Manufacturing method and application of whole-flow-passage double-face-heat-collection rare earth aluminum alloy solar panel

A technology of solar thermal collectors and solar thermal collectors, applied in the field of solar thermal collectors, can solve the problems of not being able to adjust hot water production according to the weather, not being fully utilized, and affecting heat collection and heat transfer efficiency, etc., to achieve direct heat transfer Increased heat area, improved heat collection and heat transfer efficiency, faster and more direct heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

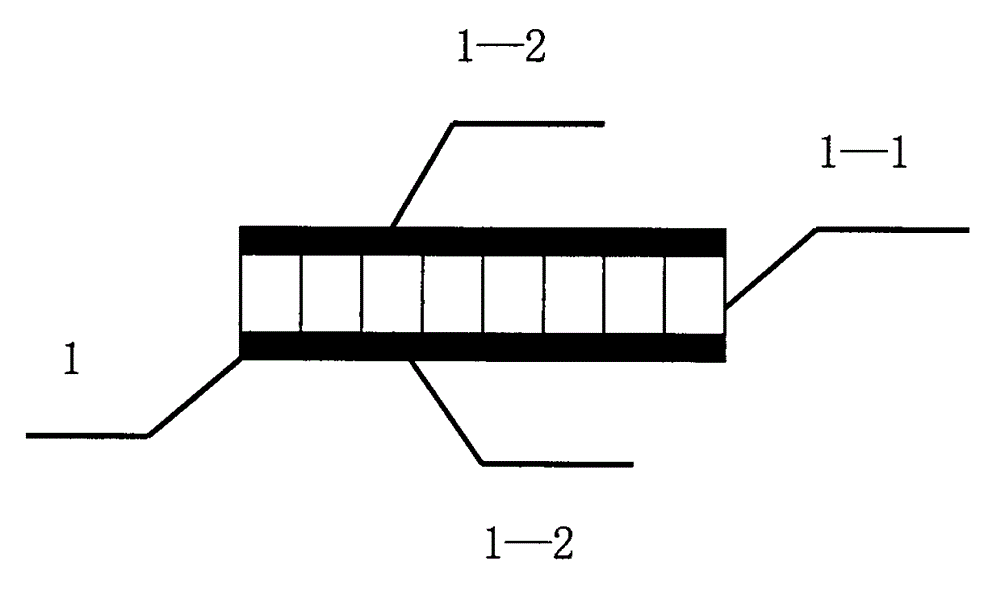

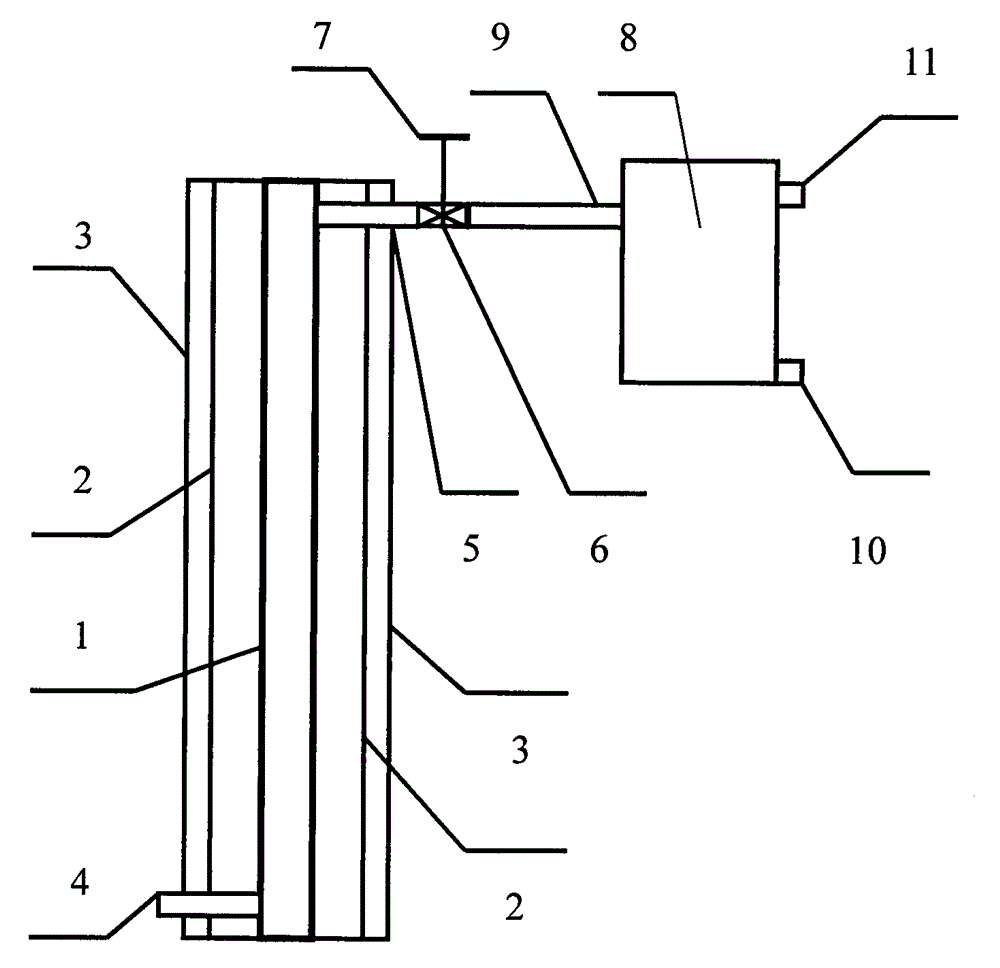

[0016] See attached figure 1 . A method for manufacturing a full-channel double-sided heat-collecting rare-earth aluminum alloy solar heat collecting plate, characterized in that: using the aluminum alloy door and window material production process, the rare-earth aluminum alloy is extruded through a full-channel mold into a full-channel rare earth aluminum alloy panel For the hot plate green body, in addition to chemically treating the front surface of the green body to become a solar heat collecting layer, the back surface of the green body is also chemically treated to become a solar heat collecting layer, or in addition to spraying solar energy absorbing paint on the front surface of the green body In addition, the solar energy absorbing paint is sprayed on the back surface of the green body, and the base layer is made of a full-channel rare earth aluminum alloy structure layer 1-1, and the front surface layer and the back surface layer are full-flow channels of the solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com