Rubber seal desulfurization and denitrification knife gate valve

A technology of desulfurization, denitrification and rubber sealing, applied in the field of knife gate valves, can solve the problems of large contact area, internal leakage and external leakage, and inability to evenly tighten bolts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention and its effects will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

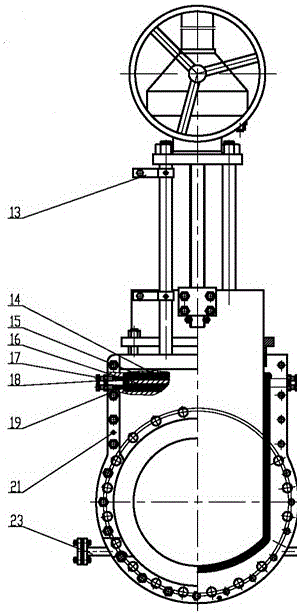

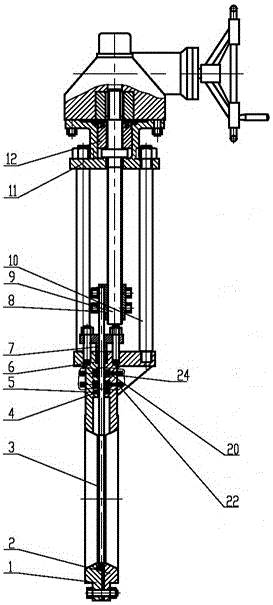

[0025] refer to Figure 1a , 1b, 2, 3, a rubber seal The desulfurization and denitrification knife gate valve includes a gate plate. The valve body of the knife gate valve is divided into left and right valve bodies 1 and 2, which are integrally cast respectively, which is convenient for precision machining on a CNC machining center; and can reduce the weight of the valve.

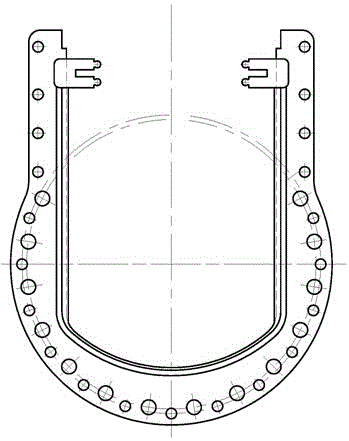

[0026] A sealing device is provided between the left and right valve bodies 1 and 2; the sealing device includes a skirted U-shaped gasket 15 placed between the left and right valve bodies 1 and 2, and the meaning of the so-called skirt is U The outer edge of the U-shaped gasket extends to the outer edge of the knife gate valve to match it, while the inner edge is embedded in the groove of the valve body. The skirted U-shaped gasket 15 is made of Viton r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com