Steam generation device and steam generation method

A steam generating device and steam technology, applied in the field of test instruments, can solve the problems of cumbersome process, inconvenient control and operation, complicated system, etc., and achieve the effect of ensuring normal shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

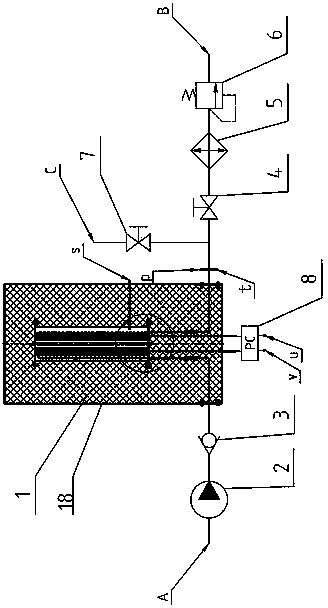

[0039] Embodiment 1 is the steam generating device related to the present invention, in combination with the attached figure 1 and figure 2 illustrate.

[0040] figure 1 Among them, the water pump 2, the electric heater 1, the one-way valve 3, the first on-off valve 4, the condenser 5, and the back pressure valve 6 are connected in sequence through pipelines, and the pipeline between the first on-off valve 4 and the electric heater 1 A steam output bypass is set on the road, and a second on-off valve 7 is set on the steam output bypass. The electric heating wire 13 on the electric heater 1 is connected to the power controller 8, and the power controller 8 is connected to the power supply through the v head and the u head; the output port of the electric heater 1 is provided with a four-way joint, and the p port of the four-way joint is set for pressure sensor, the q port is provided with a temperature sensor.

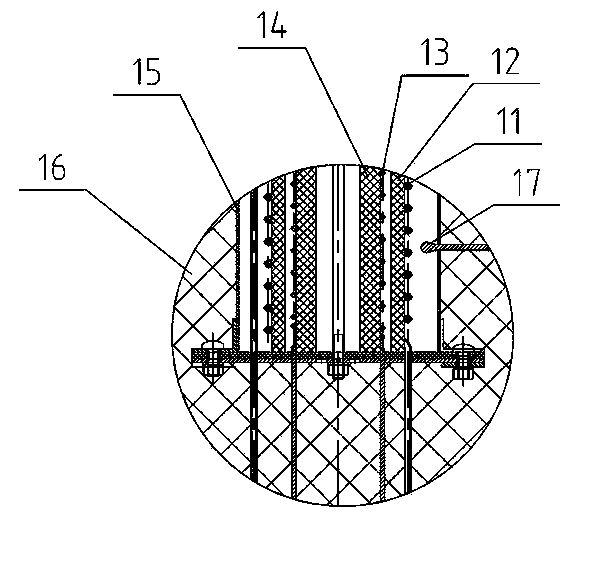

[0041] figure 2 yes figure 1Partial enlarged view, as show...

Embodiment approach 2

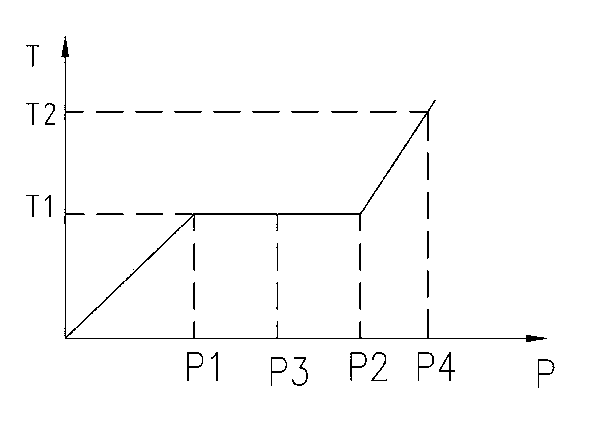

[0047] Embodiment 2 is a method of using the steam generating device of Embodiment 1 to generate steam with a certain degree of dryness, combined with the attached figure 1 , 2 , 3 instructions.

[0048] First set the flow rate and pressure of the pump 2 and the pressure of the back pressure valve 6, connect the power supply of the v head and the u head, and control the power of the input electric heating wire 13 through the power controller 8; the water in the heating water pipe 11 absorbs heat, and the temperature increases , The volume expands, and the pressure increases accordingly. The pressure of the output port is monitored through the p port, and the temperature of the outlet is monitored through the t port. Under the action of the back pressure valve, the pressure of the water remains constant and finally reaches an equilibrium state.

[0049] Then increase the input power of the electric heating wire 13 by the power controller 8, monitor the pressure and temperature...

Embodiment approach 3

[0055] Embodiment 3 is a method for generating superheated steam using the steam generating device of Embodiment 1, combined with the attached figure 1 , 2 , 3 instructions.

[0056] Firstly, the same method as Embodiment 2 will be used to obtain saturated steam with a dryness of 100%. Through the power controller 8 to continue to increase the output power, the steam at the output port will get more heat, thereby transitioning from saturated steam to superheated steam. During the power increase process, the temperature of the superheated steam will also continue to rise. When the steam temperature is T2, the input power is P4, and the required superheated steam can be obtained by stabilizing the input power at P4 through the power controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com