A process for treating waste water from slate production

A technology for the production of waste water and treatment process, which is applied in the direction of special compound water treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems that are difficult to meet the needs of pollution control, and achieve convenient daily maintenance, Good effluent quality and large treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

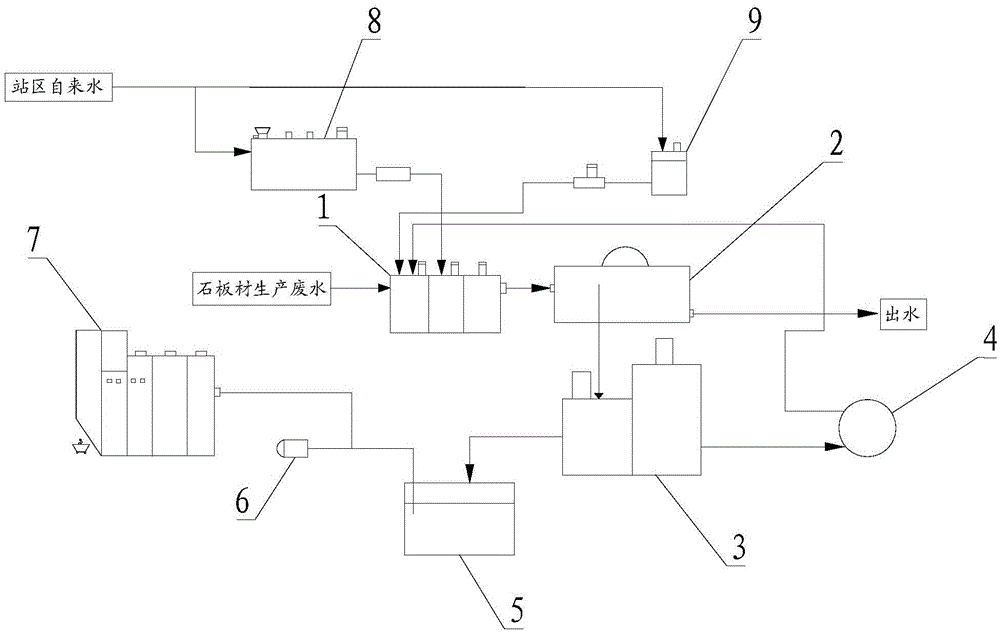

[0035] 1. Dilute the waste water from the production of stone slabs to be treated by 20m 3 The speed of / min is added in the coagulation reactor 1, and in the coagulation reactor 1, a magnetic seed (Fe with an organic film with active groups grown on the surface) 3 o 4 , the particle size is 2-10μm, and the amount added is 150g / m according to the amount of waste water from stone plate production to be treated 3 ), stirring at a speed of 450r / min for 1min, then reducing the speed to 70r / min, and adding the coagulation aid PAM (the average molecular weight is 15 million to 20 million, and the concentration is 2 ‰, the amount added is 0.75g / m3 based on the amount of waste water from stone slab production to be treated 3 ), add coagulant PAC (aluminum chloride content is 8wt% by PAC dosing device 9 in coagulation reactor 1, and the amount of addition is calculated as 3g / m by the amount of stone plate material production wastewater to be treated 3 ), stirring for 1min to carry o...

Embodiment 2

[0039] 1. Dilute the waste water from the production of stone slabs to be treated by 30m 3 The speed of / min is added in the coagulation reactor 1, and in the coagulation reactor 1, a magnetic seed (Fe with an organic film with active groups grown on the surface) 3 o 4 , the particle size is 2-10μm, and the amount added is 200g / m3 based on the amount of waste water from stone plate production to be treated 3 ), stirred at a speed of 500r / min for 2min, then reduced the speed to 250r / min, and added the coagulant PAM (the average molecular weight is 15 million to 20 million, and the concentration is 2 ‰, the amount added is 0.90g / m3 based on the amount of waste water from stone slab production to be treated 3 ), add coagulant PAC (aluminum chloride content is 15wt%) in coagulation reactor 1 by PAC dosing device 9, and the amount of addition is calculated as 6g / m by the amount of stone plate production wastewater to be treated 3 ), stirring for 2min to carry out coagulation rea...

Embodiment 3

[0043] 1. Dilute the waste water from the production of stone slabs to be treated by 25m 3The speed of / min is added in the coagulation reactor 1, and in the coagulation reactor 1, a magnetic seed (Fe with an organic film with active groups grown on the surface) 3 o 4 , the particle size is 2-10μm, and the amount added is 180g / m3 based on the amount of waste water from stone plate production to be treated 3 ), stirring at a speed of 480r / min for 1.5min, then reducing the speed to 100r / min, and adding coagulant PAM (average molecular weight is 15 million to 20 million, concentration is 2‰, the amount added is 0.80g / m3 based on the amount of waste water from stone slab production to be treated 3 ), add coagulant PAC (aluminum chloride content is 10wt%) in coagulation reactor 1 by PAC dosing device 9, and the amount of addition is calculated as 5g / m by the amount of stone plate material production wastewater to be treated 3 ), stirred for 1.5min to carry out coagulation reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com