Potato residue no-mucedin fried bread stick and making method thereof

A technology of potato dregs and potato dregs powder is applied in the directions of food preparation, food ingredients as taste improver, food ingredients as anti-microbial preservation, etc. The effect of inner color, uniform moisture absorption, and enhancement of health properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

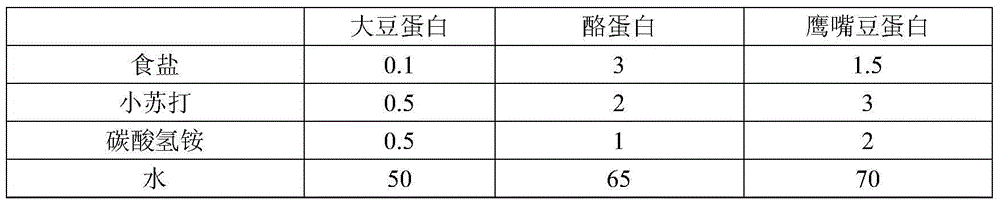

[0038] Embodiment 1: the raw material of potato residue gluten-free fried dough sticks

[0039] The raw materials of the gluten-free fried dough sticks from potato dregs are raw potato dregs powder, superfine potato dregs powder, potato dregs nanopowder, potato modified starch, extruded potato dregs powder, potato dregs microwave-treated powder, potato starch, potato pectin, Sweet potato stem and leaf polyphenols, sweet potato protein, salt, baking soda, ammonium bicarbonate and water, the mass ratio of the above components is 25:21:12:8:10:10:5:1.5:0.7:5:2 :2:2:55.

Embodiment 2

[0040] Embodiment 2: the raw material of potato dregs gluten-free fried dough sticks

[0041] The raw material of the potato dregs gluten-free fritters consists of potato dregs raw powder, potato dregs superfine powder, potato dregs nanopowder, potato modified starch, extruded potato dregs powder, potato dregs microwave-treated powder, potato starch, beet pectin, Tea polyphenols, whey protein isolate, salt, baking soda, ammonium bicarbonate and water are mixed, and the mass ratio of the above ingredients is 25:30:10:8:6:11:2:1.5:0.7:8:3 :3:3:62.

Embodiment 3

[0043] Get the potato dregs gluten-free deep-fried dough stick raw material powder that embodiment 1 obtains, carry out according to the following steps:

[0044] 1) According to 25 parts of potato dregs raw powder, 21 parts of potato dregs superfine powder, 12 parts of potato dregs nano powder, 8 parts of potato modified starch, 10 parts of extruded potato dregs powder, 10 parts of potato dregs microwave treatment powder, and 5 parts of potato starch 1.5 parts of potato pectin, 0.7 parts of sweet potato stem and leaf polyphenols, 5 parts of sweet potato protein, 2 parts of table salt, 2 parts of baking soda, 2 parts of ammonium bicarbonate, and 55 parts of water. Slag superfine powder, potato dregs nano powder, potato modified starch, extruded potato dregs powder, potato dregs microwave processing powder, potato starch, potato pectin, sweet potato stem and leaf polyphenols, sweet potato protein, salt, baking soda, ammonium bicarbonate and water;

[0045] 2) heating the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com