Cloth-filling anti-detaching method

A cloth and anti-loosening technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of precipitation and poor reliability, and achieve the effect of improving EMI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

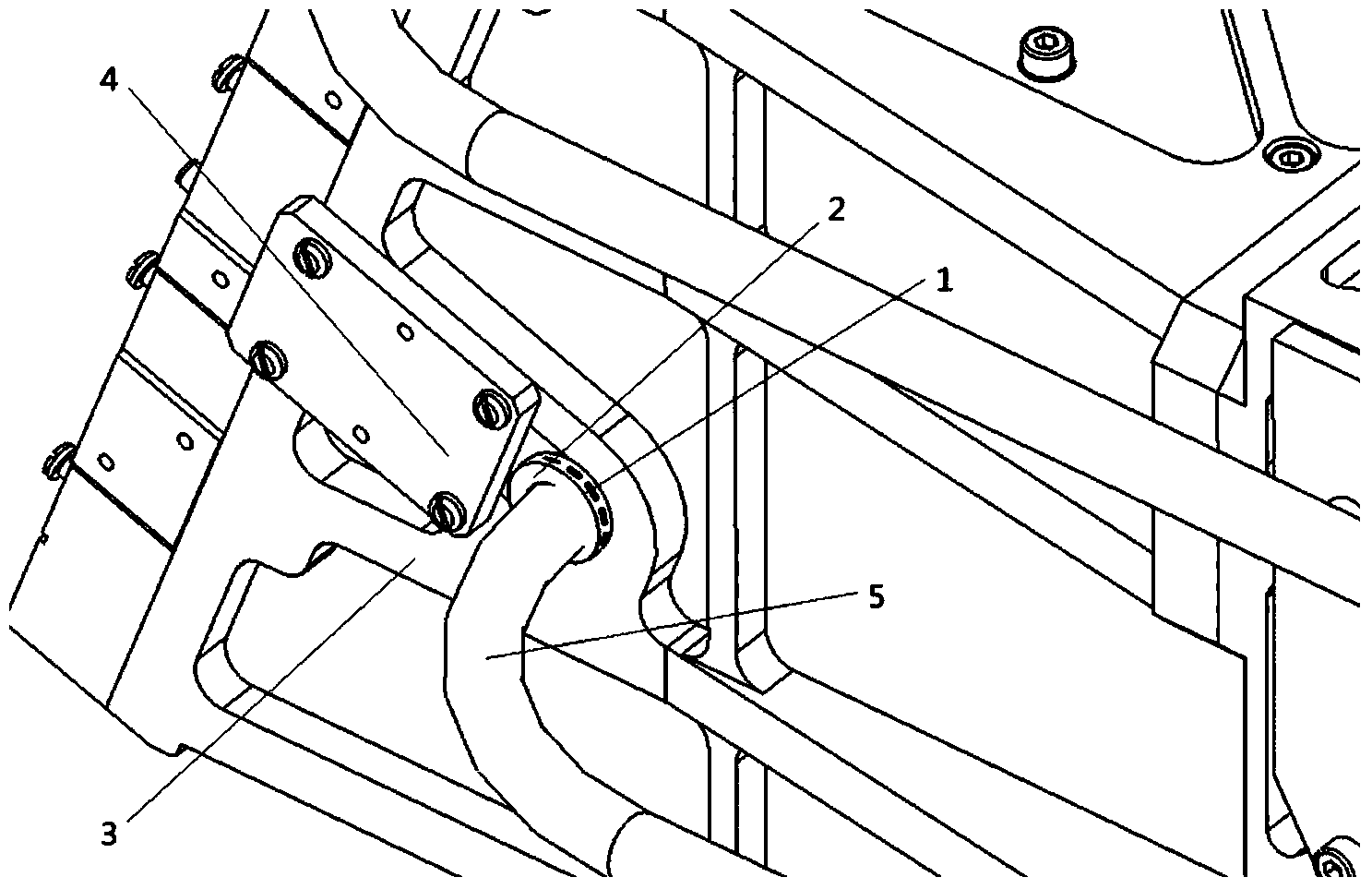

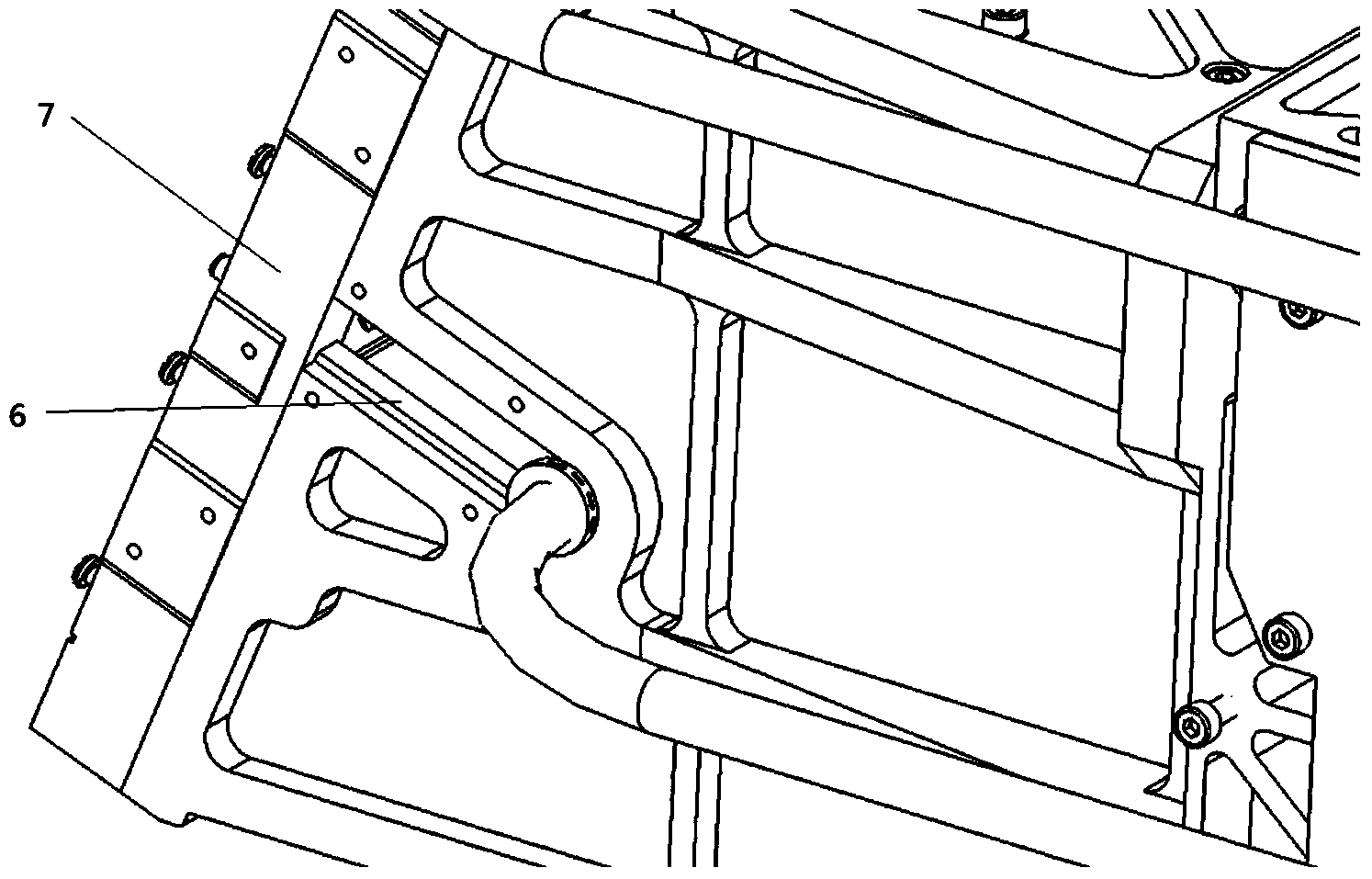

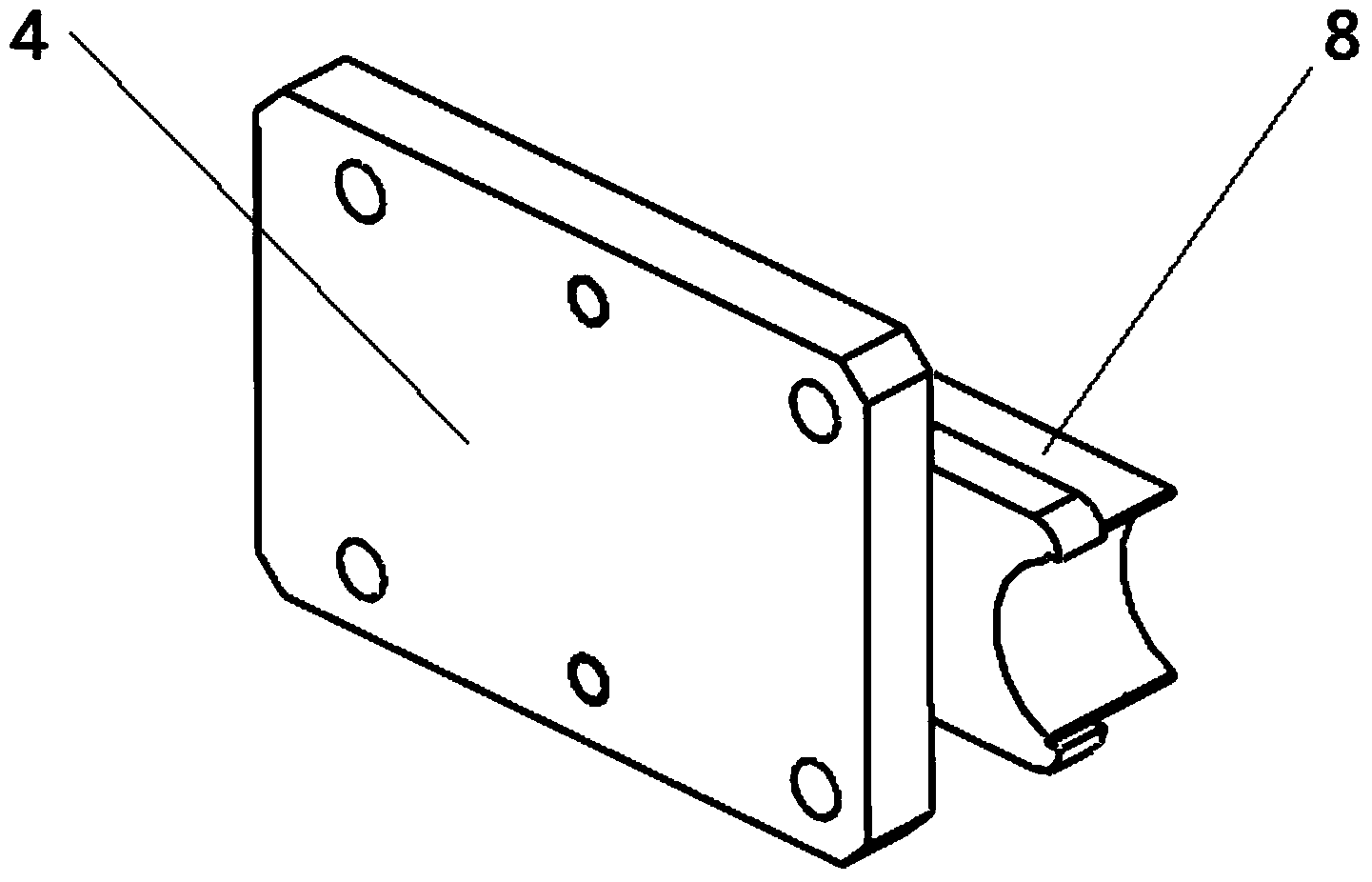

[0020] Specific implementation mode one, such as Figure 1-3 As shown, the cloth 2 is sewn by the flanging method through the line 1 to form a concave long cloth strip, the width of the concave part is equal to the housing installation groove 6, and the short side of the concave long cloth strip is parallel to the surface of the instrument part 5 Winding, and then put it into the installation groove 6 of the instrument case 3; install the instrument sub-housing 4, fix it through the sealing installation groove slider 8 on the back of the instrument sub-housing 4, and then install the sealing cover 7 to complete the gap. filling. The filling of fabric 2 should ensure that the sewn flanging part is placed on the outside of the gap and the thickness is greater than the width of the gap.

[0021] combine Figure 4 and Figure 5 As shown, the method described in this embodiment mode can also be used for filling plane gaps, and can be used superimposedly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com