Pure cotton PVA low-concentration and room-temperature sizing method

A low-concentration, normal-temperature technology, applied in the direction of liquid/gas/steam yarn/filament processing, plant fiber, etc., can solve the problems of high sizing rate, high process energy consumption, difficult desizing in finishing process, etc., and achieve energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: Select 1500 meters of 80-inch strands for sizing, and the PVA size concentration is 1.5%.

[0010] 1. Slurry mixing process: add 1000 liters of water into the slurry mixing tank, and raise the temperature to 50°C, turn on the agitator, then add 10 kg of PVA, stop heating after the temperature rises to 90°C, continue to stir for 15 minutes, then stop stirring to make PVA 1% slurry.

[0011] 2. Sizing process: Use the sizing machine to put the prepared slurry in the sizing barrel into the size tank, and at the same time turn on the circulation pump, turn off the heating device in the size tank, and start the sizing machine normally for sizing.

Embodiment 2

[0012] Embodiment 2: Select 5600 meters of 100-inch strands for sizing, and the PVA size concentration is 2%.

[0013] 1. Slurry mixing process: add 1000 liters of water into the slurry mixing tank, and raise the temperature to 50°C, turn on the agitator, then add 20 kg of PVA, stop heating after the temperature rises to 90°C, continue to stir for 15 minutes, then stop stirring to make PVA A slurry with a consistency of 2%.

[0014] 2. Sizing process: Pour the PVA slurry with a concentration of 2% in the sizing tank into the size tank, turn on the circulation pump at the same time, turn off the heating device in the size tank, and start the sizing machine normally.

Embodiment 3

[0015] Embodiment 3: Select 1000 meters of 40-inch single yarn for sizing, and the PVA size concentration is 4%.

[0016] 1. Slurry mixing process: add 1000 liters of water into the slurry mixing tank, and raise the temperature to 50°C, turn on the agitator, then add 40 kg of PVA, stop heating after the temperature rises to 90°C, continue to stir for 15 minutes, then stop stirring to make PVA 4% slurry.

[0017] 2. Sizing process: Put the PVA slurry with a concentration of 4% adjusted in the sizing tank into the size tank, turn on the circulation pump at the same time, turn off the heating device in the size tank, and start the sizing machine normally.

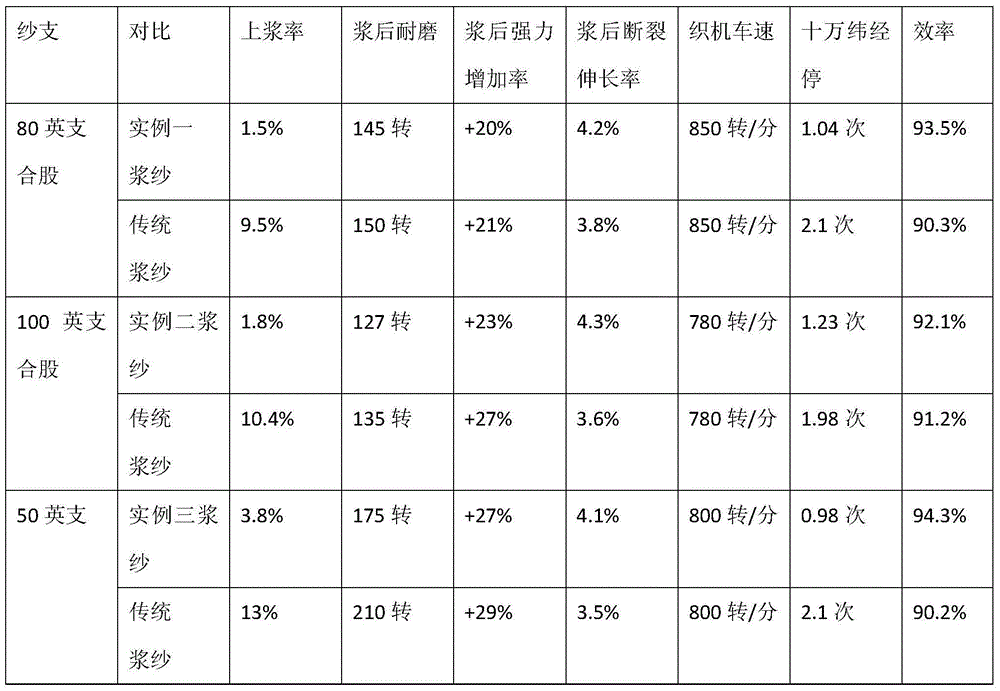

[0018] After testing, the yarn processed by the present invention has the following data compared with traditional sizing:

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com