TFT (thin film transistor) substrate and manufacturing method thereof

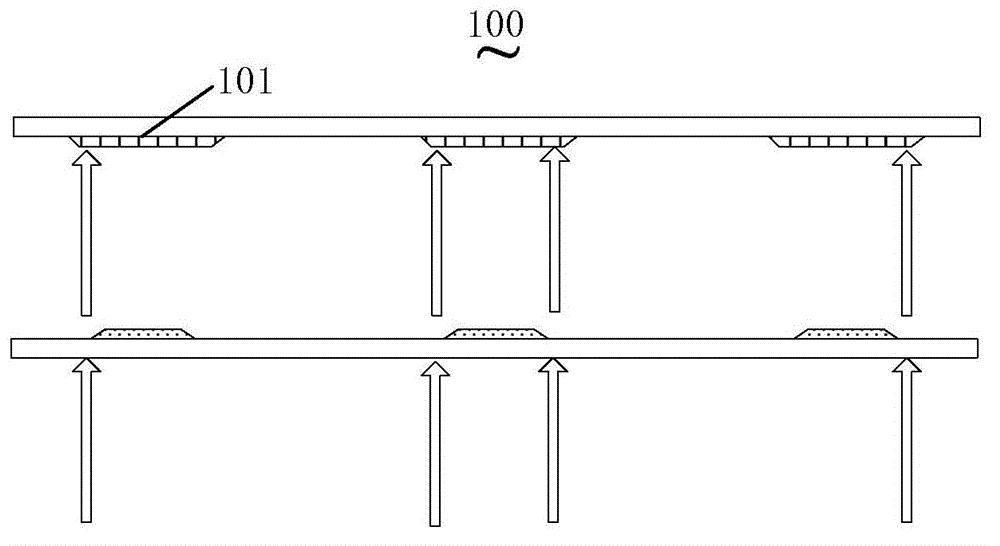

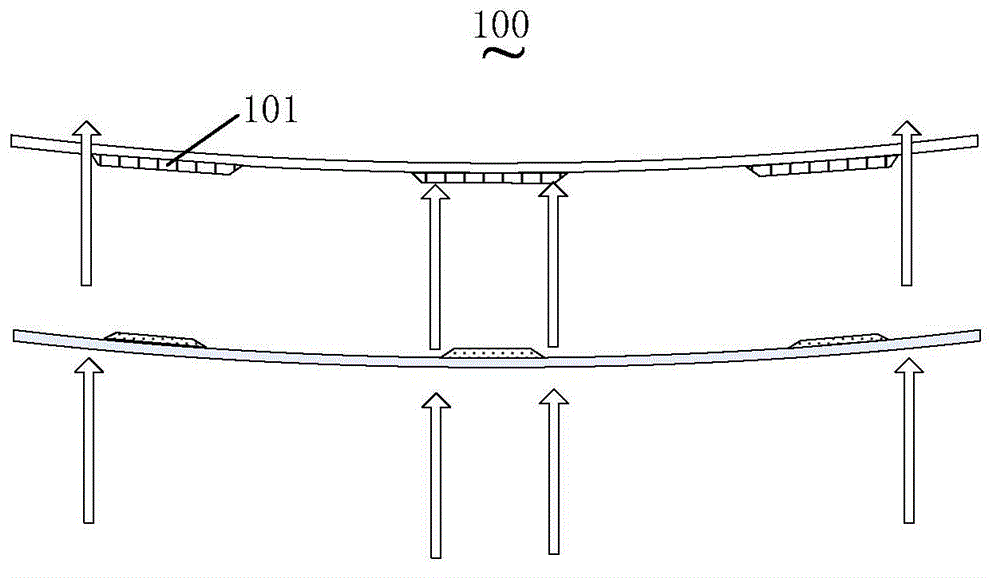

A manufacturing method and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of light leakage, affecting the shading effect of the black matrix 101, reducing the contrast of the panel, etc., to achieve the effect of ensuring the shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

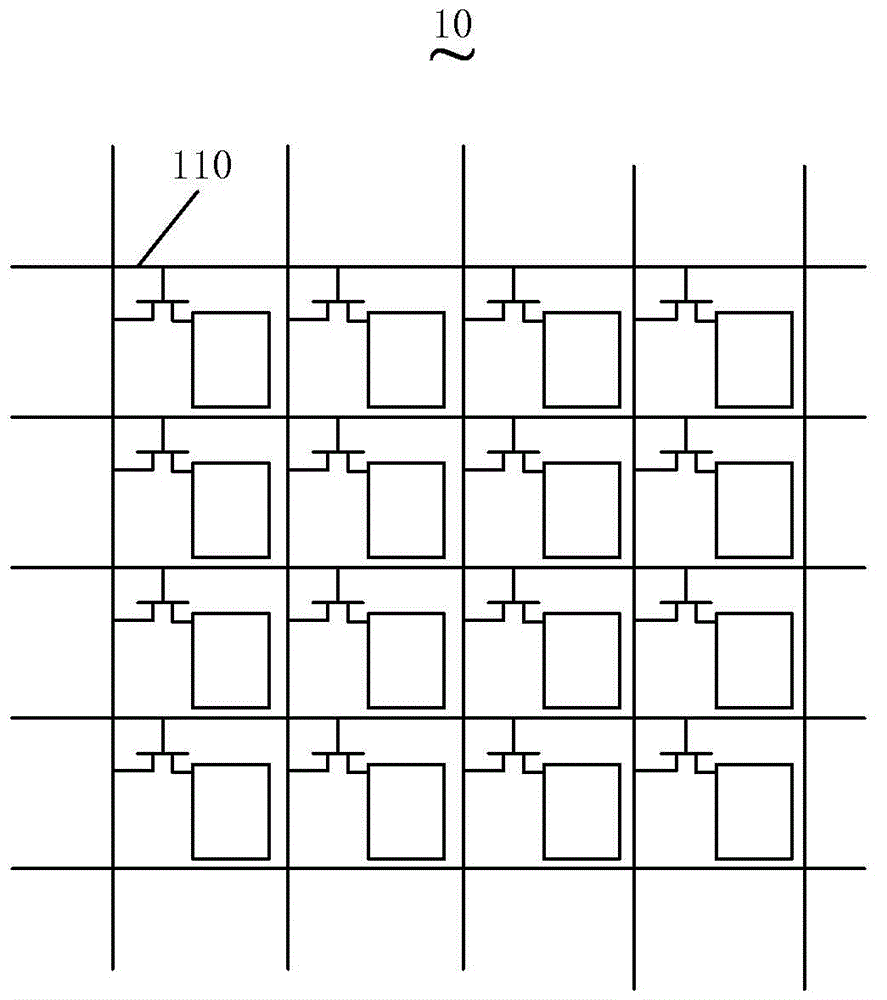

[0028] see image 3 , image 3 It is a schematic structural diagram of a TFT substrate provided by an embodiment of the present invention. The TFT substrate 10 of the embodiment of the present invention includes a plurality of pixel units 110, wherein each pixel unit 110 has the same structure. The structure of one of the pixel units 110 will be described below as an example.

[0029] Please also refer to Figure 4-Figure 7 , Figure 4 yes image 3 A schematic structural diagram of one of the pixel units of the TFT substrate shown, Figure 5 yes Figure 4 The cross-sectional view of the pixel unit shown along the dotted line EF, Figure 6 yes Figure 5 A magnified view of the region A shown, Figure 7 yes Figure 5 A magnified view of region B is shown. first as Figure 4 and Figure 5 As shown, the pixel unit 110 of the embodiment of the present invention includes a substrate 11, a gate electrode 12, a first insulating layer 13, an active layer 14, a black matrix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com