Vacuum motor

A technology for vacuum motors and motor casings, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., which can solve the problems of long-term stable operation of motors and rising costs, and achieve the effect of reducing temperature and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

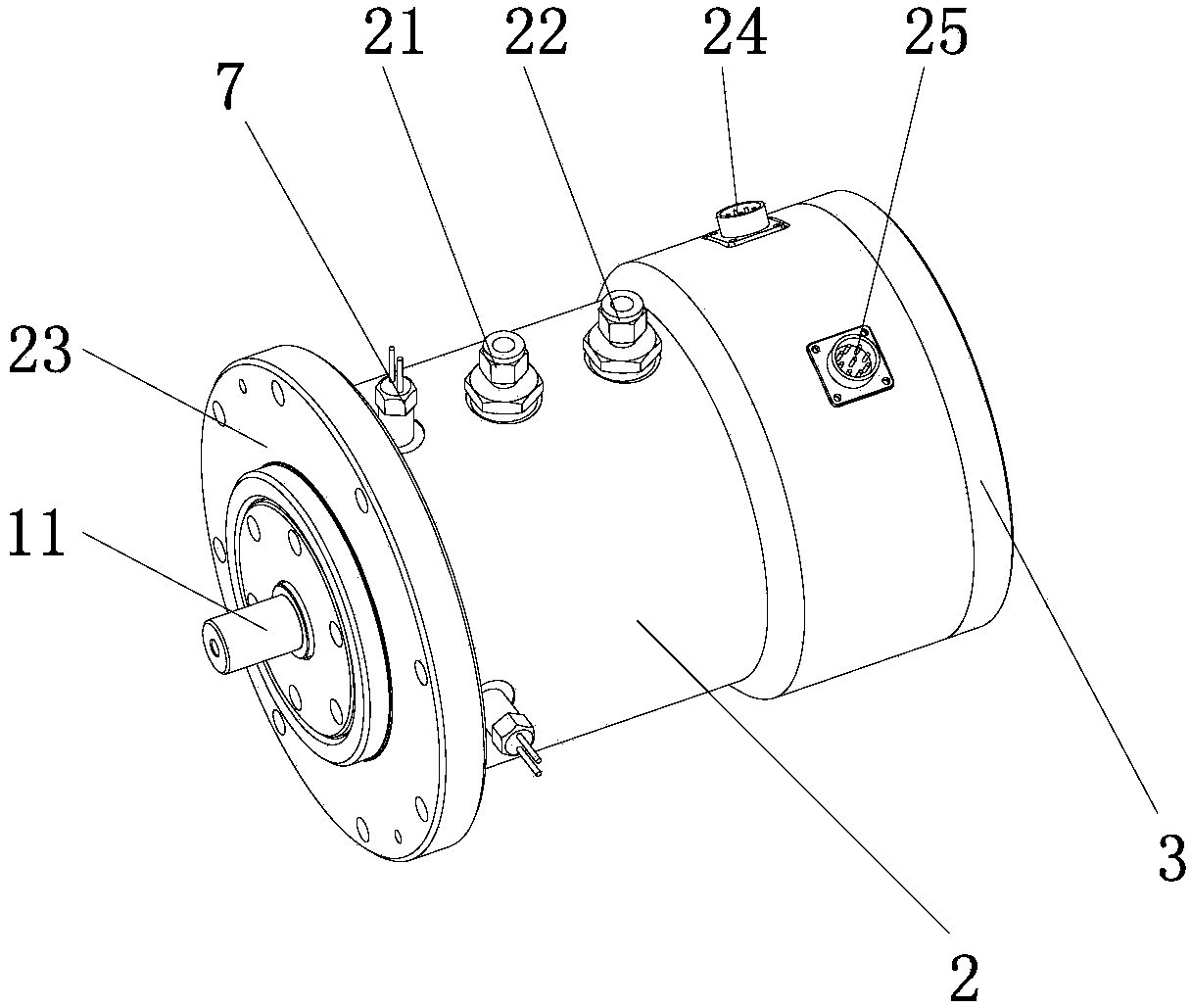

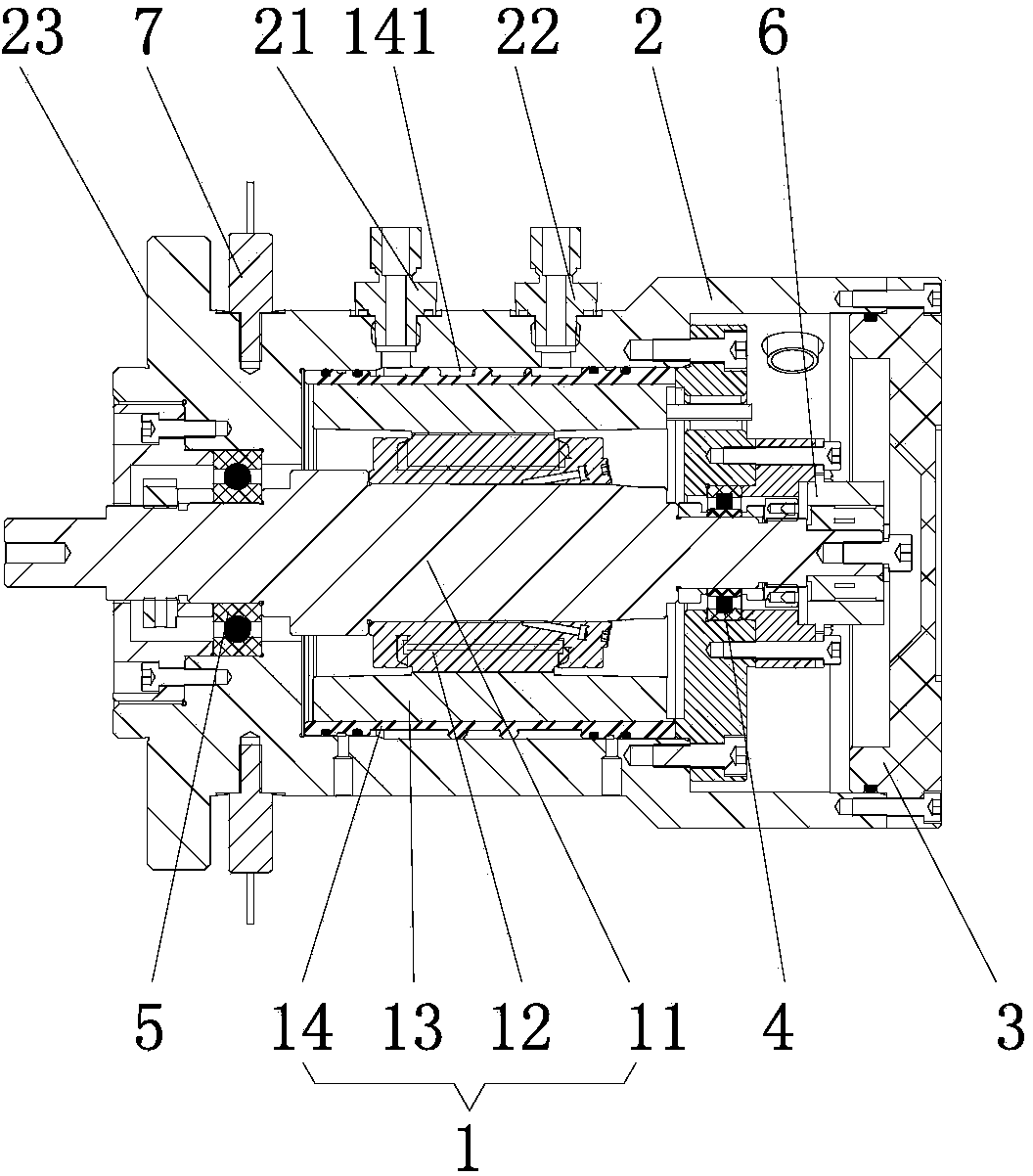

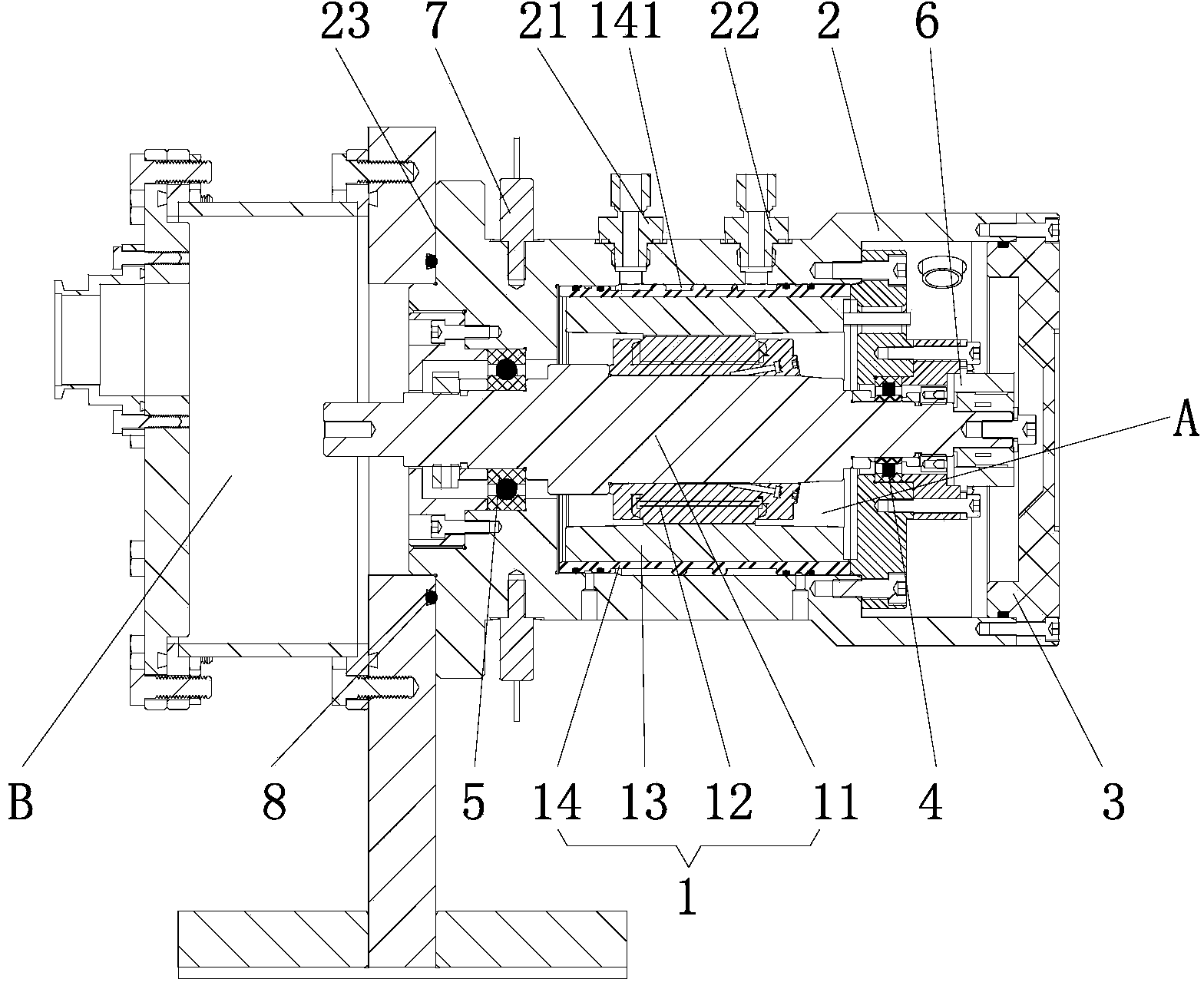

[0017] Attached below figure 1 to attach image 3 The present invention is described further:

[0018] Such as figure 1 with figure 2 The shown vacuum motor includes a motor main body 1, a motor housing 2 and a rear end cover 3, the motor main body 1 is arranged in the inner cavity of the motor housing 2, and the motor housing 2 is provided with a water inlet pipe joint 21 and a water outlet pipe joint 22 , the coolant enters the inner cavity of the motor housing 2 along the water inlet pipe joint 21 and flows out from the water outlet pipe joint 22 after cooling the motor body 1, the rear end cover 3 is sealed with the rear end of the motor housing 2, and the The front end face is a flat and smooth flange end face 23 . In this embodiment, cooling water is used as the cooling liquid.

[0019] In this embodiment, the motor body 1 adopts a built-in motor structure. The motor body 1 includes a main shaft 11, a rotor 12, a stator 13 and a cooling cover 14. The rotor 12 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com