Leadless piezoresistive mems high-range acceleration sensor and manufacturing method thereof

An acceleration sensor, a piezoresistive technology, applied in the piezoresistive MEMS high-range acceleration sensor and its manufacturing field, can solve the problems of the limited application range of the piezoresistive high-range acceleration sensor, so as to solve the limited application range and avoid the Circuit failure, the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

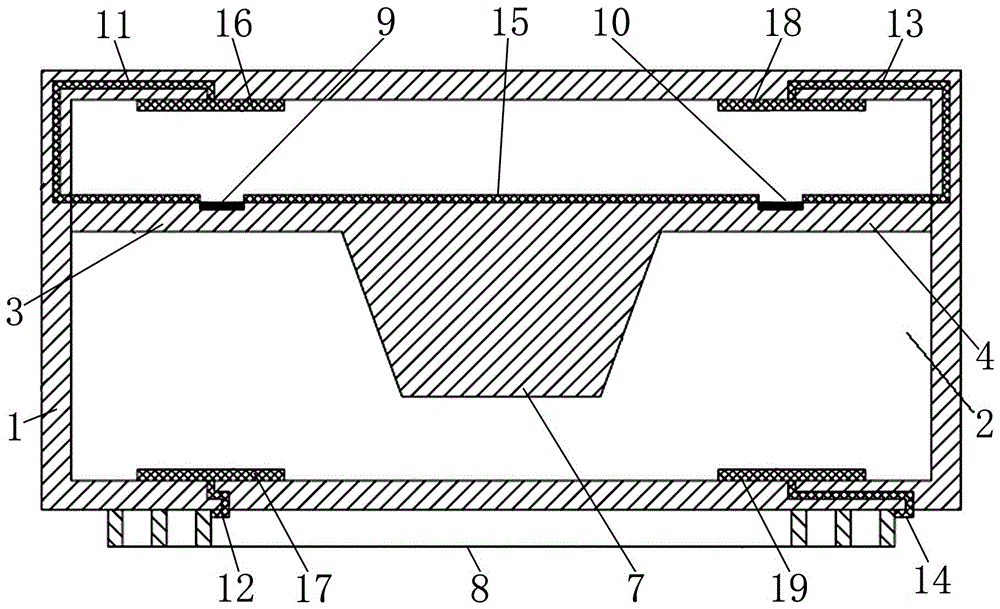

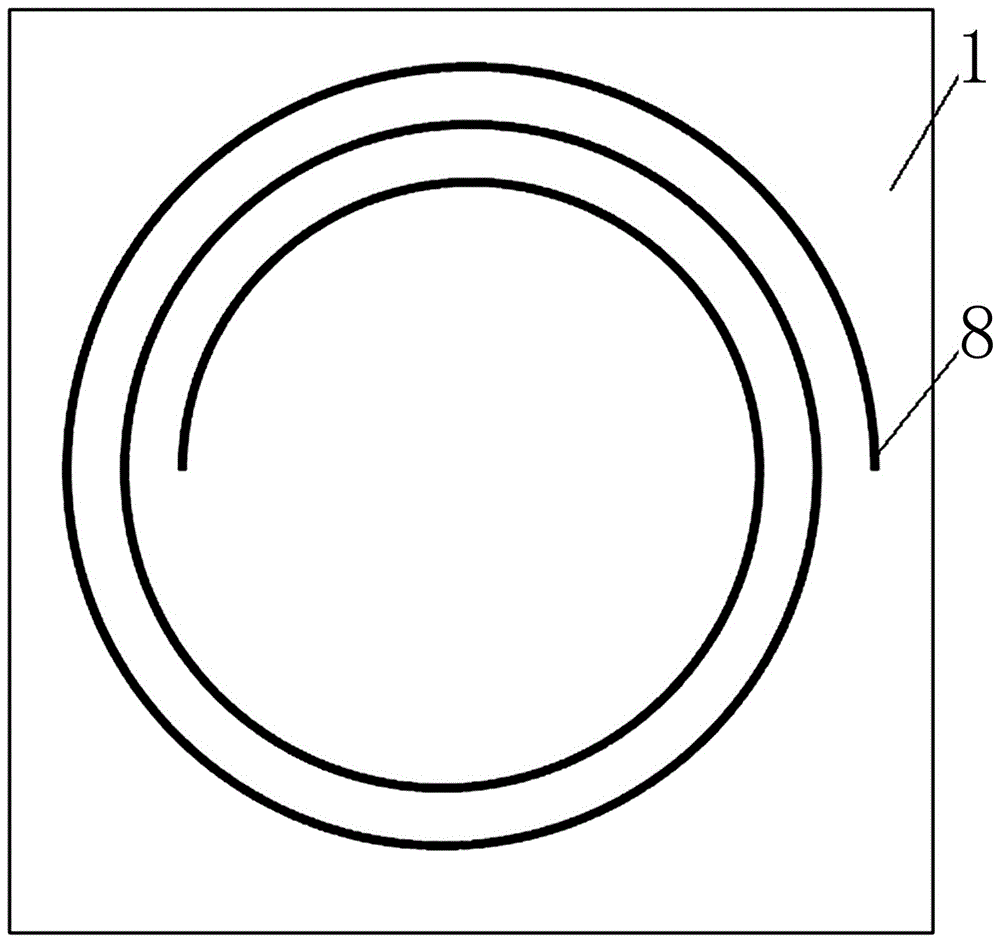

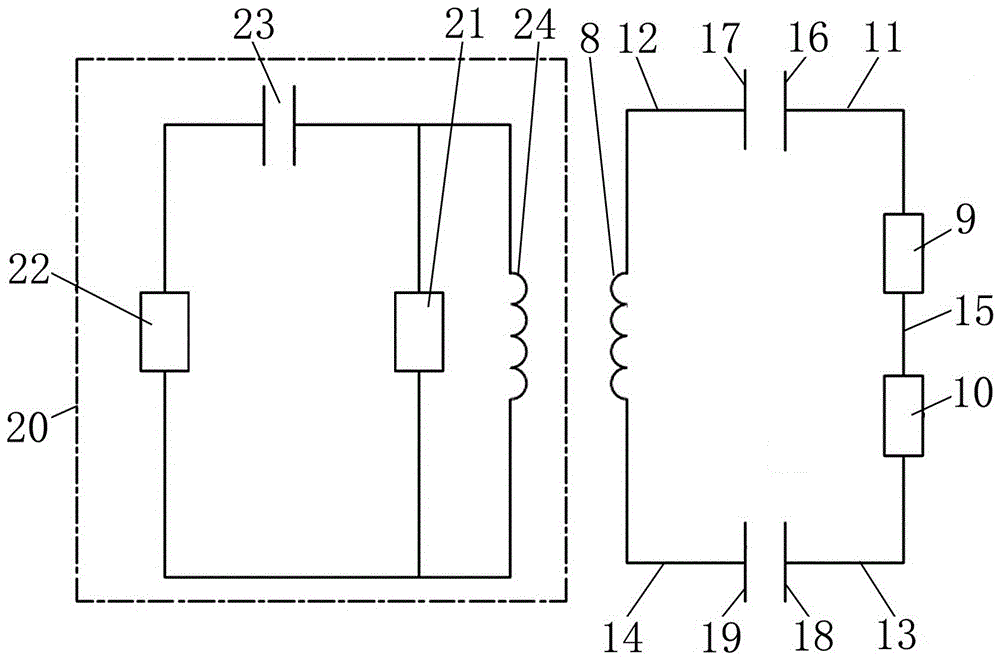

[0027] A leadless piezoresistive MEMS high-range acceleration sensor, including a substrate 1, a closed cavity 2, a first cantilever beam 3, a second cantilever beam 4, a third cantilever beam 5, a fourth cantilever beam 6, a mass block 7, Planar spiral inductor 8, first varistor 9, second varistor 10, first capacitor, second capacitor, first wire hole, second wire hole, third wire hole, fourth wire hole, first electrical connection 11. The second electrical connection 12, the third electrical connection 13, the fourth electrical connection 14, the fifth electrical connection 15;

[0028] Wherein, the substrate 1 is formed by bonding an upper substrate, a middle substrate, and a lower substrate;

[0029] The closed cavity 2 is arranged inside the substrate 1;

[0030]The left end face of the first cantilever beam 3 is fixed with the left inner cavity wall of the closed cavity 2; the right end face of the second cantilever beam 4 is fixed with the right inner cavity wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com