A kind of polymer composite paint for building and preparation method thereof

A composite coating and polymer technology, applied in the direction of coating, can solve the problems of poor electrical conductivity, insignificant electromagnetic shielding performance, poor oxidation resistance, etc., and achieve high physical properties and heat resistance, good electromagnetic shielding effect, good waterproof. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

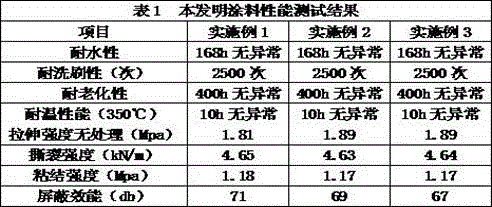

Examples

Embodiment 1

[0013] Example 1: (1), 9 grams of serpentine powder with a particle diameter of 2 to 5 um, 7 grams of phosphogypsum powder with a particle diameter of 5 to 10 um, 1.2 grams of triethanolamine, 2.5 grams of sodium benzenesulfinate, stearic acid 5 grams of zinc; added to 45 grams of Bardfu 998A styrene-acrylic emulsion, stirred at a speed of 600-800 rpm for 30 minutes to obtain mixture A;

[0014] (2) Add 2 grams of sodium dodecylbenzenesulfonate, 4 grams of praseodymium neodymium alloy powder with a particle size of 1-2um, 7.5 grams of nano-iron powder with a particle size of 20-30nm, and tellurium powder with a particle size of 2-3um. 2 grams of powder, mixed and stirred evenly; added to another 20 grams of Bardfu 998A styrene-acrylic emulsion, and stirred for 80 minutes with an Adap YPS59 ultrasonic solution mixer; to obtain mixture B;

[0015] (3) Mix mixture A and mixture B in step (1) and step (2), and stir at a speed of 800-1000 rpm for 10 minutes.

Embodiment 2

[0016] Example 2: (1), 9 grams of serpentine powder with a particle diameter of 2 to 5 um, 6 grams of phosphogypsum powder with a particle diameter of 5 to 10 um, 1 gram of triethanolamine, 2 grams of sodium benzenesulfinate, stearic acid 5 grams of zinc; added to 41 grams of Bardfu 998A styrene-acrylic emulsion, stirred at a speed of 600-800 rpm for 30 minutes to obtain mixture A;

[0017] (2) Add 1.5 grams of sodium dodecylbenzenesulfonate, 3.5 grams of praseodymium neodymium alloy powder with a particle size of 1-2um, 7 grams of nano-iron powder with a particle size of 20-30nm, and tellurium powder with a particle size of 2-3um. 1.5 grams of powder, mixed and stirred evenly; added to another 17 grams of Bardfu 998A styrene-acrylic emulsion, and stirred for 80 minutes with an Adap YPS59 ultrasonic solution mixer; to obtain mixture B;

[0018] (3) Mix mixture A and mixture B in step (1) and step (2), and stir at a speed of 800-1000 rpm for 10 minutes.

Embodiment 3

[0019] Example 3: (1), 12 grams of serpentine powder with a particle diameter of 2 to 5 um, 9 grams of phosphogypsum powder with a particle diameter of 5 to 10 um, 1.5 grams of triethanolamine, 3 grams of sodium benzenesulfinate, stearic acid 6 grams of zinc; added to 46 grams of Bardfu 998A styrene-acrylic emulsion, stirred at a speed of 600-800 rpm for 30 minutes to obtain mixture A;

[0020] (2) Add 2 grams of sodium dodecylbenzenesulfonate, 4.5 grams of praseodymium neodymium alloy powder with a particle size of 1-2um, 8 grams of nano-iron powder with a particle size of 20-30nm, and tellurium powder with a particle size of 2-3um. 2.5 grams of powder, mixed and stirred evenly; added to another 20 grams of Bardfu 998A styrene-acrylic emulsion, and stirred for 80 minutes with an Adap YPS59 ultrasonic solution mixer; to obtain mixture B;

[0021] (3) Mix mixture A and mixture B in step (1) and step (2), and stir at a speed of 800-1000 rpm for 10 minutes.

[0022] Scratch-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com