An assembled waterproof roll machine

A waterproof membrane and assembled technology, which is applied in the direction of protection devices, devices for coating liquid on the surface, roofing, etc., can solve the problem that the control of the thickness of the waterproof system cannot be realized, the waterproof membrane cannot be achieved, and the construction equipment of the waterproof system cannot be realized. Disassembly, installation and handling and other issues, to achieve the effect of improving waterproof quality, convenient cleaning and maintenance, and precise thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

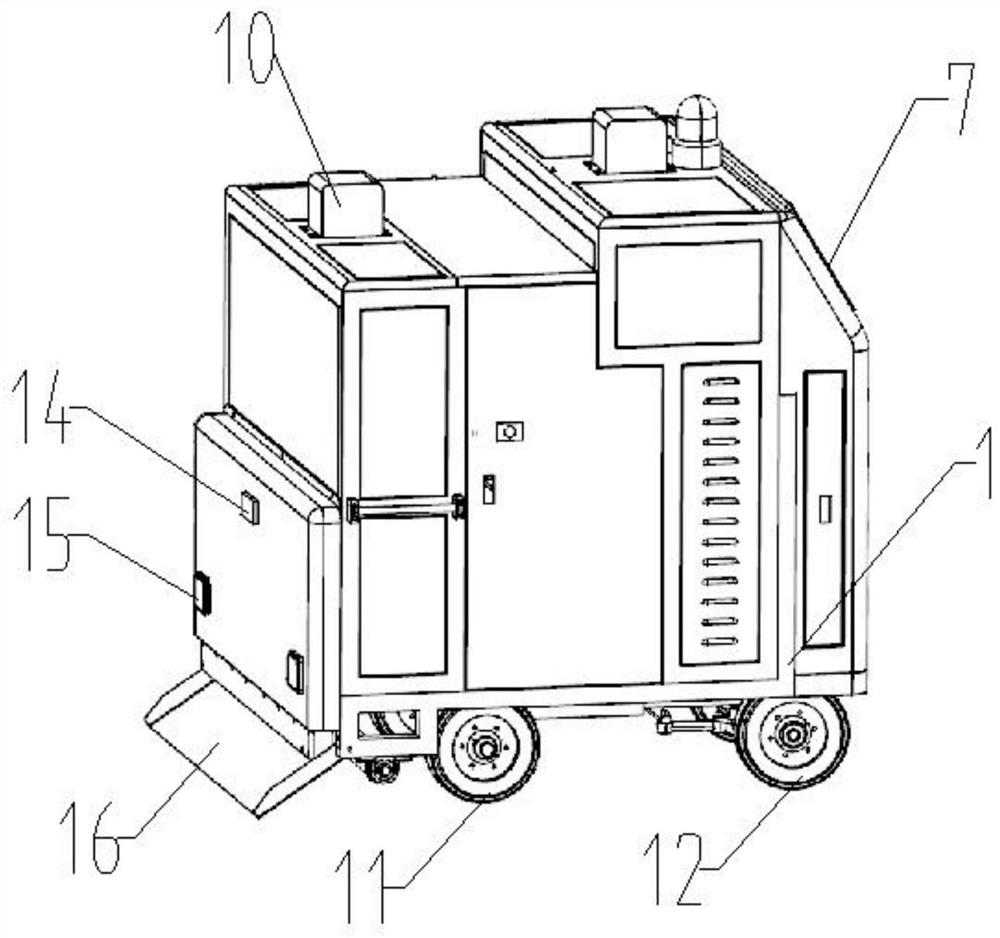

[0044] Such as Figure 1-6 As shown, an assembling type ready-made waterproof coiled material machine includes a frame 1, a top coating mechanism 3, a walking mechanism, a coating mechanism 4, and a bottom coating mechanism 2. The frame 1 includes a bottom plate 101 and a side plate 102, The front end of the bottom plate 101 is fixedly connected with the lower end of the side plate 102; a walking mechanism is arranged under the bottom plate 101; the bottom coating mechanism 2, the coating mechanism 4, and the top coating mechanism 3 are detachably installed above the bottom plate 101 in order from the end of the side plate 102; The bottom coating mechanism 2 is a mechanism for coating bottom waterproof coating; the coating mechanism 4 is a mechanism for transporting coils; and the top coating mechanism 3 is a mechanism for coating top waterproof coating.

[0045] When assembling on site, the frame 1, the top coating mechanism 3, the coating mechanism 4, and the primer mechanism 2...

Embodiment 2

[0050] On the basis of the above embodiment, such as Figure 1-6 As shown, the coating mechanism 4 and the primer mechanism 2 are arranged in pairs, and there are more than two pairs. The primer mechanism 2 at the front end abuts the side plate 102, and the coating mechanism 4 at the rear end is in contact with the top coating mechanism 3. When abutting, the coating mechanism 4 and the primer mechanism 2 between the two ends abut against each other. The modular design can not only realize the construction of one-cloth two-coating waterproof system, but also expand the construction of more complex waterproof systems such as two-cloth three-coating, three-cloth four-coating and so on.

[0051] Such as Figure 7 , Exemplarily presents a two-cloth and three-coating ready-made waterproof membrane machine, the coating mechanism 4 and the primer mechanism 2 are two pairs, respectively the first coating mechanism 4001 and the second coating mechanism 4002, the first One primer coating m...

Embodiment 3

[0054] On the basis of the above-mentioned embodiment, the coating mechanism 4 and the top coating mechanism 3 are arranged in pairs, and there are more than two pairs. One end of the bottom coating mechanism 2 at the front end abuts against the side plate 102, and the coating at the second front end The mechanism 4 abuts against the other end of the primer mechanism 2 at the front end, and the coating mechanism 4 and the top coat mechanism 3 at the rear abut against each other.

[0055] Such as Figure 8 , Exemplarily gives another two-cloth and three-coating ready-made waterproof membrane machine, the coating mechanism 4 and the top coating mechanism 3 are two pairs, respectively the first coating mechanism 4001 and the second coating mechanism 4002, The first top coating mechanism 3001 and the top coating mechanism 3002, one end of the foremost primer mechanism 2 abuts against the side plate 102, the other end abuts one end of the first coating mechanism 4001, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com