Method for improving production capacity of 2-KGA (2-keto-L-gulonic acid) through enhancement of Ketogulonogeniumvulgarum carbon metabolism level

A technology of keto-gulonic acid bacteria and gulon acid, which is applied in the field of transforming vitamin C fermentation technology, and can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

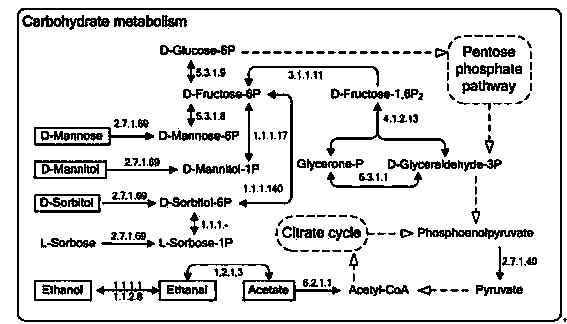

Method used

Image

Examples

Embodiment 1

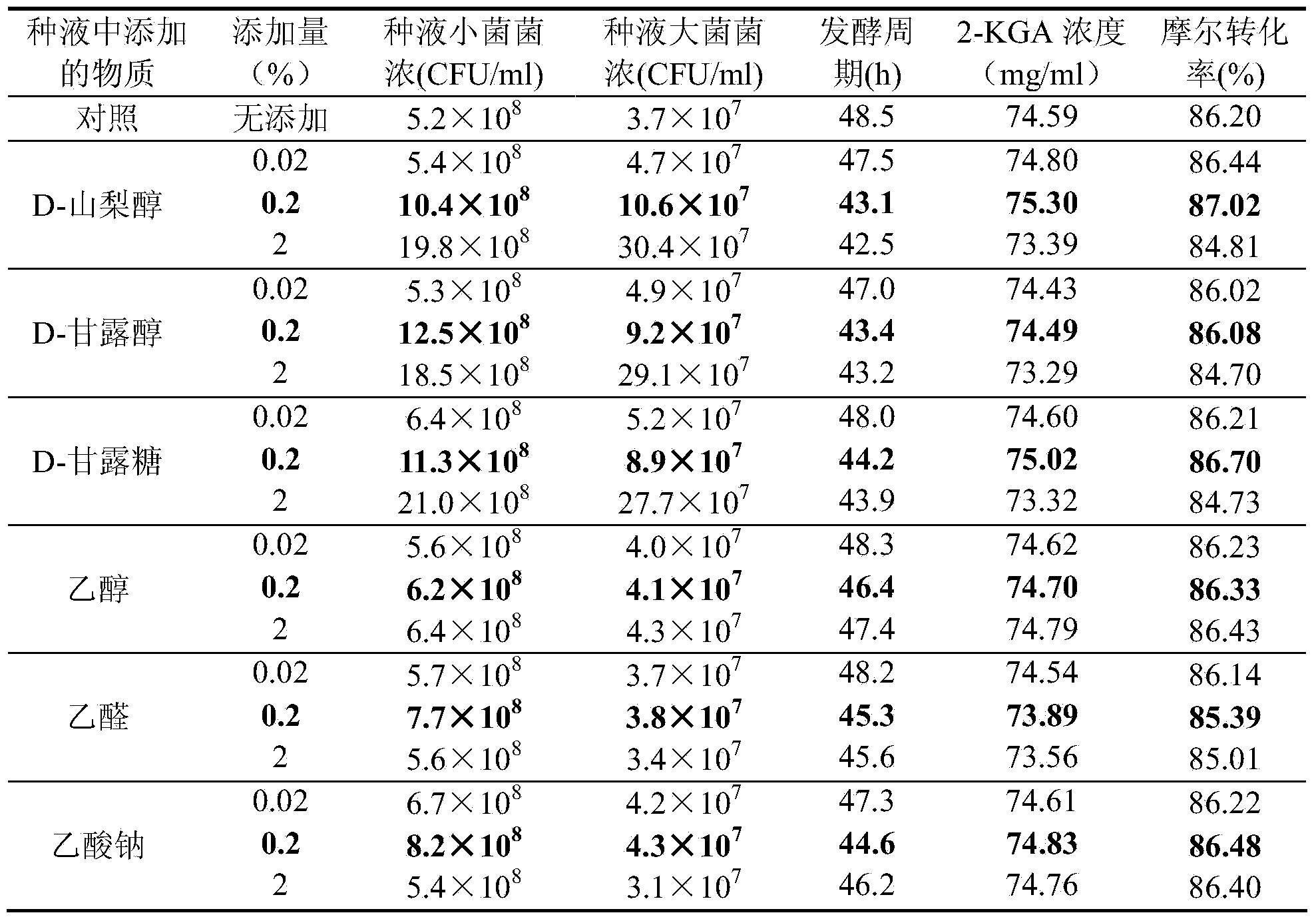

[0026] Implementation Example 1: Investigate the impact of adding two-carbon and six-carbon units on the ability to produce 2-KGA in conventional seed solution under single factor conditions

[0027] The concentrations of the above-mentioned two-carbon and six-carbon unit carbon sources added to each conventional seed medium were 0.02%, 0.2%, and 2% in sequence.

[0028] Conventional seed medium is: 2% L-sorbose, 0.5% corn steep liquor, 0.2% glucose, 0.1% urea, 0.2% calcium carbonate, pH6.7-7.0.

[0029] The conventional fermentation medium is: 8% L-sorbose, 1.5% corn steep liquor, 0.1% potassium dihydrogen phosphate, 0.1% urea, 0.01% magnesium sulfate, 0.5% calcium carbonate, pH6.7-7.0.

[0030] Culture conditions: the slant of the mixed bacteria culture was inoculated in common seed liquid medium with different two-carbon or six-carbon units, 30°C, 220 rpm, shake flask culture for 20 hours to make seed liquid, 10% was inoculated in ordinary fermentation In the culture mediu...

Embodiment 2

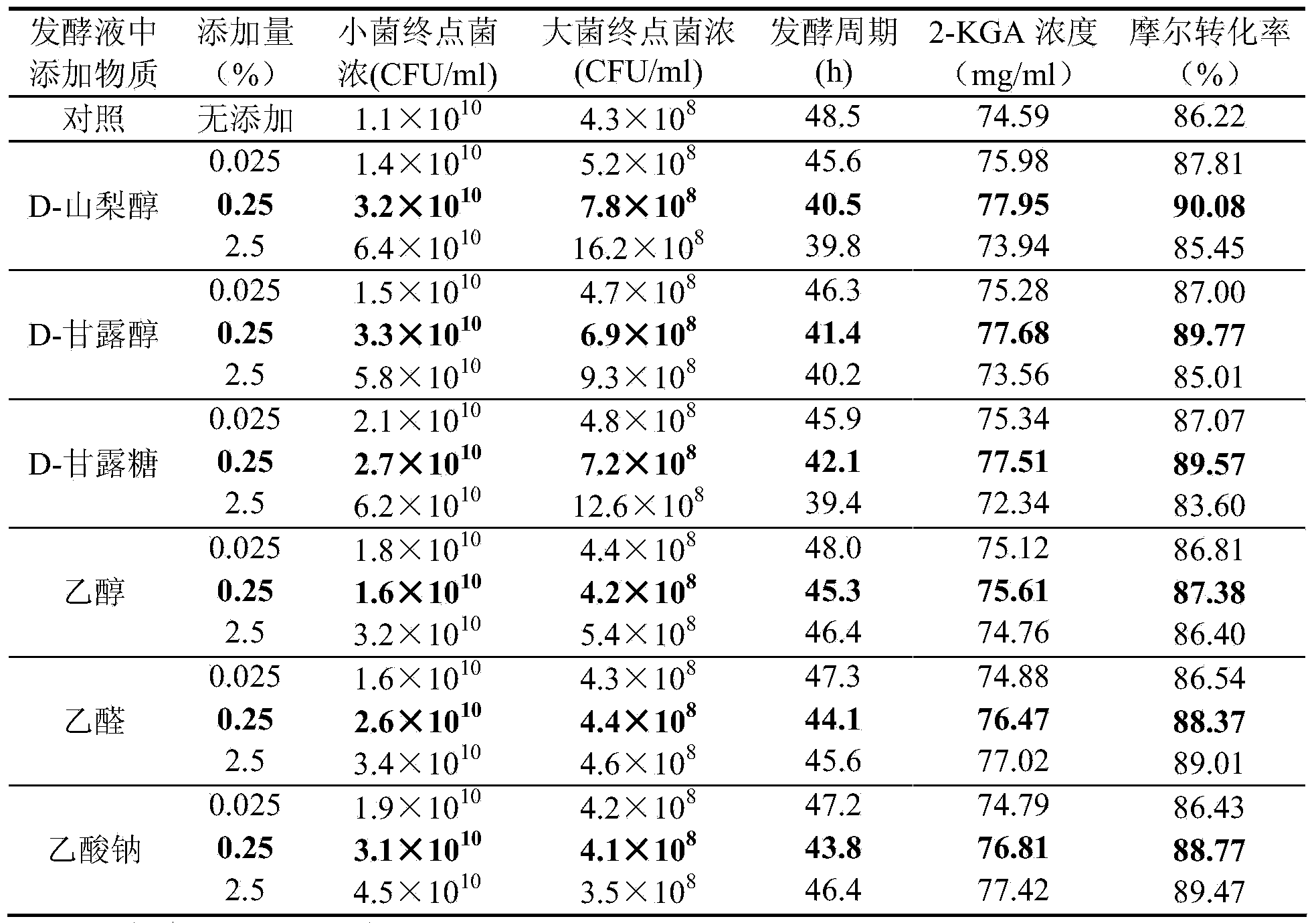

[0035] Implementation Example 2: Investigate the impact of adding two-carbon and six-carbon units on the ability to produce 2-KGA in conventional fermentation broth under single factor conditions

[0036] The above-mentioned two-carbon and six-carbon unit carbon sources were respectively added to each conventional fermentation medium at a concentration of 0.025%, 0.25% and 2.5%.

[0037] Conventional seed medium: see Example 1.

[0038] Conventional fermentation medium is: referring to example 1.

[0039] Culture conditions: see Example 1. The experimental results are shown in Table 2.

[0040] Table 2. Under single factor conditions, the effects of adding 0.025%, 0.25% and 2.5% two-carbon and six-carbon unit carbon sources on fermentation in the fermentation broth

[0041]

[0042][Note] The bold font is the effect of the optimum concentration of active substances on fermentation.

[0043] It can be seen from Table 2 that the above-mentioned 6 kinds of carbon sources al...

Embodiment 3

[0044] Implementation example 3: The effect of adding the optimized combination of two carbon and six carbon units to the seed liquid or fermentation liquid on the ability to produce 2-KGA

[0045] Conventional seed medium: see Example 1.

[0046] Conventional fermentation medium is: referring to example 1.

[0047] Culture conditions: see Example 1.

[0048] Using the orthogonal analysis method to add different combinations of two-carbon and six-carbon units in the seed solution, and taking the fermentation period of the fermentation broth as the result, investigate the effect of adding different combinations of two-carbon and six-carbon units in the seed solution on the final fermentation cycle. The experimental results are shown in table 3.

[0049] Table 3.L 32 Orthogonal analysis results of (4^6) 4 levels and 6 factors seed solution adding 2-carbon and 6-carbon unit combinations.

[0050]

[0051]

[0052] [Note] The bold font is the effect of the optimum concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com