Sealed Claw Pole Axial Magnetic Permanent Magnet Brushless DC Motor

A DC motor and axial magnetic circuit technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electric components, etc., can solve the problem that the brush motor cannot meet the high life requirements of the engine, the difficulty of layout, the complexity of quality control, and the unfavorable system integration and other problems, to achieve the effect of reducing the probability of corrosion failure, large torque, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

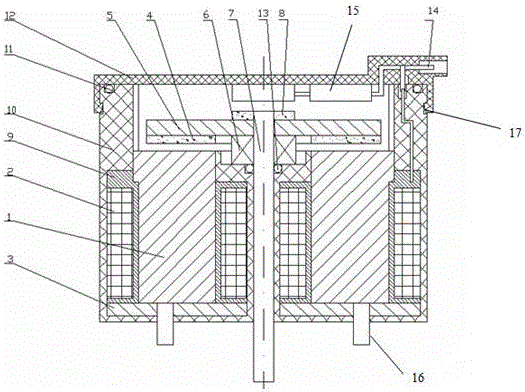

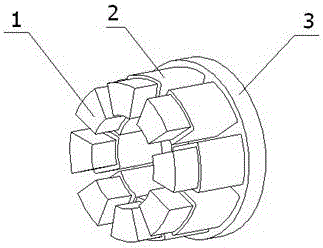

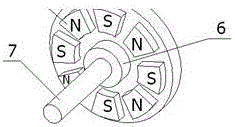

[0022] Please refer to the accompanying drawings, the stator of the motor of the present invention is vertically and uniformly fixed claw poles 1 around a base 3, the center line of the claw poles 1 is parallel to the axis of the rotating shaft 7, and the coil winding 2 is placed on the claw poles 1. The base of the motor stator 3. The coil winding 2 on the claw pole 1 of the base is covered with plastic material 10 to form a barrel-shaped plastic seal, and a cover 12 is sealed on the barrel-shaped plastic seal. The rotating shaft 7 of the motor rotor passes through the stator base 3, Fix an iron core 5 vertically, fix the permanent magnet magnetic steel 4 evenly on the iron core 5, and fix a sensor magnetic steel 8 at the center of the other surface of the iron core 5. Corresponding to the sensor 15, the sensor used in the present invention has no PCB board structure, and the Hall sensor is packaged in one piece, which avoids the risk of failure of common PCB board electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com