One-stop preparation method of vascularized life structure

A structure and vascularization technology, applied in the direction of prosthesis, medical science, etc., can solve the problem of inability to solve the problem of cell positioning, and achieve the effect of improving the survival rate of implantation, reducing the volume of materials, and promoting integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

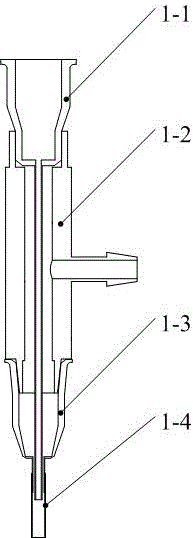

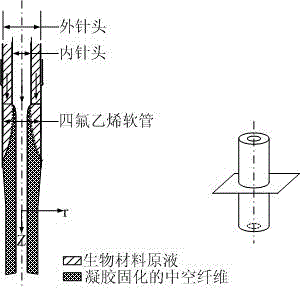

[0030] see Figure 1~Figure 6 , the one-stop preparation method of the vascularized life structure: the preparation system uses the syringe pump (1) to provide the driving force required for material extrusion; two medical piston syringes are used as the two supply syringes (2, 3), One is the core supply syringe (3), the other is the shell supply syringe (2); the inner needle of the coaxial nozzle (4) is connected to the core supply syringe (3), the coaxial nozzle (4 ) is connected to the shell feeding syringe (2); the preparation process is as follows:

[0031] 1) Stock solution preparation: the biological material and its cross-linking agent are prepared in a set ratio with the corresponding solvent to prepare the biological material stock solution and the cross-linking agent stock solution;

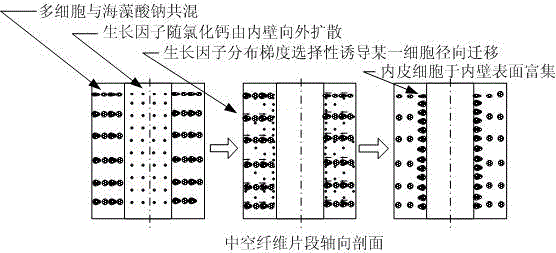

[0032] 2) Mixing of cells and growth factors: add a single cell or multiple cells to the biological material stock solution according to the set concentration, mix well and put it int...

Embodiment 2

[0037]This example is basically the same as Example 1, and the special features are as follows: Step 1) Stock solution preparation: the biological material is mainly composed of sodium alginate, and deionized water is used as a solvent to prepare a concentration of 3-5% (w / v) biological material stock solution; in addition, hydroxyapatite, chitosan or gelatin materials can also be added, and the mass ratio of the added amount to sodium alginate is (0.5~1.5):1 to improve the life structure (6 ) mechanical and biological properties; the cross-linking agent is calcium chloride, and the cross-linking and solidification of the biological material stock solution is realized through the rapid diffusion of calcium ions and the chelation reaction with sodium alginate; the calcium chloride is prepared with deionized water as a solvent Make a cross-linking agent stock solution with a concentration of 3~4% (w / v). The combination of the biological material stock solution and the crosslink...

Embodiment 3

[0042] Example 3: Preparation of Bone Tissue Structure

[0043] In this case, cell manipulation is involved, which needs to be carried out in a sterile environment. Therefore, the experimental equipment and materials should be sterilized before the experiment. The experiment is carried out in an ultra-clean bench. The specific steps are as follows:

[0044] (1) Stock solution preparation: Weigh 2 g each of sodium alginate (Alg) and hydroxyapatite (HA) with an electronic balance, mix the two materials evenly by ball milling, dissolve in 50 ml of deionized water, stir and oscillate until completely dissolved, vacuum After defoaming, let it stand for later use; weigh 3g of calcium chloride, dissolve it in 100ml of deionized water, stir and oscillate until completely dissolved.

[0045] (2) Mixing of cells and growth factors: drop osteoblasts and endothelial cells into the mixed solution of Alg and HA, so that the concentration of both cells is 2×10 6 cells / ml, then fill the cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com