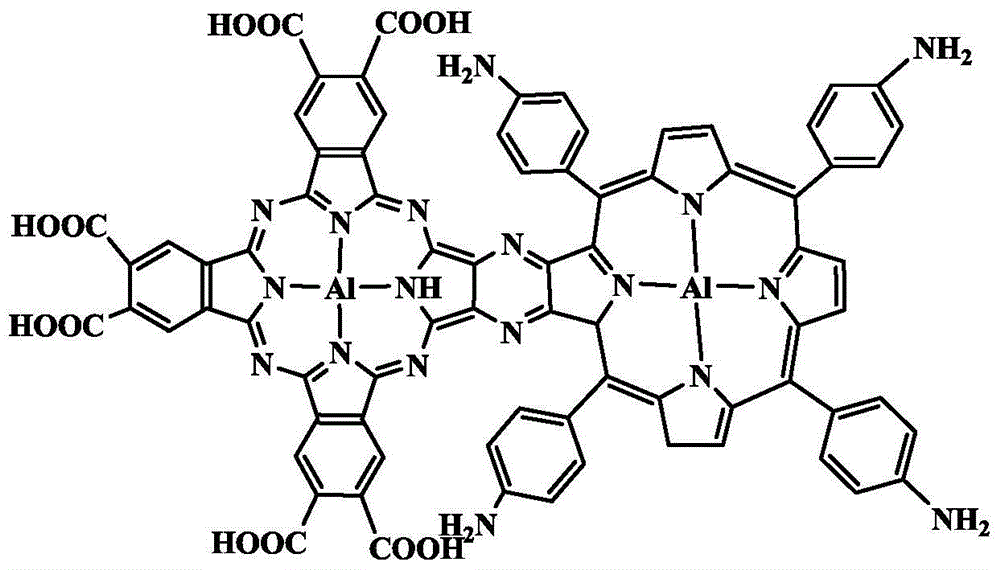

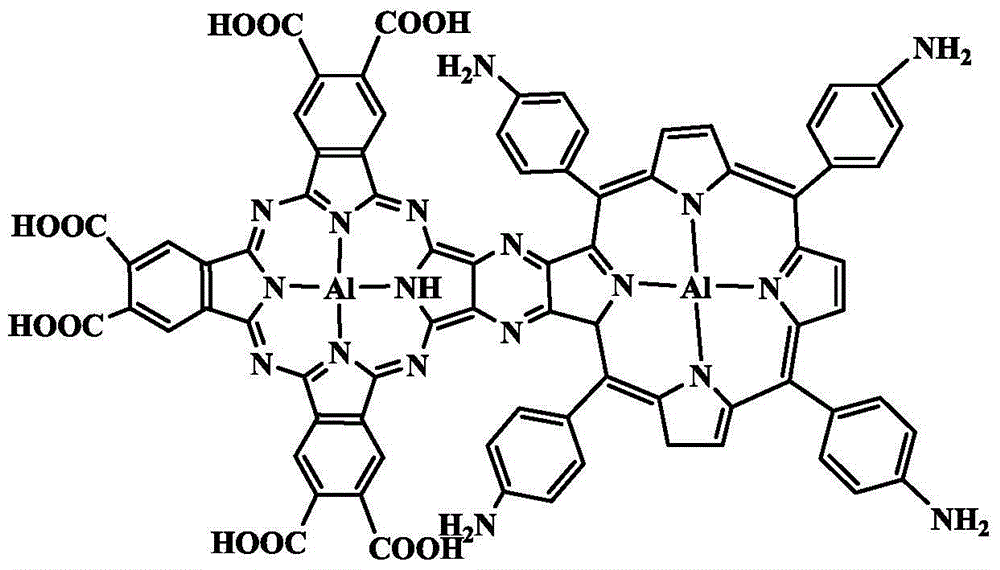

Micro-printing method by using water soluble planar conjugated phthalocyanine porphyrin diad as micro-contact printing ink

A technology of micro-contact printing and plane conjugation, which is applied in the direction of transferring inks, inks, and household appliances from manuscripts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. The substrate is polytetrafluoroethylene, 100g of the substrate material is ultrasonically cleaned with 500g of ethanol for 1 hour, then taken out, vacuum-dried at 80°C, and soaked in 500g of 5wt% γ-aminopropyltriethoxysilane ethanol Take it out and wash it with ethanol, soak it in 1000g polyacrylic acid aqueous solution with a concentration of 1g / L for 1 hour, take it out and dry it at 100°C.

[0029] 2. Dissolve 5,10,15,20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum phthalocyanine in water to obtain 0.2wt% 5,10,15,20-p-aminophenylporphyrin zinc hexacarboxy Zinc phthalocyanine.

[0030] 3. Soak the PDMS stamp in the aqueous solution of 5, 10, 15, 20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum for 30s, take it out and dry it in the N2 airflow for 30s, and apply 5, 10, 15, The PDMS stamp of 20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum aqueous solution is covered on the carboxylated substrate, and ...

Embodiment 2

[0033] 1. The substrate is polytetrafluoroethylene, 100g of the substrate material is ultrasonically cleaned with 700g of ethanol for 1 hour, then taken out, and vacuum-dried at 80°C. Soak the substrate in 700g of 5wt% gamma-aminopropyltriethoxysilane ethanol for 24 hours, take it out and wash it with ethanol, soak it in 1000g of polyacrylic acid aqueous solution with a concentration of 10g / L for 1 hour, take it out and dry it at 100°C.

[0034] 2. Dissolving 5,10,15,20-p-aminophenylporphyrin alumino-hexacarboxyphthalocyanine aluminum in water to obtain 5,10,15,20-p-aminophenylporphyrin zinc-porphyrin with a concentration of 0.5wt% Zinc hexacarboxyphthalocyanine.

[0035] 3. Soak the PDMS stamp in the aqueous solution of 5, 10, 15, 20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum for 35s, take it out and put it in N 2 Dry in airflow for 45s, cover the PDMS stamp coated with 5, 10, 15, 20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum a...

Embodiment 3

[0038] 1. The substrate is polytetrafluoroethylene, 100g of the substrate material is ultrasonically cleaned with 1000g of ethanol for 1 hour, then taken out, and vacuum-dried at 80°C. Soak the substrate in 1000g of 5wt% gamma-aminopropyltriethoxysilane ethanol for 24 hours, take it out and wash it with ethanol, soak it in 1000g of polyacrylic acid aqueous solution with a concentration of 20g / L for 1 hour, take it out and dry it at 100°C.

[0039] 2. Dissolving 5,10,15,20-p-aminophenylporphyrin alumino-hexacarboxyphthalocyanine aluminum in water to obtain 5,10,15,20-p-aminophenylporphyrin zinc-porphyrin with a concentration of 0.8wt% Zinc hexacarboxyphthalocyanine.

[0040] 3. Soak the PDMS stamp in the aqueous solution of 5,10,15,20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum for 40s, take it out and put it in N 2 Dry in airflow for 30-60s, cover the PDMS stamp coated with 5,10,15,20-p-aminophenylporphyrin aluminum hexacarboxyphthalocyanine aluminum aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com