Laboratory continuous biogas anaerobic fermentation device

An anaerobic fermentation and laboratory-used technology, applied in the field of fermentation, can solve problems such as the difficulty in realizing the raw material temperature of the fermentation tank, insufficient biogas firepower, and backward production technology, so as to facilitate the production of biogas, improve fermentation efficiency and gas production rate, and ensure heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

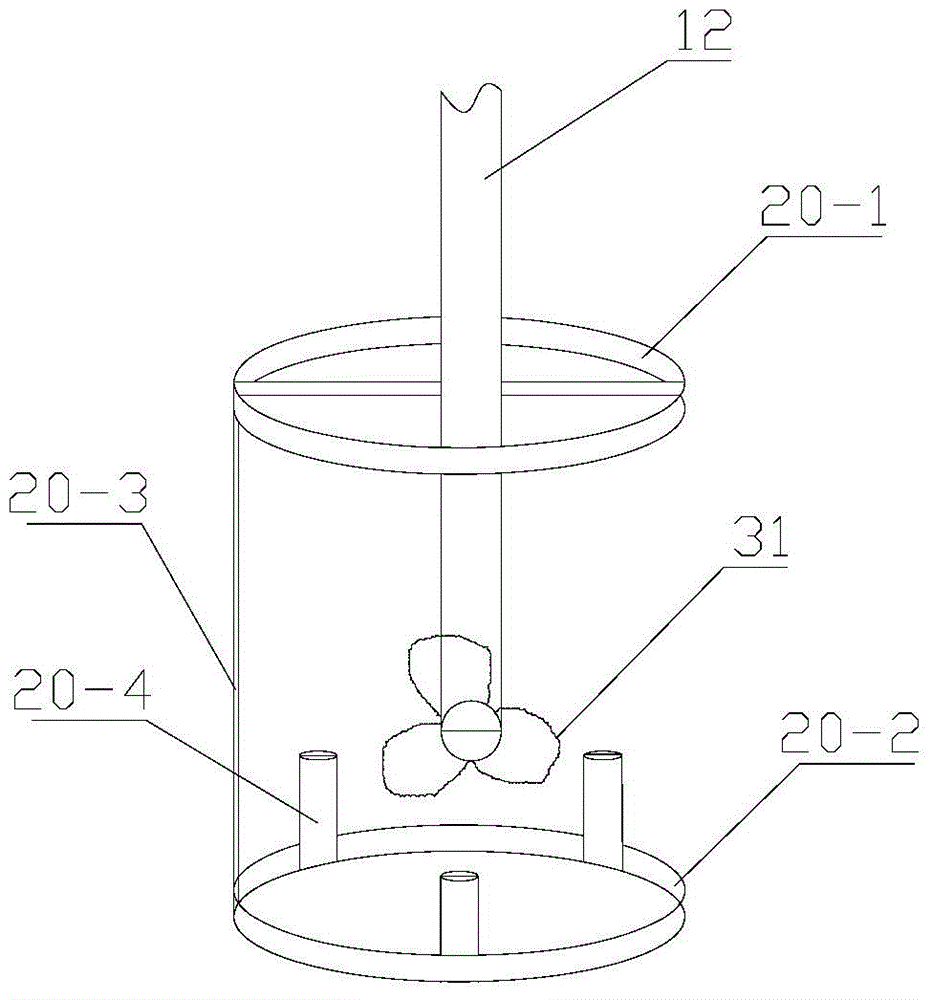

[0047] Such as figure 1 and figure 2 As shown, the present invention includes a first space, a second space and a third space arranged at intervals, and the middle part of the first space is provided with a gas collection and storage chamber 27 for separating the upper and lower parts of the first space to form an upper part and The dividing plate 26 of the lower feeding chamber 28, the second space is a fermentation chamber 29, the periphery of the second space is provided with an insulating layer, and the third space is a biogas residue biogas liquid chamber 30; the fermentation chamber 29 A fermenter 19, a fermentation temperature controller 21 and a vertical mixer 12 installed on the fermenter 19 are arranged inside, the stirring rod of the vertical mixer 12 is inserted into the inside of the fermenter 19, and the motor of the vertical mixer 12 Supported on the top of the fermenter 19 tank body, the bottom of the stirring rod of the vertical mixer 12 is equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com