Oil press with safety device

A technology for safety devices and oil presses, which is applied in engineering safety devices, presses, mechanical equipment, etc., can solve problems such as unsustainable pressing and potential safety hazards, and achieve the goal of overcoming small materials or residues that are easy to remain, avoiding potential safety hazards, and facilitating cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and implementation examples. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

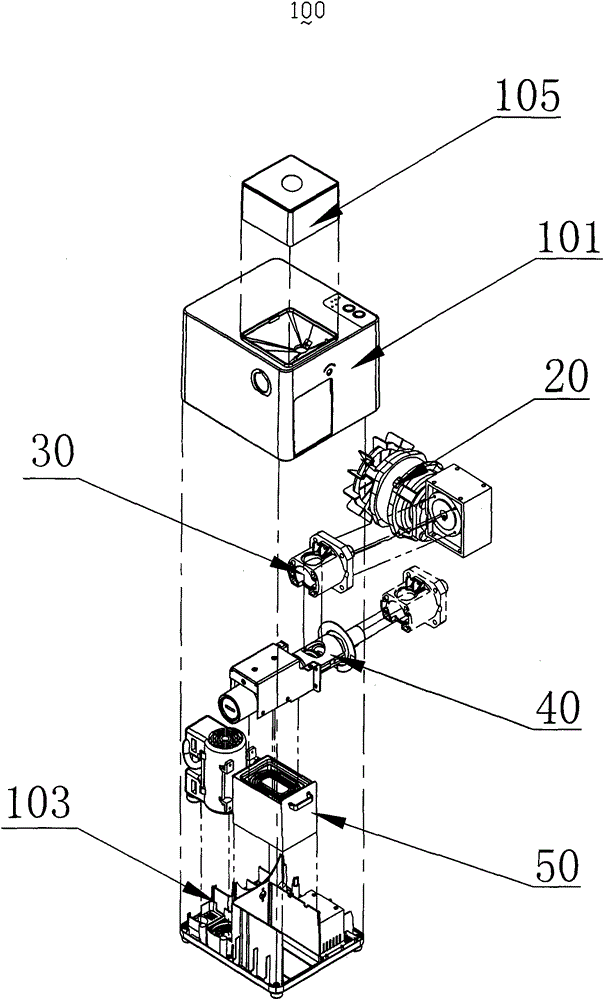

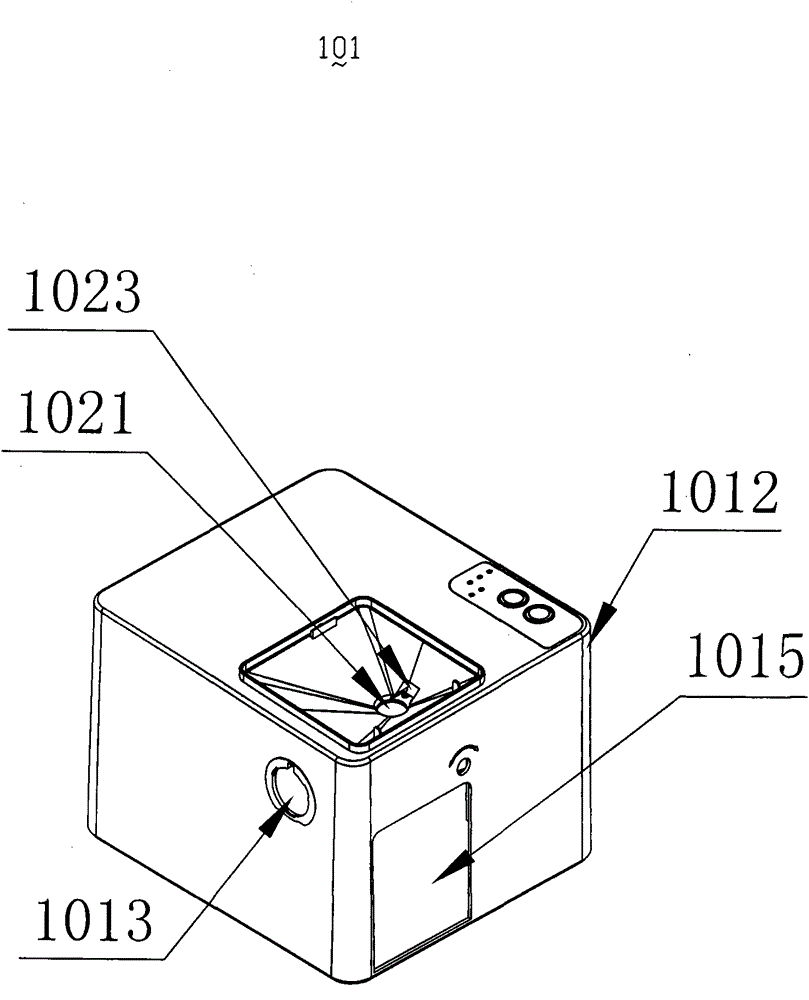

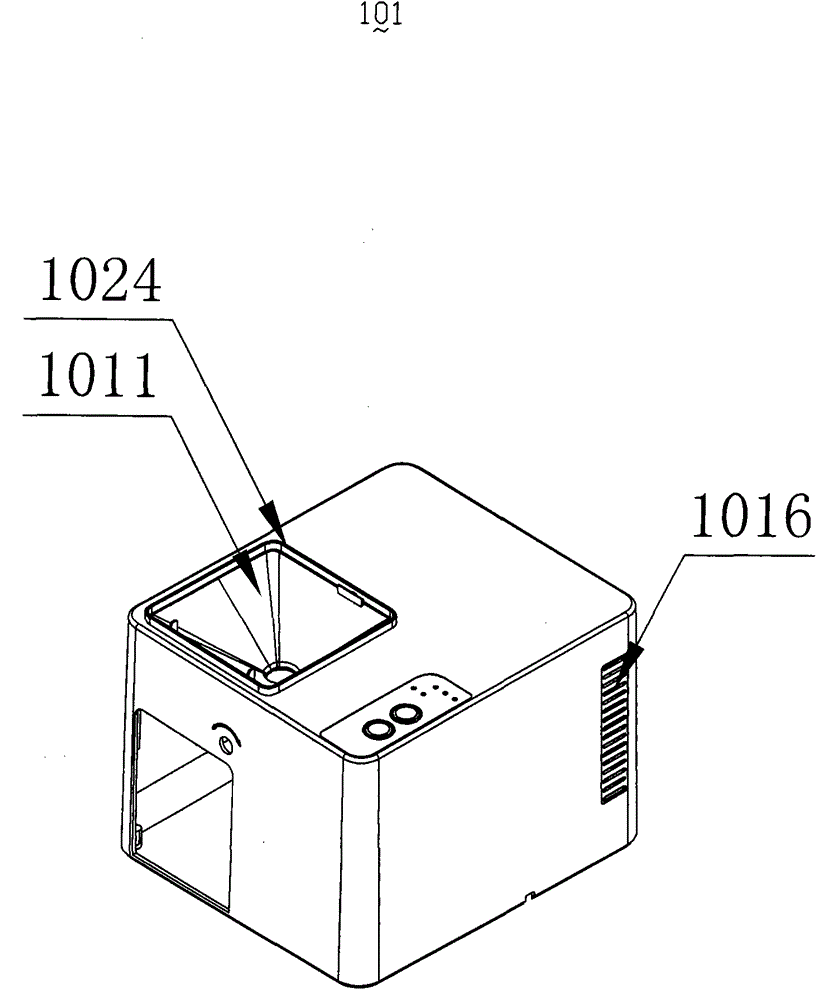

[0030] See figure 1 , The first embodiment of the present invention, a household oil press 100 includes a housing 10, a driving mechanism 20, a feeding mechanism 30, a pressing mechanism 40 and a recycling mechanism 50. The housing 10 includes a casing 101, a base 103 and a protective cover 105 After the cover 101 and the base 103 cooperate, a cavity is formed, and the driving mechanism 20, the feeding mechanism 30, the squeezing mechanism 40 and the recovery mechanism 50 are housed in it. The driving mechanism 20 provides a power source for the feeding mechanism 30 and the pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com