A flyback converter and its control method

A technology of flyback converter and control method, applied in control/regulation system, conversion of DC power input to DC power output, instruments, etc., can solve the problem of large oscillation of flyback circuit, reduce the loss of switching tube and optimize EMI , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

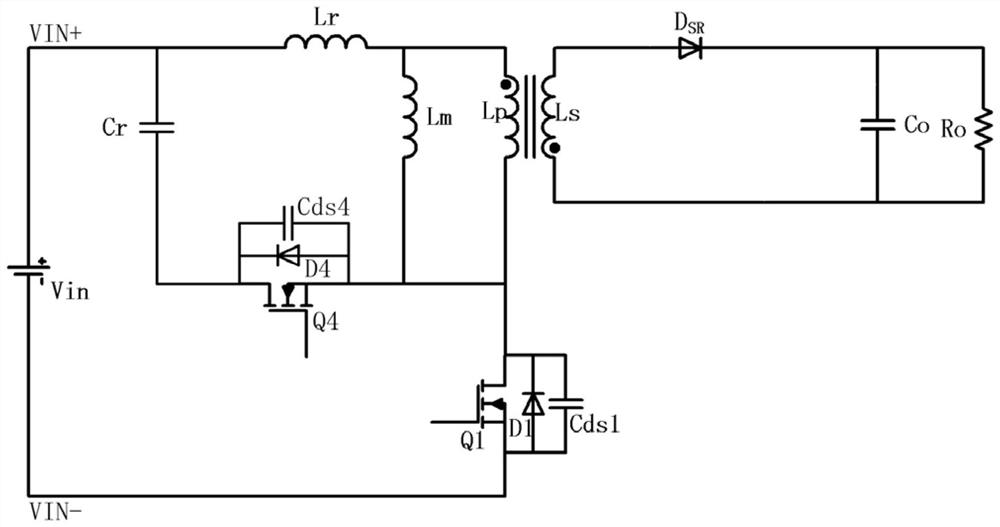

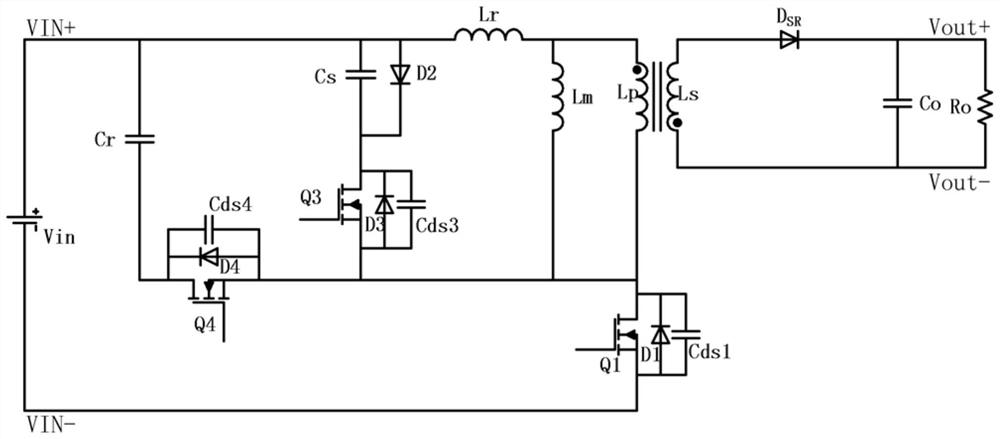

[0046] like figure 2 As shown, the present invention discloses a flyback converter, including a main power circuit, a clamping circuit and an output filter circuit; the main power circuit is provided with a transformer and a main switching tube Q1, and the clamping circuit is provided with a clamp Bit capacitor Cr and main clamping tube Q4, the first end of the primary winding Lp of the transformer is used as the positive input terminal VIN+ of the flyback converter, the second end of the primary winding Lp, the main switch The drain of the transistor Q1 is connected to the source of the main clamping transistor Q4, the drain of the main clamping transistor Q4 is connected to the positive input terminal VIN+ through the clamping capacitor Cr, and the main switching transistor Q1 The source of the flyback converter is used as the negative input terminal VIN- of the flyback converter; the secondary winding Ls of the transformer is used to output direct current to the load Ro th...

Embodiment approach

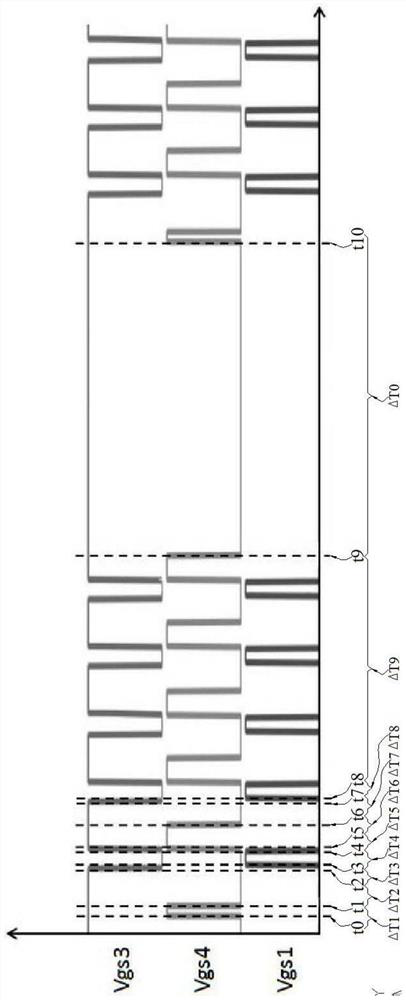

[0093] The ΔT1, ΔT3, ΔT5, ΔT6, and ΔT8 all take the minimum value, that is:

[0094] At the end of the first period, that is, at time t1, the excitation inductance Lm and leakage inductance Lr of the transformer are stored to the minimum energy required to realize the zero-voltage switching of the main switching tube Q1;

[0095] At the end of the third period, that is, at time t3, the voltage of the parasitic capacitance Cds1 of the main switching transistor Q1 drops to zero;

[0096] At the end of the fifth period, that is, at time t5, the drain-source voltage of the main switching transistor Q1 rises to Vin+Vc;

[0097] At the end of the sixth period, that is, at time t6, the secondary current of the transformer is reduced to zero;

[0098] At the end of the eighth period, that is, at time t8, the voltage of the parasitic capacitor Cds1 of the main switching transistor Q1 drops to zero.

[0099] It should be noted that the values of ΔT1 , ΔT3 , ΔT5 , and ΔT6 can also be...

Embodiment 3

[0101] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

[0102] The sum of the working time and the non-working time is a constant value T', and its value is set according to the design requirements of the flyback converter.

[0103] Preferably: the value of the number N of cycle periods in the working time increases with the increase of the load Ro, and ΔT0=T'-(ΔT3+ΔT4+ΔT5+ΔT6).

[0104] Therefore, when the load Ro is lighter, the duration of the working time is shorter, and the duration ΔT0 of the non-working time is longer, on the contrary, when the load Ro is heavier, the duration of the working time is longer, The shorter the duration ΔT0 of the non-working time, the equivalent operating frequency of the flyback converter changes in the same direction as the load Ro. Therefore, the switching tube loss of the flyback converter of the present invention can be reduced and the light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com