Method and device for measuring passing resistance of supporting rollers of conveyor belt

A technology for supporting rollers and resistance measurement, which is applied to measurement devices, using stable tension/pressure to test the strength of materials, and using mechanical devices to achieve the effect of improving measurement accuracy and simplifying measurement devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] [via resistance]

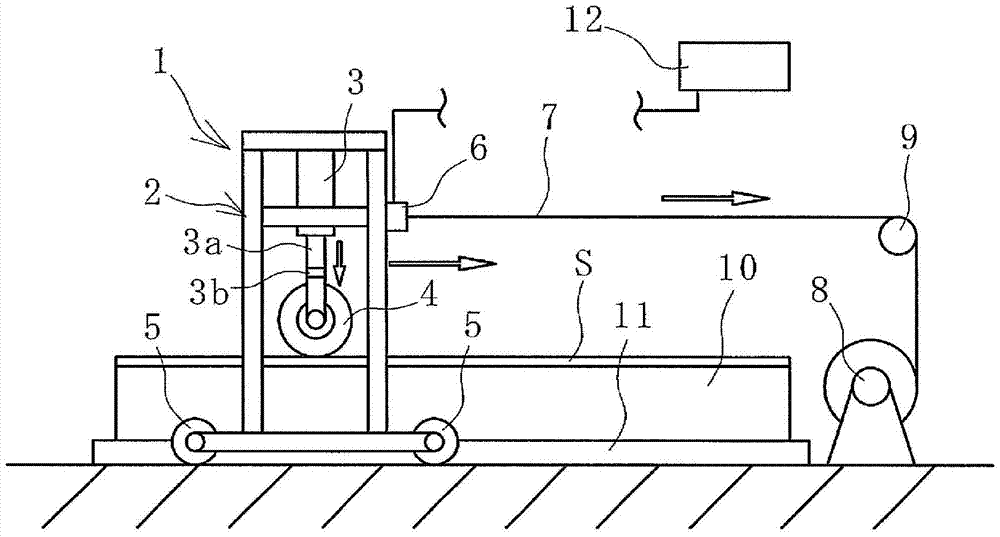

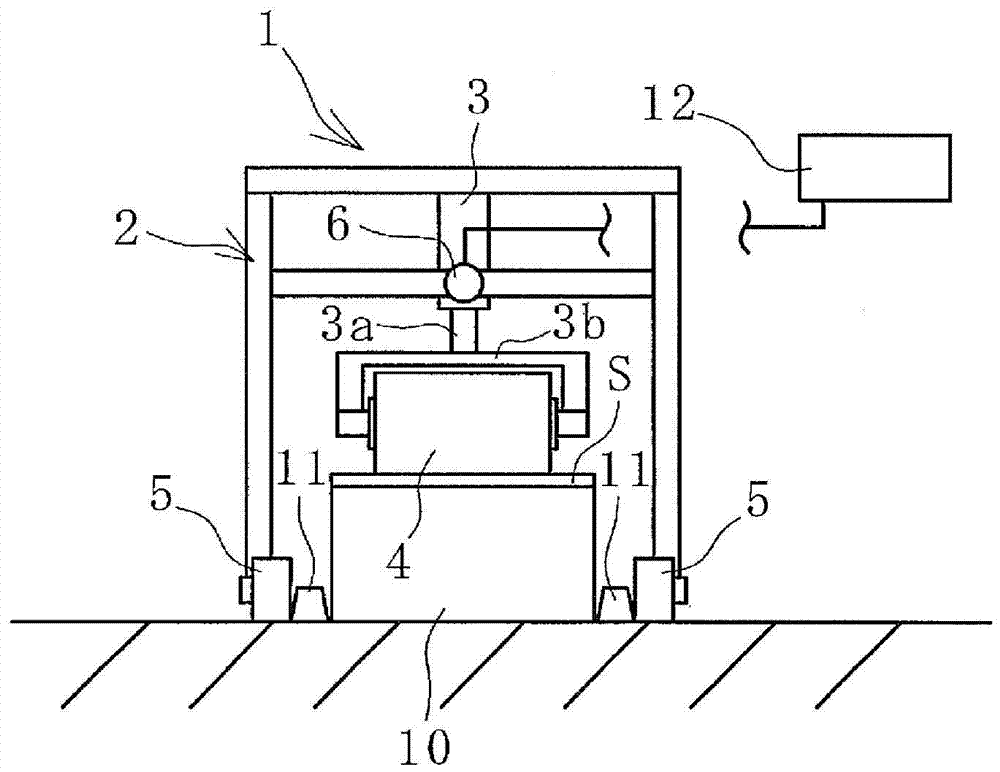

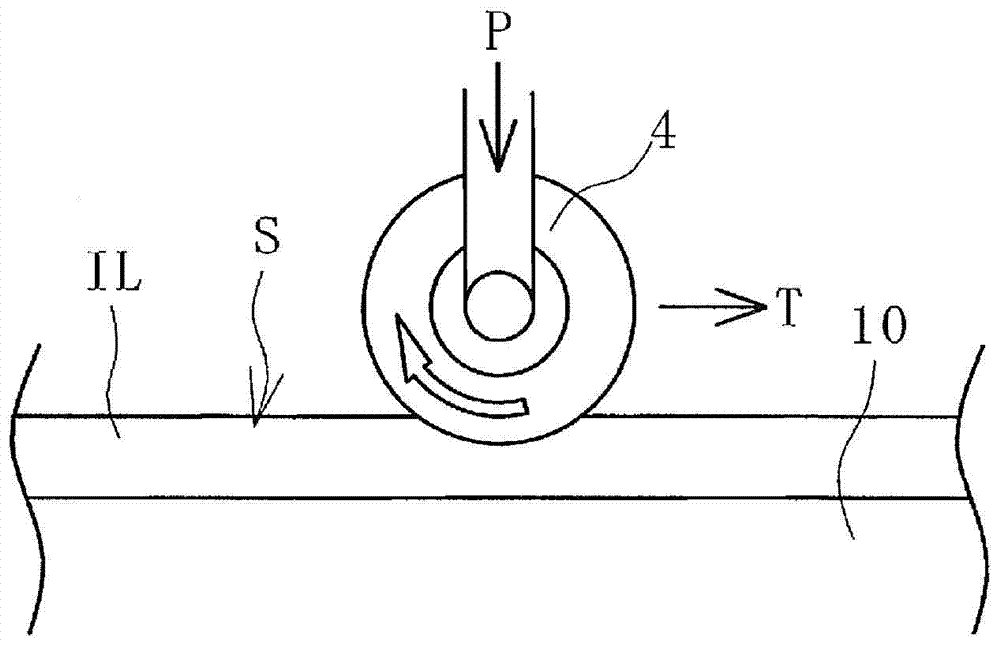

[0048] Use the structure with Figure 1 ~ Figure 3 Using the same measuring device as Measuring Device 1, the tensile force T (support roller passing resistance) was measured for the four evaluation objects (samples 1 to 4) listed in Table 1. The results are as follows Figure 7 shown. The size of each sample was 4000 mm in length, 150 mm in width, and 9 mm in thickness. The moving speed of the supporting roller is 0.92m / s, the outer diameter of the roller is 90mm, and the external force applied vertically downward to the supporting roller is 31N.

[0049] Table 1

[0050]

[0051] according to Figure 7 The results show that the passage resistance of energy-saving samples 2 and 4 is lower than that of general samples 1 and 3, respectively. This result shows that, including the relative magnitude of the passage resistance, the passage resistance can be measured with high accuracy, almost the same as when the support roller passage resistance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com