Method for distinguishing temperature of outer wall of cracking furnace tube from temperature of inner wall of hearth and measurement device

A furnace inner wall and temperature measurement technology, which is applied in the field of petrochemical industry, can solve the problems of low frequency and accuracy of temperature measurement, serious operator interference, and harsh temperature measurement environment, so as to improve measurement accuracy, high temperature resolution, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

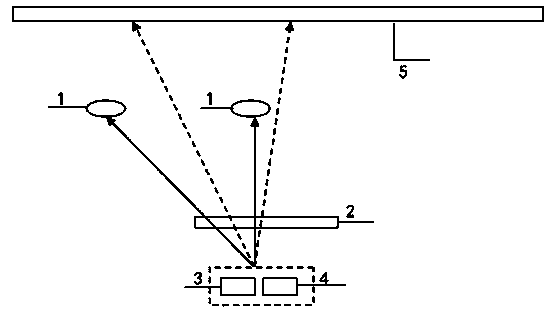

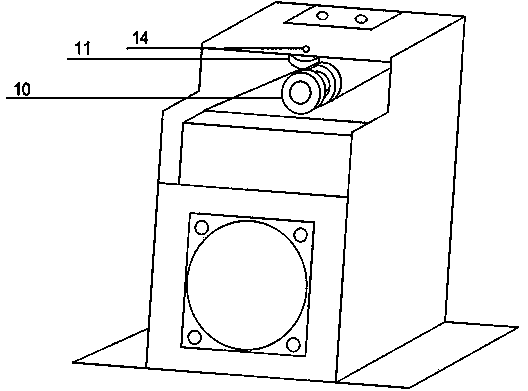

[0034] Such as figure 1 As shown, a temperature screening method for the outer wall of the cracking furnace tube and the inner wall of the furnace, when the temperature measurement module 3 measures the temperature of the outer wall of the cracking furnace tube 1, the distance of the measured object is synchronously measured by the distance measurement module 4, and according to the measured distance It is discriminated whether the measured temperature is the temperature of the outer wall of the furnace tube 1 or the inner wall temperature of the furnace 5 .

[0035] Further, the temperature measurement module 3 and the distance measurement module 4 are focused before the measurement, so as to ensure that the temperature measurement module 3 and the distance measurement module 4 measure the same object synchronously.

[0036] Further, the temperature and distance measured by the temperature measurement module 3 and the distance measurement module 4 are synchronously transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com