Water sealing device applied to hydraulic fracture experiment under high-temperature and high-pressure condition

A hydraulic fracturing, high temperature and high pressure technology, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc. Good ductility, good sealing effect, and the effect of overcoming failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

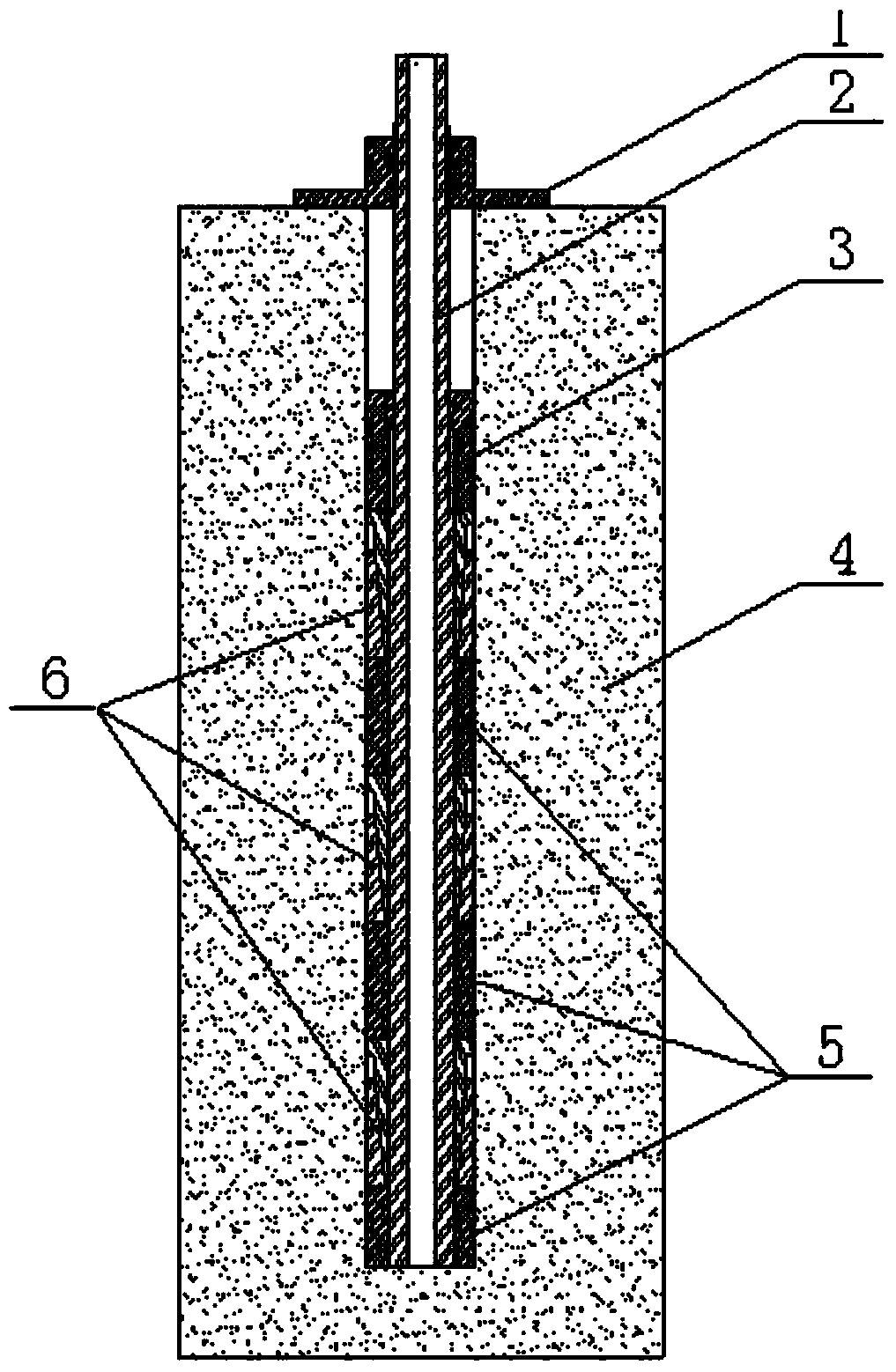

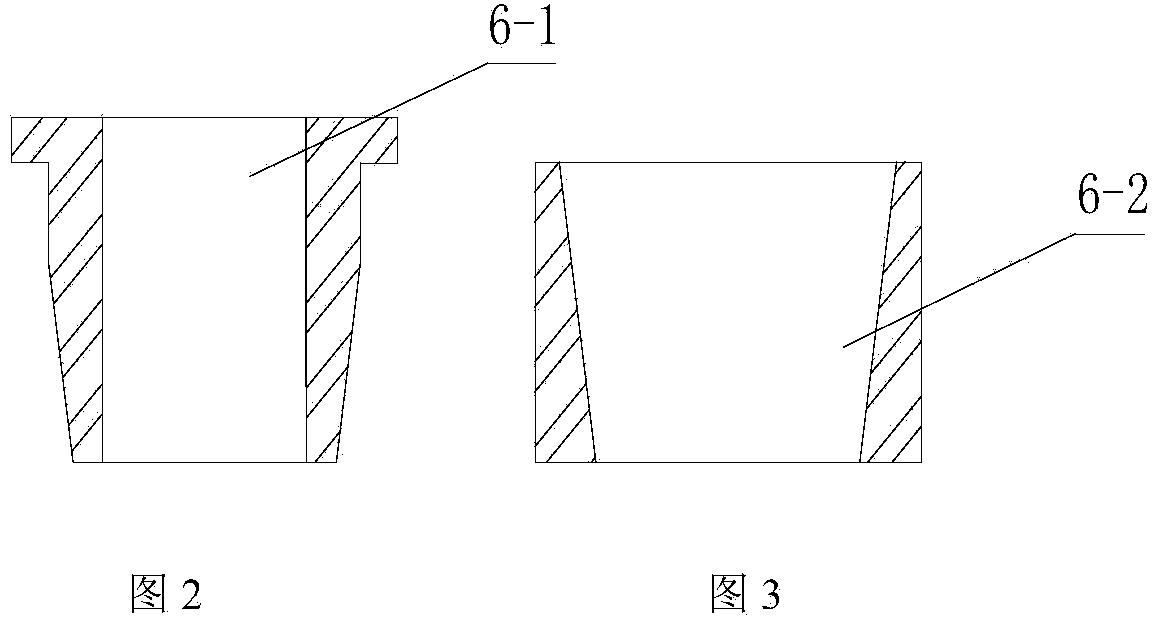

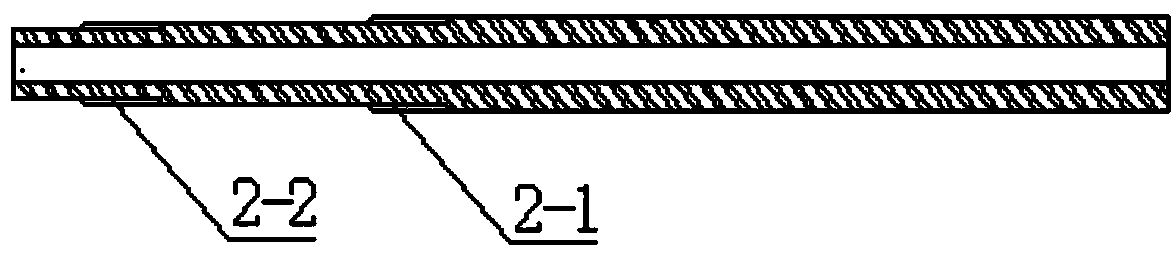

[0018] Such as figure 1 As shown, the present invention is based on the water sealing device of the rock sample hydraulic fracturing experiment under the high temperature and high pressure environment, and mainly consists of a sealing nut 1, a metal water pipe 2, a lock nut 3, a rock sample 4, a metal washer 5 and a wedge seal Composed of 6 copper rings. A blind hole is opened on the rock sample 4, and a metal water pipe 2 is inserted into the blind hole of the rock sample 4, and a plurality of metal washers 5 and wedge-shaped sealing copper rings 6 are set at intervals on the metal water pipe 2 in the blind hole. A plurality of metal washers 5 and wedge-shaped sealing copper rings 6 are provided with locking nuts 3 matched with the metal water pipe 2, and the exposed end of the metal water pipe 2 is provided with a sealing nut 1 for sealing the orifice of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com