Reconfigurable mobile production system and production method of concrete prefabricated components

A technology for production systems and prefabricated components, which is applied in building construction, construction, processing of building materials, etc., and can solve problems such as no technical solutions are given.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

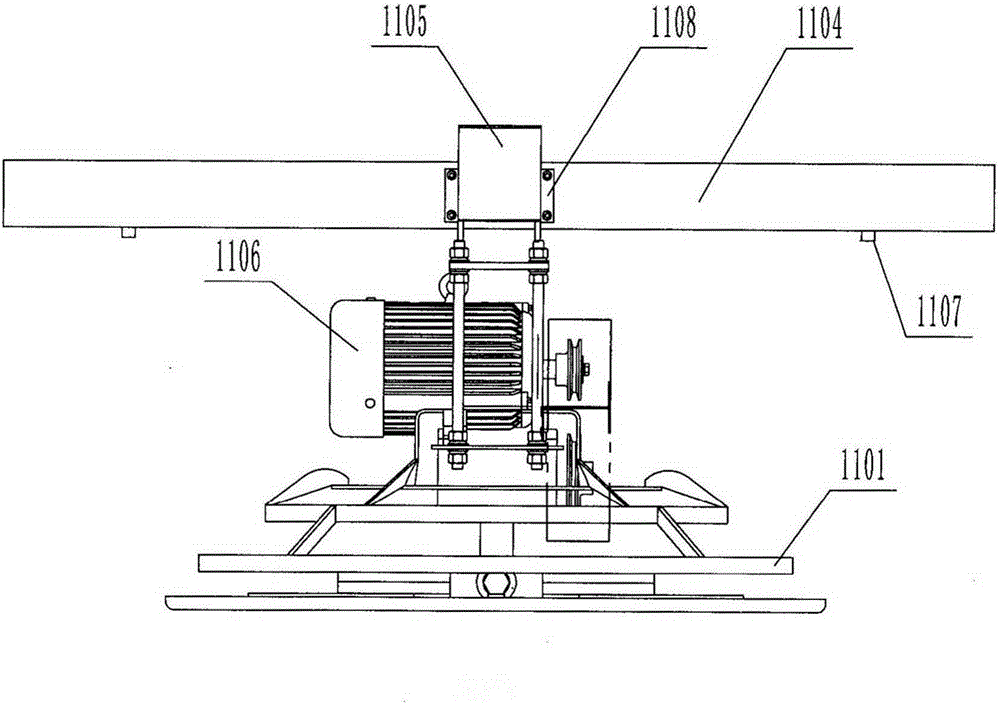

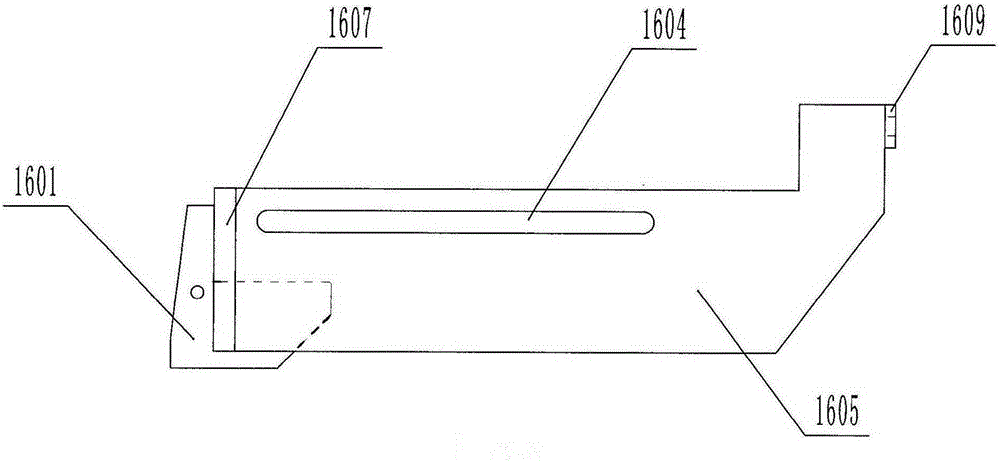

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the recombinable mobile (nomadic) production system of prefabricated concrete components of the present invention has a mobile distributing machine 4, a surface treatment integrated machine 5 for vibrating, scraping and smoothing concrete materials, and a mobile turning machine 6. Several mold tables 3 supported by the ground, two first rails 1 installed on the ground, and two second rails 2 installed on the ground. The mobile distributing machine 4 and the surface treatment integrated machine 5 running on the same track are arranged on two first tracks 1, and the mobile turning machine 6 is arranged on two second tracks 2, and the above-mentioned several The mold table 3, the mobile distributing machine 4, the surface layer treatment integrated machine 5, and the mobile turning machine 6 are arranged in sequence; each mold table has a table top, a front leg 301 placed on the ground at its front and rear si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com