Planet differential motion reduction gearbox with interlayer air cooling box body supported by zinc base alloy bearings

A technology of alloy bearings and differential deceleration, which is applied in transmission parts, gear lubrication/cooling, belts/chains/gears, etc. It can solve the problems that the gearbox does not have heat dissipation function, high cost, low thermal power, etc., and achieve structural Simple, low manufacturing cost, high thermal power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

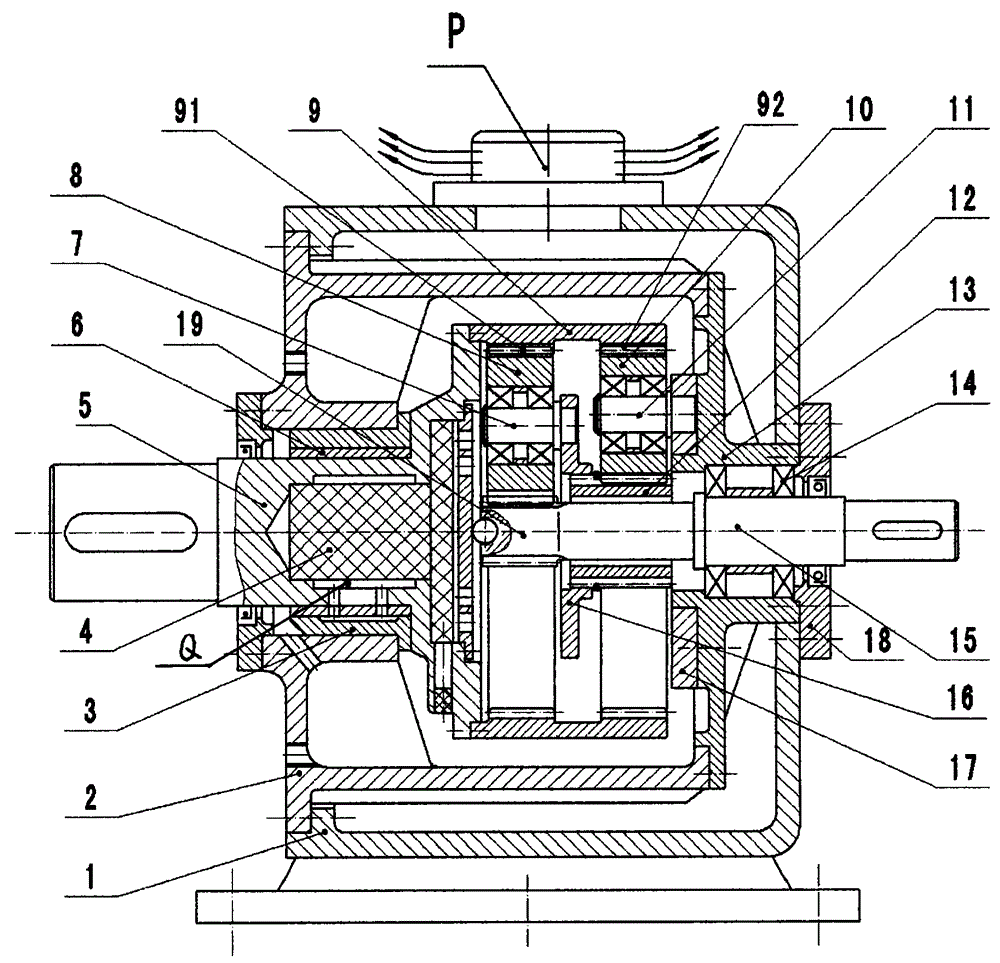

[0043] [Detailed embodiments] The present invention will be described in detail below with reference to the drawings:

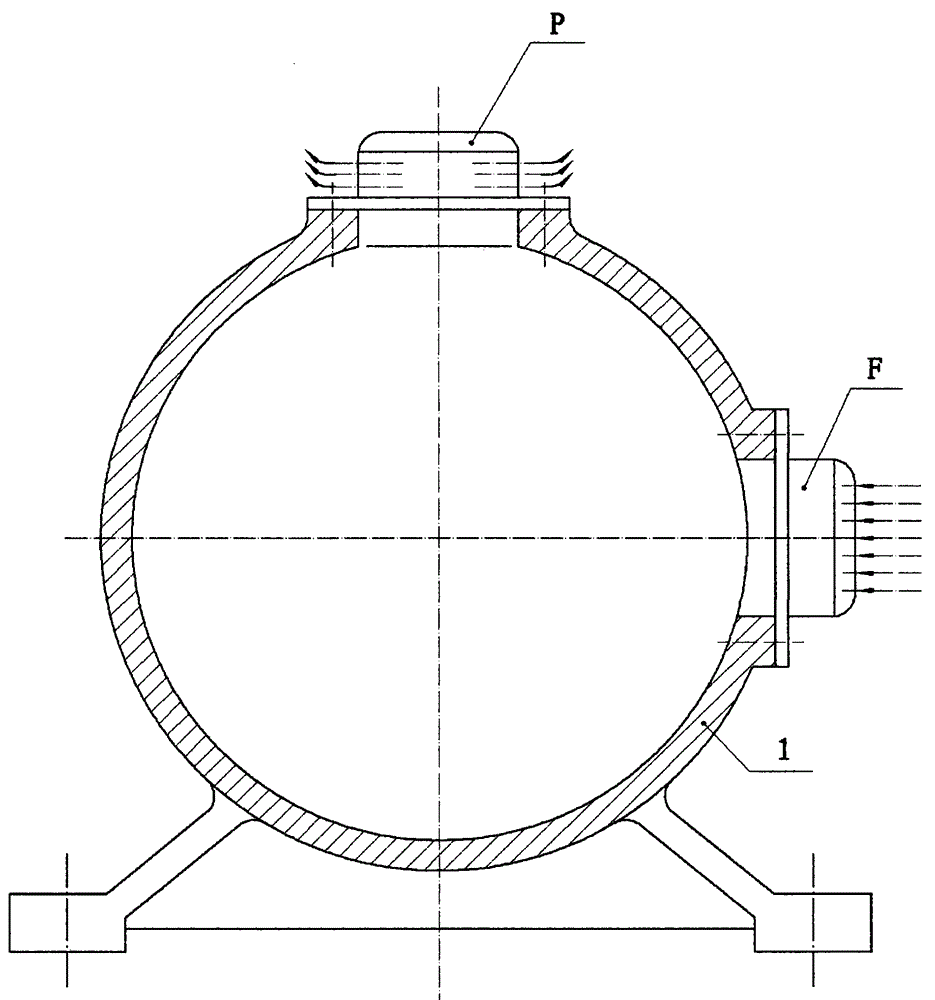

[0044] Reference figure 1 ., 2 A planetary differential gearbox supported by zinc-based alloy bearings in a sandwich air-cooled box, comprising a box body 1 and an input shaft 15 arranged in the box body 1 and sequentially driven, a differential-quasi-planetary component and an output shaft 5. It is characterized by:

[0045] The box body 1 is provided with a connecting piece between the inner cylinder 2 and the round end cover 13, the inner cylinder 2 flange is connected to the output end surface of the box body 1, and the outer circle of the input end of the round end cover 13 is connected to the box body. 1 The inner hole of the input end is tightly matched, the input end face of the round end cover 13 and the round end face of the input end of the box body 1 are sealed and connected with the same ring disk 18, the built-in cylinder 2 and the round end cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com