0070] Type of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com