Continuous pyraclostrobin suspending agent preparation method

A technology of pyraclostrobin and suspending agent, which is applied in the field of preparation of pyraclostrobin suspending agent, can solve the problems of low utilization rate, achieve high utilization rate, significant progress, and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

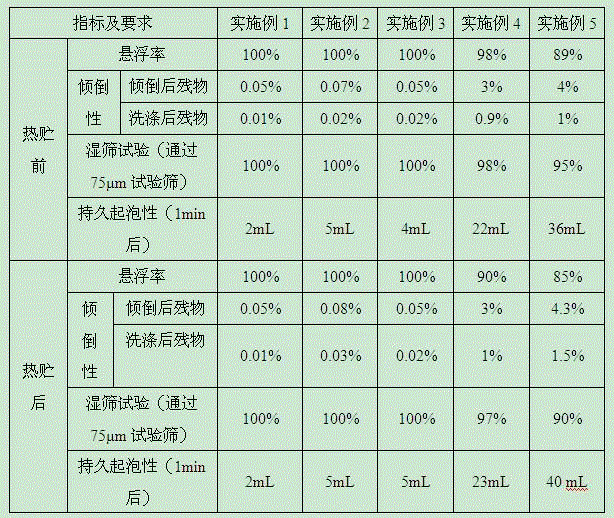

Examples

Embodiment 1

[0039] Embodiment 1: Utilize the method preparation of the present invention

[0040] 1: Take 100 grams of commercially available pyraclostrobin, add 5 grams of water, add 200 ml of methanol, heat up to 60 degrees, stir, all pyraclostrobin is dissolved, and slowly (according to the rate of 0.5 degrees per minute, cool down, ) Cool down to 20 degrees, crystals are precipitated, continue to cool down to 0-5 degrees, and keep warm at 0-5 degrees for 4 hours;

[0041] 2: Keep the temperature rising at a rate of 5 degrees per minute to raise the temperature. When the temperature rises to 40 degrees, some of the samples are not dissolved. Continue to cool down and keep the cooling rate at 5 degrees per minute; cool down to 0-5 degrees and keep for 4 hours.

[0042] 3: Repeat operation 2 for 3 times.

[0043] 4: After operation 3 is completed, distill methanol under reduced pressure until the methanol content of the residue is less than 1%, control the vacuum degree to less than 10...

Embodiment 2

[0046] Embodiment 2: Utilize the method preparation of the present invention

[0047] 1: Take 100 grams of commercially available pyraclostrobin, add 20 grams of water, add 200 ml of methanol, heat up to 64 degrees, stir, all pyraclostrobin is dissolved, and slowly (according to the rate of 1 ℃ per minute, cool down, ) Cool down to 10 degrees, crystals are precipitated, continue to cool down to 0-5 degrees, and keep warm at 0-5 degrees for 8 hours;

[0048] 2: Keep the temperature rising at a rate of 1 degree / minute to raise the temperature. When the temperature rises to 45 degrees, some of the samples are not dissolved. Continue to cool down, and the cooling rate is maintained at 1 degree / minute; cool down to 0-5 degrees and keep for 10 hours.

[0049] 3: Repeat operation 2 for 5 times.

[0050] 4: After operation 3 is completed, distill methanol under reduced pressure until the methanol content of the residue is less than 0.5%, control the vacuum degree to less than 20mmH...

Embodiment 3

[0053] Embodiment 3: Utilize the method preparation of the present invention

[0054] 1: Take 100 grams of commercially available pyraclostrobin, add 2 grams of water, add 200 ml of methanol, heat up to 40 degrees, stir, pyraclostrobin is completely dissolved, and slowly (according to the rate of 5 degrees per minute, cool down, ) Cool down to 20 degrees, crystals are precipitated, continue to cool down to 0-5 degrees, and keep warm at 0-5 degrees for 10 hours;

[0055] 2: Keep the temperature rising at a rate of 0.5 degrees per minute to raise the temperature. When the temperature rises to 30 degrees, some of the samples are not dissolved. Continue to cool down and keep the cooling rate at 2 degrees per minute; cool down to 0-5 degrees and keep for 24 hours.

[0056] 3: Repeat operation 2 for 2 times.

[0057] 4: After operation 3 is completed, distill methanol under reduced pressure until the methanol content of the residue is less than 2%, control the vacuum degree to less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com